- Tools/supplies

Spot welder PUK 5.1 with welding microscope SM5

Product number:

344379

Packaging Unit:

1

No longer available

| Article name: | Spot welder |

|---|---|

| Brand: | PUK |

| Gross weight grams: | 12000,00 |

| Magnification: | 10x |

| Manufacturer name: | PUK 5.1 with welding microscope |

| Volt/Hz: | 230/50 |

Manufacturer Informations

Name: Lampert Werktechnik GmbH

Street: Ettlebener Str. 27

City: 97440 Werneck

Country: DE

Email: mail@lampert.info

Phone: 09722-9459-0

0 of 0 reviews

Login

No reviews found. Be the first to share your insights.

Accessoires (required)

Argon 4.6 with C10 cylinder

Welding gas according to EN ISO 14175

for welding process WIG/MIG

Composition: Ar. 99.996% (technical quality)

Special characteristics:

- Quiet and stable arc

- High process safety

- No burn-off of alloying constituents

- Universally usable

Attention:

Delivery only ex works!

(For delivery to German islands, an island surcharge applies)

Pick-up at Flume Technik in Essen is not possible!

Accessoires (optional)

Dimensions Ø mm:

0.25

|

Material:

750/- Gelbgold

Welding wire on coil for spot welding.

Dimensions Ø mm:

0.25

|

Material:

585/- Gelbgold

Welding wire on coil for spot welding.

Dimensions Ø mm:

0.20

|

Material:

750/- Weißgold

Welding wire on coil for spot welding.

Dimensions Ø mm:

0.25

|

Material:

960/- Platin

Welding wire on coil for spot welding.

Dimensions Ø mm:

0.35

|

Material:

Silber 970

Welding wire on coil for spot welding.

Dimensions Ø mm:

0.30

|

Material:

Fine titanium

Welding wire on coil for spot welding.

Dimensions Ø mm:

0.40

|

Material:

Edelstahl

Welding wire on coil for spot welding.

T-connector for shutter connection for PUK optical unit + microscope

Dimensions Ø mm:

0.40

|

Material:

Palladium

Welding wire on coil for spot welding.

For each selected waveform and device setting, the welding process can alternatively be triggered with the optional footswitch. This can make difficult workpiece geometries easier. Users familiar with laser, can trigger welding "as usual".

Accessories for "frequent welders" sucks off fumes and dusts generated during welding and neutralises it by means of an activated carbon filter. The absorber is automatically controlled by the welding device so that suction operates only during the welding process.

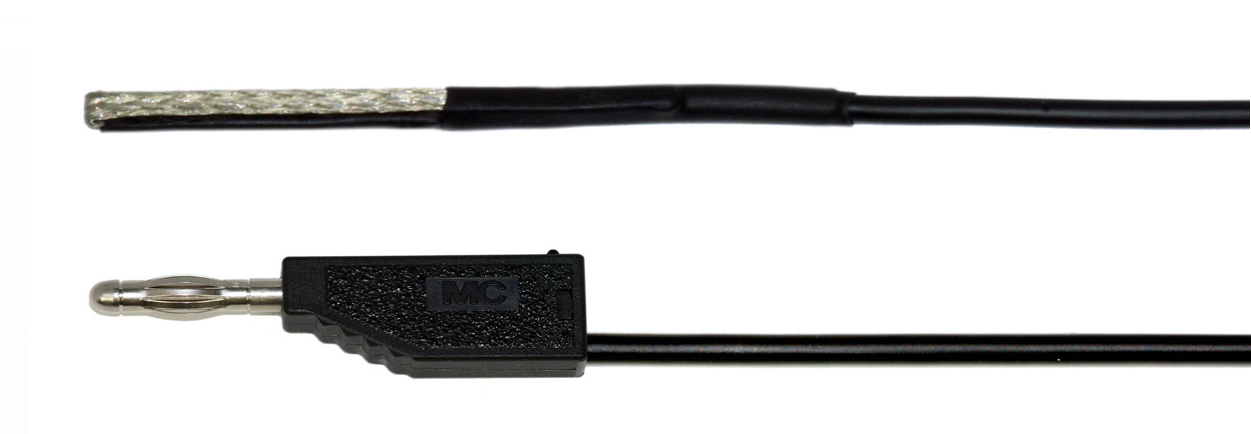

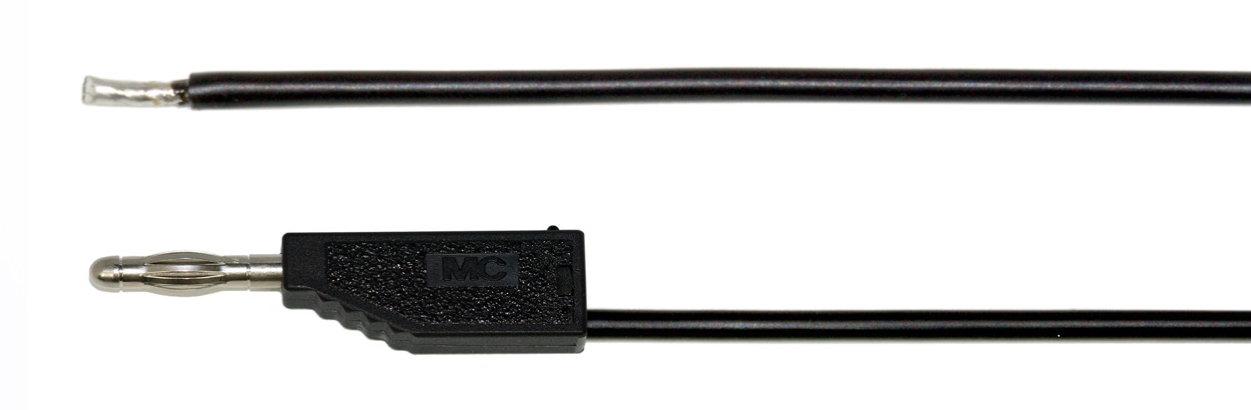

In spot welding, maintaining contact with workpieces is sometimes problematic. Tools can be combined safely with this contact band to achieve good electrical conductivity between the workpiece and the welding device.

In spot welding, maintaining contact with workpieces is sometimes problematic. Tools can be combined safely with this contact band to achieve good electrical conductivity between the workpiece and the welding device.

Using the tack welding set, loose parts can be quickly and easily fixed at a desired position in order to fully weld them in the next step.

The tack welding function thus is an aid for easy positioning, but not for final welding.

Preferred materials for this function are stainless steel and titanium.

Argon 4.6 Filling with C10 cylinder (in exchange for empty cylinder), including pick up from the customer

(The empty C10 bottle must be packed in a suitable box)

Welding gas according to EN ISO 14175

for welding process WIG/MIG

Composition: Ar. 99.996% (technical quality)

Special characteristics:

- Quiet and stable arc

- High process safety

- No burn-off of alloying constituents

- Universally usable

Attention:

Delivery only ex works!

(For delivery to German islands, an island surcharge applies)

Refilling at Flume Technik in Essen is not possible!

Please refer to the exchange cylinder overview for a listing of all cylinders that can be refilled.

Alternative for use of the included microscope. With connection to the PUK control unit via the control line on the unit for automatic darkening of the visual field during the ignition of the arc. Large visual field with 3 diopters magnification. Eye protection filter made of real glass. Glare-free magnifier. 230 V / 9 Watt Includes: - tripod arm for welding handpiece

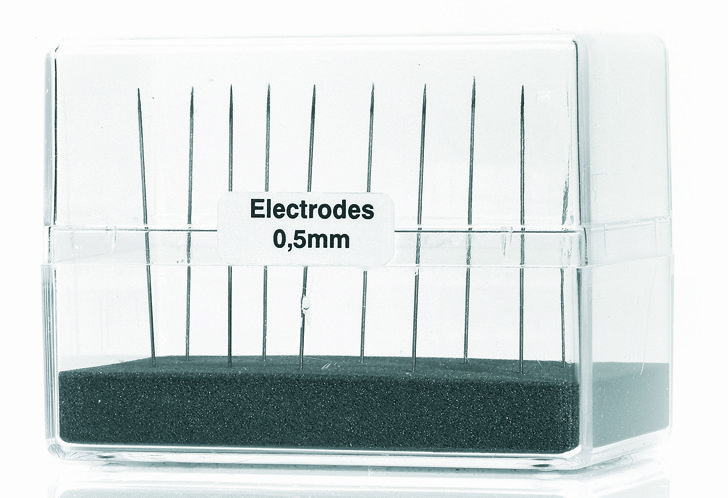

Article name:

Special electrodes

|

Special feature:

10 pieces 0,6 mm

Content: 10 pieces and 1 diamond grinding wheel 4891622

Substitutes

Tip

The new PUK 6 - fine welding technology that sets standards.

The comparison with its predecessors shows: 20 years of experience and passion in development raise fine welding technology to an unprecedented level with the PUK 6.

WELDING

• Up to 3.3 welds per second: up to 65 % faster weld spot sequence

• More homogeneous, smoother weld spots - Excellent weld seam even with variable weld spot spacing

• Higher heat input if required: Perfect results even with critical materials

• 50 % finer weld spots in the lower power spectrum

• Minimum pulse duration now down to 0.1 ms: 67 % shorter welding time in micro mode

HANDPIECE AND ELECTRODES

• 20 % faster and therefore more agile electrode stroke

• Maximum electrode thickness now up to 1 mm

• Up to 50 % longer electrode life*

OPERATION

• 70 % higher display resolution with increased viewing angle under all ambient conditions

• Faster operation and material selection through direct control with a central control element

• New standby mode: Continuous availability with 85 % lower energy consumption

WELDING MICROSCOPE SM6

• New elegant design

• Perfectly matched to the PUK 6

• Height and tilt adjustment for optimum working comfort and ergonomic working position

• Padded hand rests for comfortable working

• LED illumination on the microscope head, adjustable in 4 brightness levels, optimum illumination of the working area

• High precision at 10x magnification (optional 15x)

• Electronically controlled LCD eye protection module

• Can also be used as a fully-fledged viewing microscope

Scope of delivery:

PUK 6 fine welding unit with handpiece, welding microscope SM6, gas hose 3m, mains cable, contact clamp, diamond grinding wheel, 4x electrodes 0.8mm WLa, 2x electrodes 1.0mm WLa.

Product information "Spot welder PUK 5.1 with welding microscope SM5"

The new PUK 5.1 - the innovative fine welding technology. Developed by goldsmiths for goldsmiths.

NEW compared to predecessor model 5.0:

- MICRO-MODE - Microwelding: Welding materials with a thickness of less than 0.2 mm for wires and sheet metal in a more controlled manner extends the scope of PUK 5.1.

- Smoothing: Shorter repetition rates and bursts provide a continuous workflow. With this setting, you have the option of shaping the applied material as desired and greatly improving the welding properties of highly thermally conductive materials such as silver, copper and bronze.

- Advanced metal selection: Optimized welding parameters for copper and bronze. Despite high thermal conductivity of the PUK has this under control.

Fine welding technology - consistently refined. Microwelding where others stop.

Welding fixtures, applying metal, fixing, welding eyelets, sealing pores, producing seams, welding of precious metals incl. Silver, copper and bronze and all weldable alloys, material thicknesses below 0.2 mm are mastered by the new PUK. Even the supreme discipline, the manufacture and repair of prong settings with precious gemstones in the immediate vicinity of the welding process, mastered the PUK with flying colors.

COMPACT AND VERSATILE TIG IMPULSE FINE WELDING DEVICE

For all areas of application in the workshop, where precision, reliability and controllability are crucial - from the smallest repair to series production to extraordinary creations in jewelery production.

The PUK principle is the original - ingenious and unique:

Our know-how has been in the device for more than 17 years and has been developed consistently. As soon as the electrode tip of the handpiece touches the workpiece, the welding process starts automatically. The protective gas argon forms a protective gas atmosphere above the weld and prevents interfering influences from the outside. The power pulse, specially tailored to the welding task, ignites an arc and produces a controlled melting of the metal - as frequently and precisely as desired.

THE NEW LIGHTNING OF WELDING

With the PUK, the user is able to achieve perfect welding results in gold, silver, platinum, copper and bronze without in-depth knowledge of metallurgy. Even the processing of stainless steel, titanium and all weldable alloys are part of the range of services. The PUK takes control of the right welding parameters for perfect results.

Equipped with handpiece, gas hose 3 m, power cable, 1x contact clamp, brass brush, glass fiber insert, diamond grinding wheel, 1x electrode 0.6 mm INOSTAR, 6x electrodes 0.6 mm WLa.

Supplied with with welding microscope SM5.1, equipped with electronically controlled eye protection filter (DIN3 / DIN11), 10x magnification, LED lighting 3W, tilt adjustment, hand restraints, handpiece fixation, cable holder, spacer sleeve.

NEW compared to predecessor model 5.0:

- MICRO-MODE - Microwelding: Welding materials with a thickness of less than 0.2 mm for wires and sheet metal in a more controlled manner extends the scope of PUK 5.1.

- Smoothing: Shorter repetition rates and bursts provide a continuous workflow. With this setting, you have the option of shaping the applied material as desired and greatly improving the welding properties of highly thermally conductive materials such as silver, copper and bronze.

- Advanced metal selection: Optimized welding parameters for copper and bronze. Despite high thermal conductivity of the PUK has this under control.

Fine welding technology - consistently refined. Microwelding where others stop.

Welding fixtures, applying metal, fixing, welding eyelets, sealing pores, producing seams, welding of precious metals incl. Silver, copper and bronze and all weldable alloys, material thicknesses below 0.2 mm are mastered by the new PUK. Even the supreme discipline, the manufacture and repair of prong settings with precious gemstones in the immediate vicinity of the welding process, mastered the PUK with flying colors.

COMPACT AND VERSATILE TIG IMPULSE FINE WELDING DEVICE

For all areas of application in the workshop, where precision, reliability and controllability are crucial - from the smallest repair to series production to extraordinary creations in jewelery production.

The PUK principle is the original - ingenious and unique:

Our know-how has been in the device for more than 17 years and has been developed consistently. As soon as the electrode tip of the handpiece touches the workpiece, the welding process starts automatically. The protective gas argon forms a protective gas atmosphere above the weld and prevents interfering influences from the outside. The power pulse, specially tailored to the welding task, ignites an arc and produces a controlled melting of the metal - as frequently and precisely as desired.

THE NEW LIGHTNING OF WELDING

With the PUK, the user is able to achieve perfect welding results in gold, silver, platinum, copper and bronze without in-depth knowledge of metallurgy. Even the processing of stainless steel, titanium and all weldable alloys are part of the range of services. The PUK takes control of the right welding parameters for perfect results.

Equipped with handpiece, gas hose 3 m, power cable, 1x contact clamp, brass brush, glass fiber insert, diamond grinding wheel, 1x electrode 0.6 mm INOSTAR, 6x electrodes 0.6 mm WLa.

Supplied with with welding microscope SM5.1, equipped with electronically controlled eye protection filter (DIN3 / DIN11), 10x magnification, LED lighting 3W, tilt adjustment, hand restraints, handpiece fixation, cable holder, spacer sleeve.