-

Tools/supplies

-

Drilling, polishing, grinding

-

Turning

-

Facilities, compressed air and vacuum

-

Goldsmith special tools/GRS

-

Small tools

-

Soldering, melting, casting, welding

-

Measuring and testing

-

Surface treatment

-

Clean, dry, turning, sawing

-

CAD-software / software

-

Watchmaker tools

- Sales and workshop tools

-

3D Werkzeuge & Reinigung

-

Drilling, polishing, grinding

Retaining adhesive LOCTITE 638, 10ml

Product number:

359706

Packaging Unit:

1

From Stock

| Application: | high strength, high temperature resistant, oil tolerant |

|---|---|

| Article name: | Retaining adhesive |

| Brand: | Loctite |

| Colour: | green |

| Content: | 10,00 |

| Manufacturer name: | Loctite 638 |

| Special feature: | touch proof in about 4 minutes, gap 0.25mm |

| Unit content: | ml |

Manufacturer Informations

Name: Henkel AG & Co. KGaA

Street: Henkelstr. 67

City: 40589 Düsseldorf

Country: DE

Email: info@henkel.com

Phone: 0049-211-797-0

0 of 0 reviews

Login

No reviews found. Be the first to share your insights.

Product information "Retaining adhesive LOCTITE 638, 10ml"

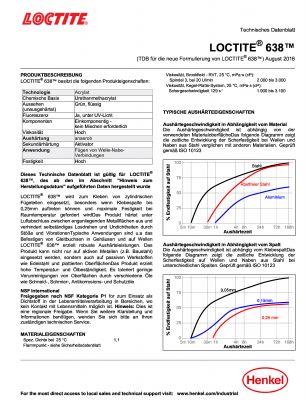

LOCTITE 638 is a high-strength, fast-curing, universal retaining compound.

LOCTITE® 638 is used for bonding cylindrical parts, particularly when there are gaps of around 0.25 mm. The product hardens in the absence of air between close-fitting metal surfaces and prevents it from loosening and leaks caused by impact and vibration. It can be used not only on active metals but also on passive materials and achieves robust curing performance. The product offers high temperature resistance and good oil tolerance and tolerates minor surface contamination.

• Tolerates minor surface contamination, including industrial oils

• High strength on all metals, even on passive materials (e.g. stainless steel)

• High temperature resistance

• Ideal for parts used in transmissions, engines or similar applications

• DVGW approval (EN 751-1): NG-5146AR0619

• P1 NSF Reg. No.: 123010

• WRAS Approval (BS 6920): 0511518

• Maximum adhesive gap: 0.25 mm

• Handling strength on steel: 4 minutes

• Tensile shear strength: >25 N/mm²

• Operating temperature range: -55°C to +180°C

• Color green

LOCTITE® 638 is used for bonding cylindrical parts, particularly when there are gaps of around 0.25 mm. The product hardens in the absence of air between close-fitting metal surfaces and prevents it from loosening and leaks caused by impact and vibration. It can be used not only on active metals but also on passive materials and achieves robust curing performance. The product offers high temperature resistance and good oil tolerance and tolerates minor surface contamination.

• Tolerates minor surface contamination, including industrial oils

• High strength on all metals, even on passive materials (e.g. stainless steel)

• High temperature resistance

• Ideal for parts used in transmissions, engines or similar applications

• DVGW approval (EN 751-1): NG-5146AR0619

• P1 NSF Reg. No.: 123010

• WRAS Approval (BS 6920): 0511518

• Maximum adhesive gap: 0.25 mm

• Handling strength on steel: 4 minutes

• Tensile shear strength: >25 N/mm²

• Operating temperature range: -55°C to +180°C

• Color green