-

Tools/supplies

-

Drilling, polishing, grinding

-

Turning

-

Facilities, compressed air and vacuum

-

Goldsmith special tools/GRS

-

Small tools

-

Soldering, melting, casting, welding

-

Pickling

-

Casting

-

Soldering

- Soldering equipment

-

Accessories/spare parts

-

Soldering and melting burner

-

Gas saving equipment

-

Blow torches

-

Soft soldering (Tin)

-

Soldering vapour absorber

-

Soldering bolt/soldering aid

-

Holding tools for soldering

-

Soldering materials

-

Chemicals for the hard solder

-

Chemicals for soft soldering

-

Gas installation

-

Solder and materials

-

Melt

-

Welding

-

Vulcanizing

-

Grow

-

Pickling

-

Measuring and testing

-

Surface treatment

-

Clean, dry, turning, sawing

-

CAD-software / software

-

Watchmaker tools

-

Sales and workshop tools

-

Drilling, polishing, grinding

Soldering dev. Microflame 240

Product number:

249060

Packaging Unit:

1

Extra order! Delivery time on request, return is not possible.

| Application: | 0.5 - 1.5 mm |

|---|---|

| Article name: | Soldering dev. Microflame 240 |

| Brand: | MIG-O-MAT |

| Dimensions height mm: | 515,00 |

| Dimensions width mm: | 375,00 |

| External dimension length: | 515,00 |

| Gross weight grams: | 55.000 |

| Performance: | 240 l/h |

| Volt/Hz: | 230 / 50 |

| Watt: | 1700 |

Manufacturer Informations

Name: MIG·O·MAT Mikrofügetechnik GmbH

Street: Werkstr. 20

City: 57299 Burbach

Country: DE

Email: info@mig-o-mat.com

Phone: + 49 (0) 2736 4154 0

0 of 0 reviews

Login

No reviews found. Be the first to share your insights.

Accessoires (required)

Article name:

Soldering dev. Microflame 240

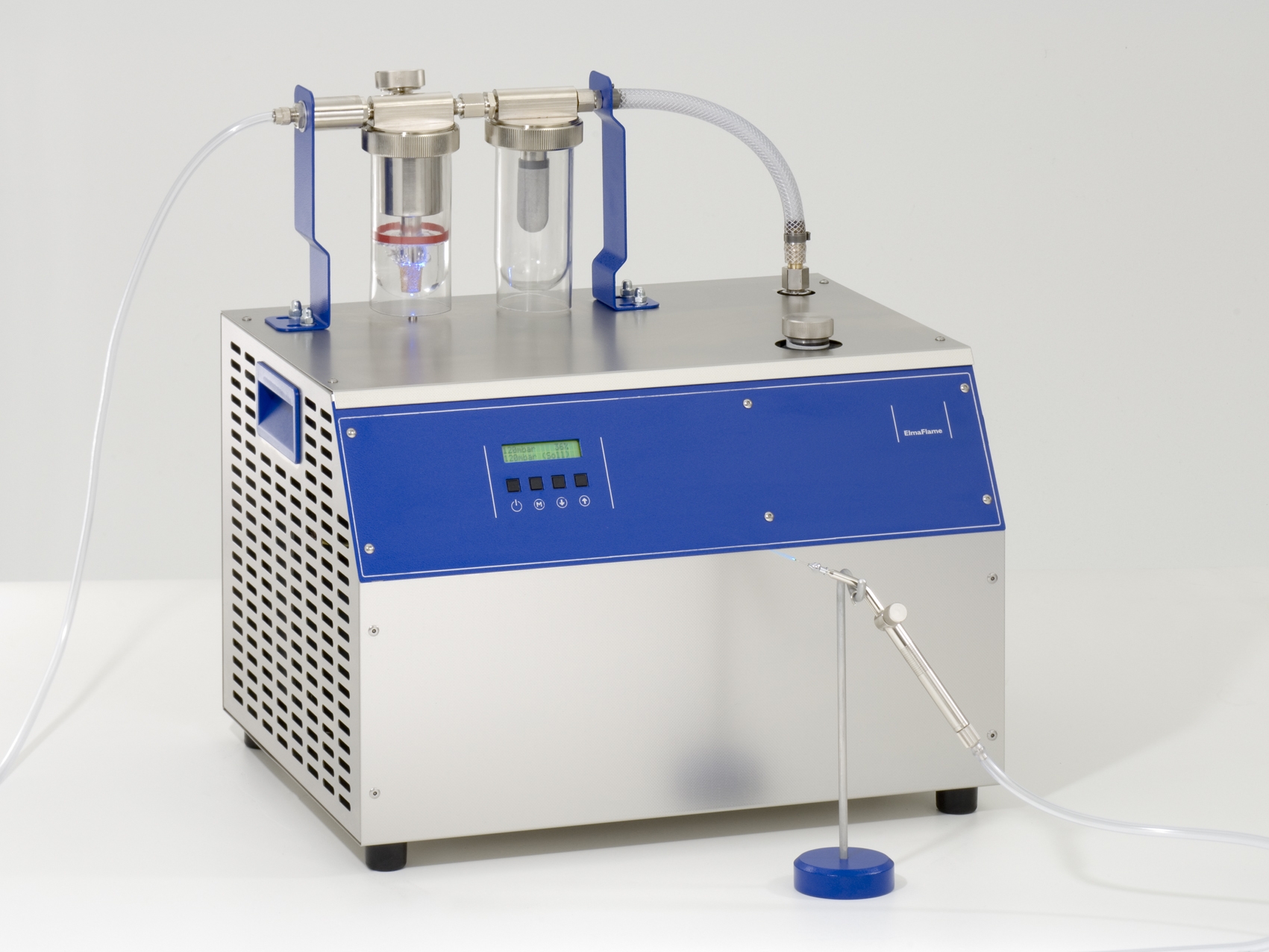

For fine, small, and large soldering work in the goldsmith's and watchmaker's workshop.

Technical Specifications:

- For 1-5 workstations

- Reactor contents 4.4 litre electrolyte

- Gas pressure shown on the display (variable input of the target pressure)

- Even when using multiple burner handpieces, the flame size will remain constant due to the automatic pressure control.

- Whisper-quiet cooling: very low cooling air noise (temperature-controlled in partial load range).

- Tightness test can be carried out automatically upon start of operation.

- Gas purification/condensate separation without consumables.

- Complies with safety requirements according to the accident prevention regulations BGR500 and DIN 32508.

- Working pressure monitor

- Safety pressure monitor

- Flame arrestor

- Thermally controlled gas after flow protection

- 2 glass containers for condensate and methanol for easy monitoring of fill level and refilling

- Temperature monitoring of the cooling function

- LCD display (e.g., for leak testing, error messages, etc.)

Accessories for 1 workstation included:

1 burner handpiece with fine control valve br

1 burner stand as pictured br

5 burner nozzles, assorted

3 meters of gas hose

1 fill level float for electrolyte fluid

1 feed hopper

1 bottle of Redux, 1 litre

1 electrolyte filling

230 V / 50-60 Hz, 1700 Watt

Accessoires (optional)

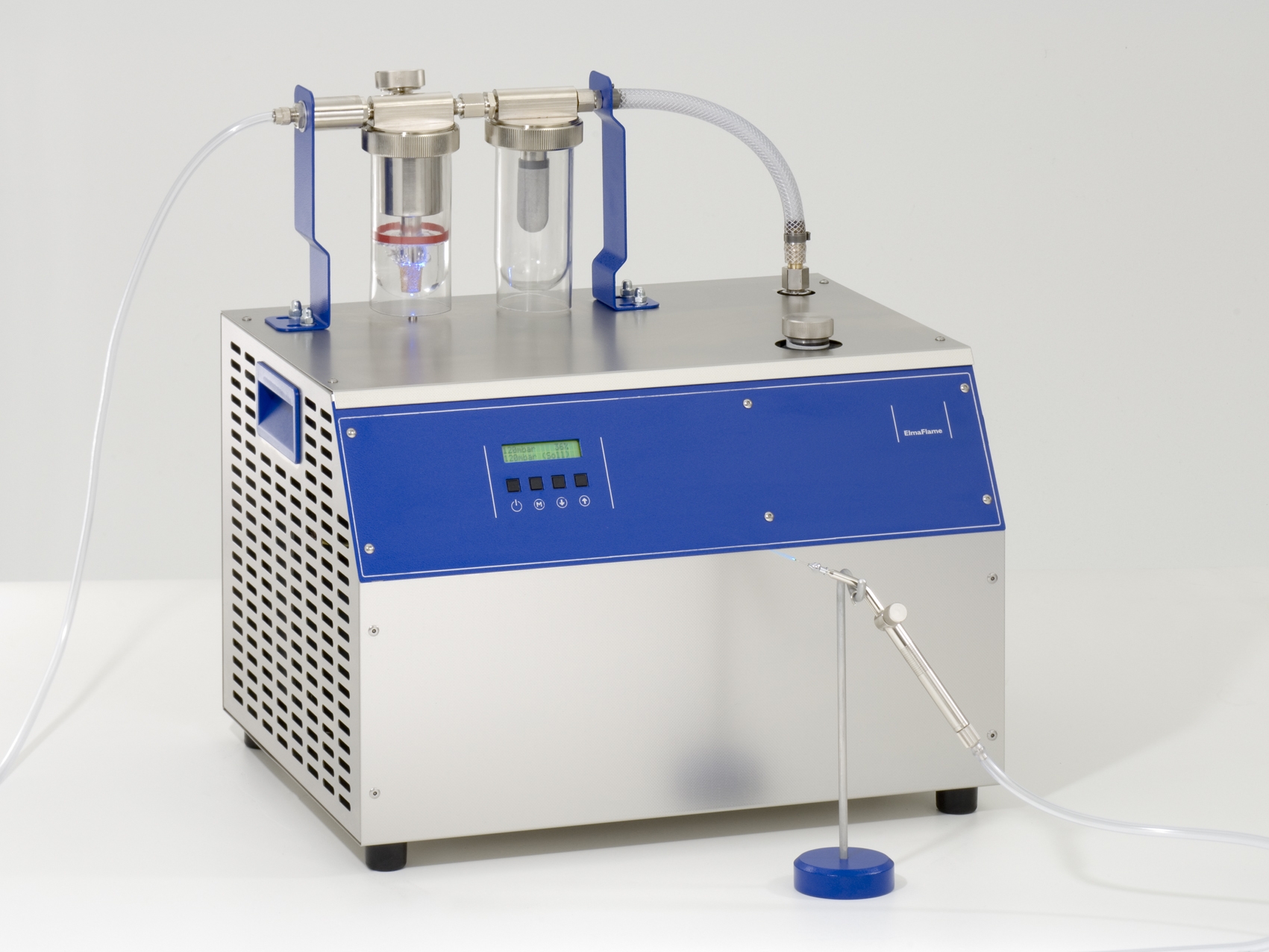

For all Elmaflame and Lötstar devices (except Lötstar 80). Only available in conjunction with device order.

For platinum processing without evaporatorfluid/flux, an additional Gas output with flame arrestor, temperature-sensitive gas cut-off valve, micro burner, and 3 m hose are installed. (only sold with device)

Includes: 1 burner handpiece 3 m of gas hose 1 soldering stand 1 tee 5 nozzles, assorted

Brand:

MIG-O-MAT

|

Manufacturer name:

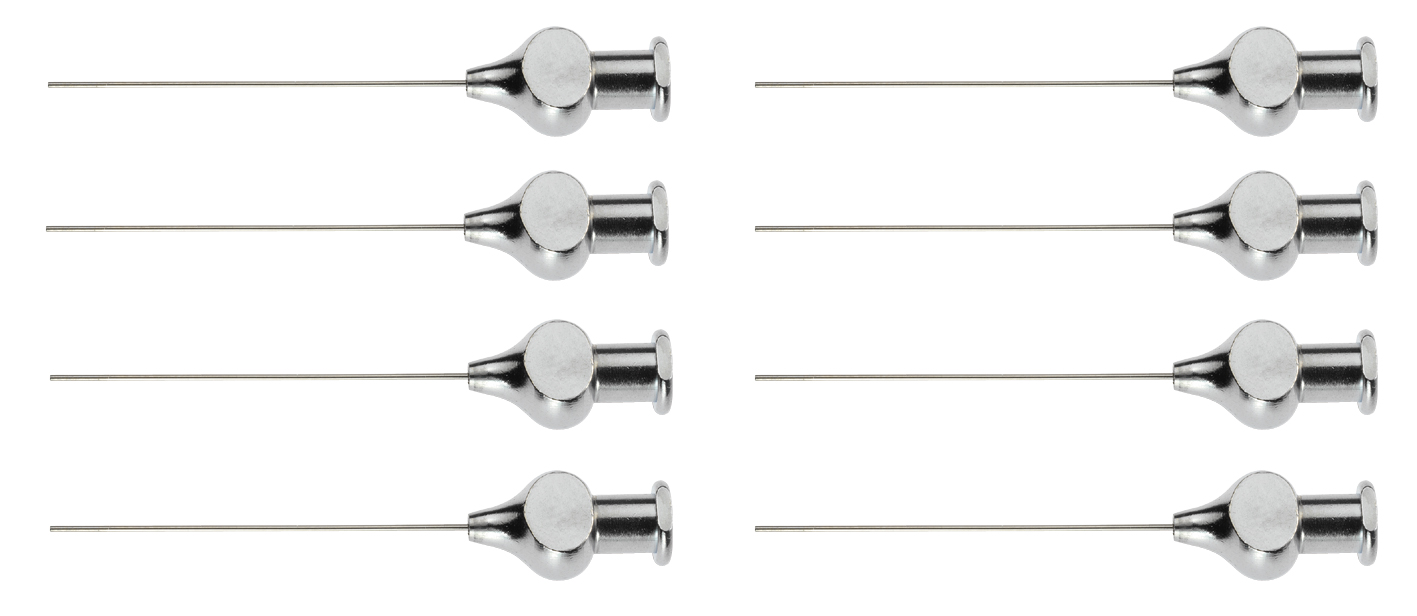

No. 26

For handpiece attachment 0.30 - 0.34 mm.

Replacements

Brand:

MIG-O-MAT

|

Manufacturer name:

No. 26

For handpiece attachment 0.30 - 0.34 mm.

Brand:

MIG-O-MAT

|

Manufacturer name:

No. 23

For handpiece attachment 0.30 - 0.34 mm.

Brand:

MIG-O-MAT

|

Manufacturer name:

No. 22

For handpiece attachment 0.30 - 0.34 mm.

Brand:

MIG-O-MAT

|

Manufacturer name:

No. 21

For handpiece attachment 0.30 - 0.34 mm.

Brand:

MIG-O-MAT

|

Manufacturer name:

No. 20

For handpiece attachment 0.30 - 0.34 mm.

Brand:

MIG-O-MAT

|

Manufacturer name:

No. 19

For handpiece attachment 0.30 - 0.34 mm.

Brand:

MIG-O-MAT

|

Manufacturer name:

No. 18

For handpiece attachment 0.30 - 0.34 mm.

Glass container for condensate, dia. 52 mm, for Elmaflame/MIG-O-MAT

Rebound protection for Elmaflame/MIG-O-MAT

Gas hose MIG-O-MAT/Elmaflame (by the metre)

Can be used as an alternative to methanol for MIG-O-MAT devices. Unlike methanol, this liquid is non-toxic and does not need to be shipped as hazardous goods in small quantities.

The flame temperature is limited to 1800 °C by the evaporator liquid. The flame colour is blue.

Do not use in conjunction with flux.

Product information "Soldering dev. Microflame 240"

For fine, small, and large soldering work in the goldsmith's and watchmaker's workshop.

Technical Specifications:

- For 1-5 workstations

- Reactor contents 4.4 litre electrolyte

- Gas pressure shown on the display (variable input of the target pressure)

- Even when using multiple burner handpieces, the flame size will remain constant due to the automatic pressure control.

- Whisper-quiet cooling: very low cooling air noise (temperature-controlled in partial load range).

- Tightness test can be carried out automatically upon start of operation.

- Gas purification/condensate separation without consumables.

- Complies with safety requirements according to the accident prevention regulations BGR500 and DIN 32508.

- Working pressure monitor

- Safety pressure monitor

- Flame arrestor

- Thermally controlled gas after flow protection

- 2 glass containers for condensate and methanol for easy monitoring of fill level and refilling

- Temperature monitoring of the cooling function

- LCD display (e.g., for leak testing, error messages, etc.)

Accessories for 1 workstation included:

1 burner handpiece with fine control valve br

1 burner stand as pictured br

5 burner nozzles, assorted

3 meters of gas hose

1 fill level float for electrolyte fluid

1 feed hopper

1 bottle of Redux, 1 litre

1 electrolyte filling

230 V / 50-60 Hz, 1700 Watt

Technical Specifications:

- For 1-5 workstations

- Reactor contents 4.4 litre electrolyte

- Gas pressure shown on the display (variable input of the target pressure)

- Even when using multiple burner handpieces, the flame size will remain constant due to the automatic pressure control.

- Whisper-quiet cooling: very low cooling air noise (temperature-controlled in partial load range).

- Tightness test can be carried out automatically upon start of operation.

- Gas purification/condensate separation without consumables.

- Complies with safety requirements according to the accident prevention regulations BGR500 and DIN 32508.

- Working pressure monitor

- Safety pressure monitor

- Flame arrestor

- Thermally controlled gas after flow protection

- 2 glass containers for condensate and methanol for easy monitoring of fill level and refilling

- Temperature monitoring of the cooling function

- LCD display (e.g., for leak testing, error messages, etc.)

Accessories for 1 workstation included:

1 burner handpiece with fine control valve br

1 burner stand as pictured br

5 burner nozzles, assorted

3 meters of gas hose

1 fill level float for electrolyte fluid

1 feed hopper

1 bottle of Redux, 1 litre

1 electrolyte filling

230 V / 50-60 Hz, 1700 Watt