-

Tools/supplies

-

Drilling, polishing, grinding

-

Turning

-

Facilities, compressed air and vacuum

-

Goldsmith special tools/GRS

-

Small tools

-

Soldering, melting, casting, welding

- Measuring and testing

-

Surface treatment

-

Clean, dry, turning, sawing

-

CAD-software / software

-

Watchmaker tools

-

Sales and workshop tools

-

3D Werkzeuge & Reinigung

-

Drilling, polishing, grinding

slide 2 of 6

slide 1 to 5 of 6

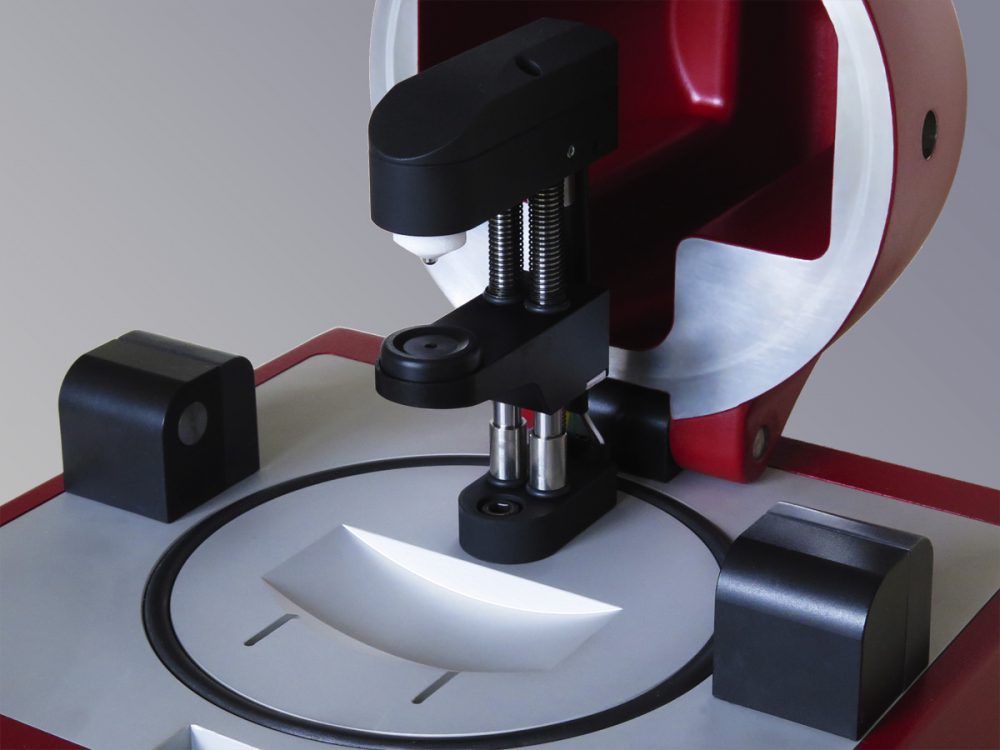

WATER-RESISTANCE TESTER SM-8850/ 20 bar

Product number:

344941

Packaging Unit:

1

the delivery time is approx. 2 more weeks.

Downloads

| Article name: | WATER-RESISTANCE TESTER SM-8850/ 20 bar |

|---|---|

| Brand: | Sigma |

| Dimensions height mm: | 220,00 |

| Dimensions width mm: | 310,00 |

| External dimension length: | 210,00 |

| Gross weight grams: | 7400,00 |

| Readability: | -0,75 up to 20 bar |

Manufacturer Informations

Name: Rudolf Flume Technik GmbH

Street: Hachestr. 66

City: 45127 Essen

Country: DE

Email: info@flume.de

Phone: 0049-201-18990

0 of 0 reviews

Login

No reviews found. Be the first to share your insights.

Accessoires (required)

slide 1 to 2 of 2

The Sigma Booster SM 9700-38 increases the existing compressed air 3.5 times. It is required for the water leak tester SM 8850-30 if tests are to be carried out at up to 30 bar. Technical Specifications: Pressure increase: 3.5x Max. output pressure: 30 bar Min. output pressure: 9.5 bar A boiler compressor of min. 8 bar is required Includes: Pressure hose Couplings Control cable

Performance:

44 l/min

Oil-lubricated compressors, almost noise-free (whisper quiet), max. 40 to 55 dB (at 1 m distance), user-friendly, minimum maintenance, corrosion protection in the boiler, handy and easy to carry. Air suction capacity 50 L/min Air delivery capacity 32 l/min The compressors are built as a complete air compressor unit and are equipped with heat switch-off, water separator, adjustable pressure regulator, quick coupling, safety valve, pressure gauge on the boiler and manually adjustable shut-off valve for condensate draining. br 230 V / 50 Hz, 340 Watt.

Accessoires (optional)

slide 1 to 2 of 2

Product information "WATER-RESISTANCE TESTER SM-8850/ 20 bar"

Since its first issue, the Water-Resistance Tester SM-8850 series has undergone continuous improvements and enhancements. With its state-of-the-art advanced technology, the latest version includes important new features and functionality. Similar in user-friendliness as its worldwide recognized and adopted predecessor, the SM-8850 comes with a meaningful increase in performanceamong many other advantages.

The SM-8850 series instrument allows testing watches at pressures ranging from -0.75 to 10 bar for the SM-8850/10, respectively to 20 bar for the SM-8850/20, 30 bar for the SM-8850/30 and 50 bar for the SM-8850/50.

This series of test instruments is optimized for very high pressure testing. A new front locking system with safeguard, along with a redesigned compact side lock for the high pressure versions ensures a safer operation of the device.

The new pressuring chamber is designed to withstand pressures in excess of 100 bar and to cater for very big sized watch-cases and even diving watches of a thickness of up to 35 mm, a width of 65 to 79 mm and a length of 78 to 104 mm. This increase in test object size was created without increasing the internal chamber volume: with less than 0.5 litre of volume, the pressuring chamber features a reduction of more than 15% compared to its predecessor, and more than 60% compared to other market products, allowing for shorter test cycles and lesser air consumption, particularly for high pressure tests.

The newly designed sensor head is made out of a special metal alloy to achieve ultra-stable and unmatched performance; even extremely stiff watch-cases can be reliably tested at very low pressure.

Combined with a new, fast and very high-precision 18 bits data acquisition system, the state-of-the-art electronic circuit board complies with the latest and strongest CE regulation (European regulation) and features an environmental friendly lead free design (RoHS conform).

The SM-8850 series instrument allows testing watches at pressures ranging from -0.75 to 10 bar for the SM-8850/10, respectively to 20 bar for the SM-8850/20, 30 bar for the SM-8850/30 and 50 bar for the SM-8850/50.

This series of test instruments is optimized for very high pressure testing. A new front locking system with safeguard, along with a redesigned compact side lock for the high pressure versions ensures a safer operation of the device.

The new pressuring chamber is designed to withstand pressures in excess of 100 bar and to cater for very big sized watch-cases and even diving watches of a thickness of up to 35 mm, a width of 65 to 79 mm and a length of 78 to 104 mm. This increase in test object size was created without increasing the internal chamber volume: with less than 0.5 litre of volume, the pressuring chamber features a reduction of more than 15% compared to its predecessor, and more than 60% compared to other market products, allowing for shorter test cycles and lesser air consumption, particularly for high pressure tests.

The newly designed sensor head is made out of a special metal alloy to achieve ultra-stable and unmatched performance; even extremely stiff watch-cases can be reliably tested at very low pressure.

Combined with a new, fast and very high-precision 18 bits data acquisition system, the state-of-the-art electronic circuit board complies with the latest and strongest CE regulation (European regulation) and features an environmental friendly lead free design (RoHS conform).