-

Craft & creative

-

Advent calendar

-

Everything about molding

-

Everything about wood

-

Handicraft sets and tools

-

Poker work

-

Encaustic

-

Experiments

-

Colors & polish

-

Galvanizing

-

(Glass) Engraving

-

Kerzen gießen

-

Adhesives

-

Crib construction

-

Jigsaw

-

Soldering & welding

-

Model kits

-

Collector models

-

Sharpening

-

Writing instruments

-

Soap casting

-

teifoc stone building sets

-

Gilding

- Tools & machines

-

Pouring tin - material and equipment

-

Advent calendar

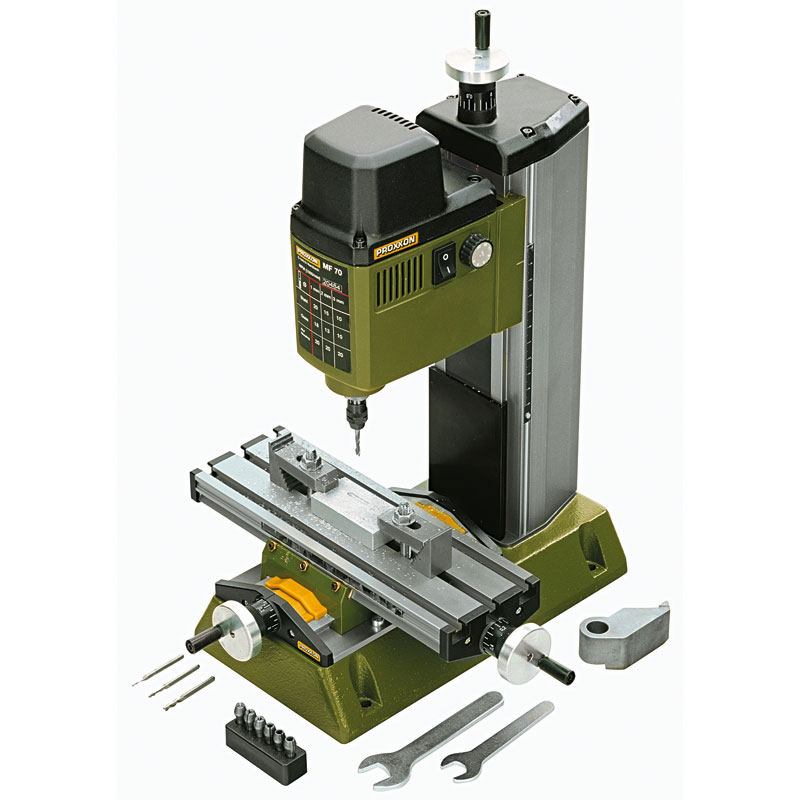

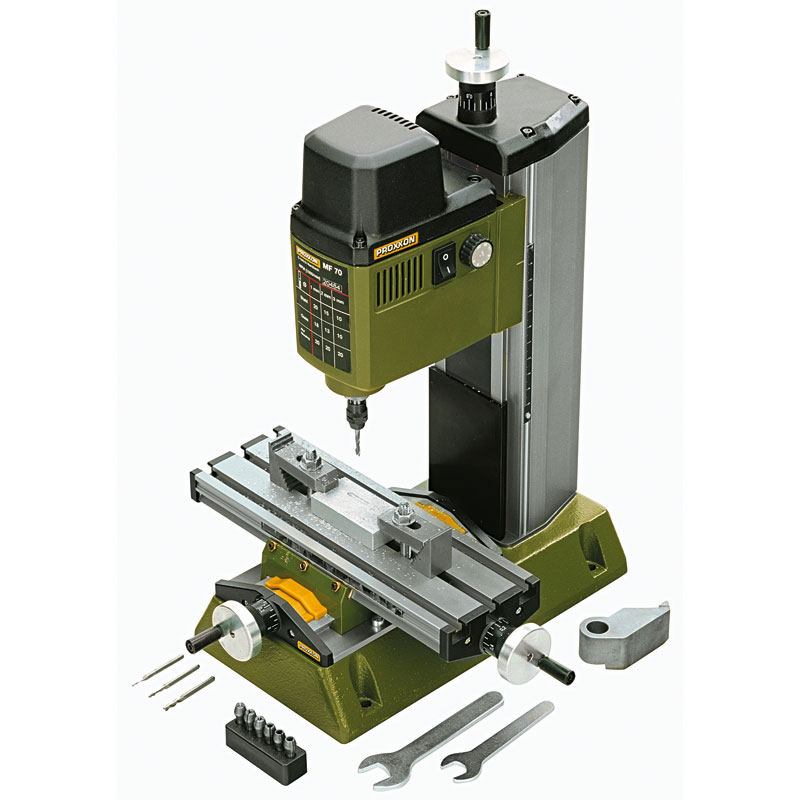

MICRO Milling Machine MF 70 PROXXON

Product number:

335844

Packaging Unit:

1

From Stock

- Description The MICRO Milling Machine MF 70 from PROXXON. Small but nice: the precise vertical milling machine for laboratories, opticia… More

- Reviews

-

Productvideos

By viewing the video you agree that your data will be transferred to youtube and that you have read the Privacy policy.

By viewing the video you agree that your data will be transferred to youtube and that you have read the Privacy policy.

![PROXXON MICRO-Fräse MF 70 PROXXON MICRO-Fräse MF 70]()

![PROXXON MICRO miller MF 70 PROXXON MICRO miller MF 70]()

| Article name: | MICRO Milling Machine MF 70 |

|---|---|

| Brand: | Proxxon |

| Content: | 1,00 |

| Dimensions height mm: | 370,00 |

| Dimensions width mm: | 70,00 |

| External dimension length: | 200,00 |

| Gross weight grams: | 0,00 |

| Manufacturer name: | MF 70 |

| Speed R/min: | 5000 - 20000 |

| Volt/Hz: | 220-240 |

| Watt: | 100 |

Manufacturer Informations

Name: Proxxon Werkzeug GmbH

Street: Dieselstr. 3-7

City: 54343 Föhren

Country: DE

Email: office@proxxon.com

Phone: 06502-93170

0 of 0 reviews

Login

No reviews found. Be the first to share your insights.

Accessoires (optional)

slide 7 to 9 of 4

The MICROMOT step clamps made of steel by PROXXON.

Complete with 2 step blocks and clamps, threaded bolts, nuts and T-slot nuts for the MICROMOT standard.

made of high quality steel

Further information

Suitable for MICROMOT milling and turning systems.

Vice, jaw width 50mm, clamping width 34 mm

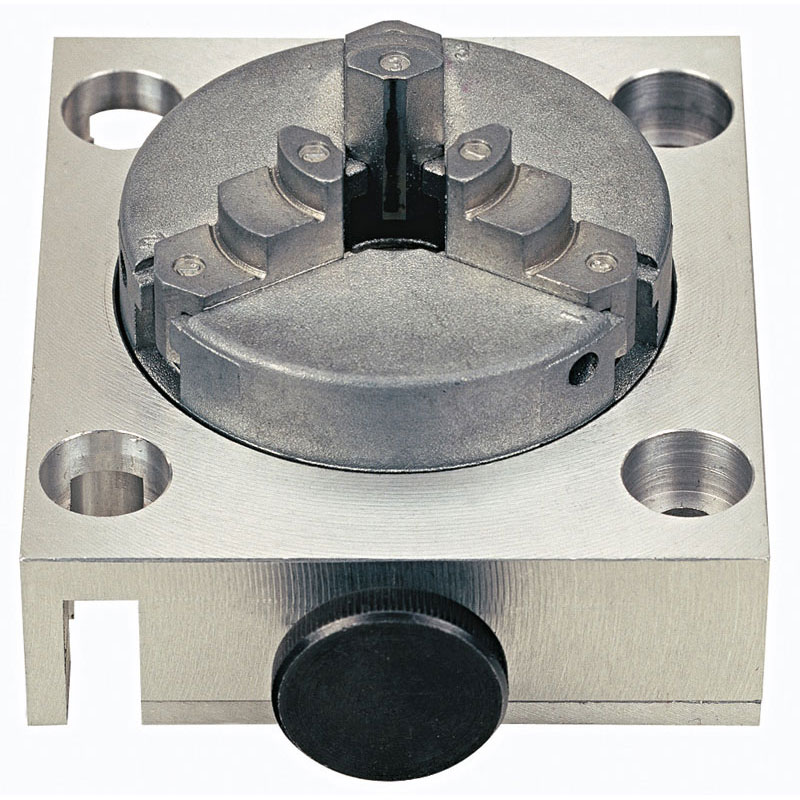

The dividing head of PROXXON. Ideal for the MF 70 and KT 70 microfrills.

For machining circular workpieces, producing radially offset holes and cutouts, milling of wrench flats, square edges, hexagonal edges, etc. Precise parting by vernier on the base body.

Chuck with reversible jaws: Clamping range inside 1.5 to 32 outside 12 to 65 mm. Recess for chuck 11 mm (for working longer shafts in vertical position). With mounting holes for horizontal and vertical mounting as well as suitable slot nuts and mounting screws for mounting on the MF 70 MICRO router and the KT 70 MICRO coordinate table. Supplied in a wooden box with sliding cover.

Precise dividing by nonius on the base body

11 mm recess for chuck

With mounting holes and screws

Internal clamping range: 1.5 to 32 mm

Clamping range outside: 12 to 65 mm

Size: 72 x 64 x 38 mm

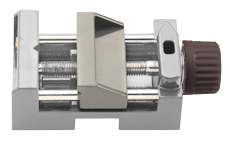

Precision machine vice PM 40 from PROXXON.

Absolutely angled. Also hang laterally and frontally. With matching slot nuts and fastening screws for T-slots to MICROMOT standard (12 x 6 x 5 mm).

Particularly suitable for filigree and exact work with the MICRO Milling Machine MF 70 or the MICRO coordinate table KT 70. Packed in a wooden box with sliding lid.

Milled steel. Jaw width 46 mm, wingspan 30 mm. With matching sliding blocks and fixing screws.

Special features

Especially suitable for PROXXON MICRO Milling Machine MF 70 and PROXXON MICRO coordinate table.

The MICROMOT step clamps made of steel by PROXXON.

Complete with 2 step blocks and clamps, threaded bolts, nuts and T-slot nuts for the MICROMOT standard.

made of high quality steel

Further information

Suitable for MICROMOT milling and turning systems.

Vice, jaw width 50mm, clamping width 34 mm

The dividing head of PROXXON. Ideal for the MF 70 and KT 70 microfrills.

For machining circular workpieces, producing radially offset holes and cutouts, milling of wrench flats, square edges, hexagonal edges, etc. Precise parting by vernier on the base body.

Chuck with reversible jaws: Clamping range inside 1.5 to 32 outside 12 to 65 mm. Recess for chuck 11 mm (for working longer shafts in vertical position). With mounting holes for horizontal and vertical mounting as well as suitable slot nuts and mounting screws for mounting on the MF 70 MICRO router and the KT 70 MICRO coordinate table. Supplied in a wooden box with sliding cover.

Precise dividing by nonius on the base body

11 mm recess for chuck

With mounting holes and screws

Internal clamping range: 1.5 to 32 mm

Clamping range outside: 12 to 65 mm

Size: 72 x 64 x 38 mm

Precision machine vice PM 40 from PROXXON.

Absolutely angled. Also hang laterally and frontally. With matching slot nuts and fastening screws for T-slots to MICROMOT standard (12 x 6 x 5 mm).

Particularly suitable for filigree and exact work with the MICRO Milling Machine MF 70 or the MICRO coordinate table KT 70. Packed in a wooden box with sliding lid.

Milled steel. Jaw width 46 mm, wingspan 30 mm. With matching sliding blocks and fixing screws.

Special features

Especially suitable for PROXXON MICRO Milling Machine MF 70 and PROXXON MICRO coordinate table.

The MICROMOT step clamps made of steel by PROXXON.

Complete with 2 step blocks and clamps, threaded bolts, nuts and T-slot nuts for the MICROMOT standard.

made of high quality steel

Further information

Suitable for MICROMOT milling and turning systems.

Vice, jaw width 50mm, clamping width 34 mm

The dividing head of PROXXON. Ideal for the MF 70 and KT 70 microfrills.

For machining circular workpieces, producing radially offset holes and cutouts, milling of wrench flats, square edges, hexagonal edges, etc. Precise parting by vernier on the base body.

Chuck with reversible jaws: Clamping range inside 1.5 to 32 outside 12 to 65 mm. Recess for chuck 11 mm (for working longer shafts in vertical position). With mounting holes for horizontal and vertical mounting as well as suitable slot nuts and mounting screws for mounting on the MF 70 MICRO router and the KT 70 MICRO coordinate table. Supplied in a wooden box with sliding cover.

Precise dividing by nonius on the base body

11 mm recess for chuck

With mounting holes and screws

Internal clamping range: 1.5 to 32 mm

Clamping range outside: 12 to 65 mm

Size: 72 x 64 x 38 mm

Precision machine vice PM 40 from PROXXON.

Absolutely angled. Also hang laterally and frontally. With matching slot nuts and fastening screws for T-slots to MICROMOT standard (12 x 6 x 5 mm).

Particularly suitable for filigree and exact work with the MICRO Milling Machine MF 70 or the MICRO coordinate table KT 70. Packed in a wooden box with sliding lid.

Milled steel. Jaw width 46 mm, wingspan 30 mm. With matching sliding blocks and fixing screws.

Special features

Especially suitable for PROXXON MICRO Milling Machine MF 70 and PROXXON MICRO coordinate table.

The MICROMOT step clamps made of steel by PROXXON.

Complete with 2 step blocks and clamps, threaded bolts, nuts and T-slot nuts for the MICROMOT standard.

made of high quality steel

Further information

Suitable for MICROMOT milling and turning systems.

Vice, jaw width 50mm, clamping width 34 mm

The dividing head of PROXXON. Ideal for the MF 70 and KT 70 microfrills.

For machining circular workpieces, producing radially offset holes and cutouts, milling of wrench flats, square edges, hexagonal edges, etc. Precise parting by vernier on the base body.

Chuck with reversible jaws: Clamping range inside 1.5 to 32 outside 12 to 65 mm. Recess for chuck 11 mm (for working longer shafts in vertical position). With mounting holes for horizontal and vertical mounting as well as suitable slot nuts and mounting screws for mounting on the MF 70 MICRO router and the KT 70 MICRO coordinate table. Supplied in a wooden box with sliding cover.

Precise dividing by nonius on the base body

11 mm recess for chuck

With mounting holes and screws

Internal clamping range: 1.5 to 32 mm

Clamping range outside: 12 to 65 mm

Size: 72 x 64 x 38 mm

Precision machine vice PM 40 from PROXXON.

Absolutely angled. Also hang laterally and frontally. With matching slot nuts and fastening screws for T-slots to MICROMOT standard (12 x 6 x 5 mm).

Particularly suitable for filigree and exact work with the MICRO Milling Machine MF 70 or the MICRO coordinate table KT 70. Packed in a wooden box with sliding lid.

Milled steel. Jaw width 46 mm, wingspan 30 mm. With matching sliding blocks and fixing screws.

Special features

Especially suitable for PROXXON MICRO Milling Machine MF 70 and PROXXON MICRO coordinate table.

Product information "MICRO Milling Machine MF 70 PROXXON"

The MICRO Milling Machine MF 70 from PROXXON. Small but nice: the precise vertical milling machine for laboratories, opticians, jewelers, electronics and modelers.

For working with extremely small milling cutters. Stable machine base made of cast iron, vertical guide and XY stage made of high-strength aluminum (surface-compacted). Backlash-free, adjustable dovetail guide in all axes.

Outrigger housing made of die-cast aluminum, with 24-pole special motor (balanced). For vibration-free work at high speeds.

Tool holder with MICROMOT system collets (steel, hardened, 3-fold slotted); each with 1 piece 1.0 - 1.5 - 2.0 - 2.4 - 3.0 and 3.2 mm.

Table with 3 continuous T-slots (MICROMOT standard 12 x 6 x 5 mm). A sliding ruler facilitates the positioning of the cross slide. All handwheels with scale ring adjustable to 0 (1 turn = 1.0mm, 1 graduation = 0.05 mm).

The illustrated clamps are included, but not the workpieces.

Special features

Boom housing made of die-cast aluminum, with 24-pole, balanced special motor. Tool holder through 3-fold slotted, hardened steel collets (Ø 1.0 / 1.5 / 2.0 / 2.4 / 3.0 / 3.2 mm). Table with T-slots, sliding ruler. Handwheels with adjustable scale ring (1 scale = 0.05 mm).

Dimensions

Table 200 x 70 mm, travel 134 mm across, 46 mm lengthwise, 80 mm high. Total height 340 mm.

Additional information

Motor 220-240 V = / 100 W, spindle speeds 5,000-20,000 / min.

For working with extremely small milling cutters. Stable machine base made of cast iron, vertical guide and XY stage made of high-strength aluminum (surface-compacted). Backlash-free, adjustable dovetail guide in all axes.

Outrigger housing made of die-cast aluminum, with 24-pole special motor (balanced). For vibration-free work at high speeds.

Tool holder with MICROMOT system collets (steel, hardened, 3-fold slotted); each with 1 piece 1.0 - 1.5 - 2.0 - 2.4 - 3.0 and 3.2 mm.

Table with 3 continuous T-slots (MICROMOT standard 12 x 6 x 5 mm). A sliding ruler facilitates the positioning of the cross slide. All handwheels with scale ring adjustable to 0 (1 turn = 1.0mm, 1 graduation = 0.05 mm).

The illustrated clamps are included, but not the workpieces.

Special features

Boom housing made of die-cast aluminum, with 24-pole, balanced special motor. Tool holder through 3-fold slotted, hardened steel collets (Ø 1.0 / 1.5 / 2.0 / 2.4 / 3.0 / 3.2 mm). Table with T-slots, sliding ruler. Handwheels with adjustable scale ring (1 scale = 0.05 mm).

Dimensions

Table 200 x 70 mm, travel 134 mm across, 46 mm lengthwise, 80 mm high. Total height 340 mm.

Additional information

Motor 220-240 V = / 100 W, spindle speeds 5,000-20,000 / min.