-

Tools/supplies

-

Drilling, polishing, grinding

-

Turning

-

Facilities, compressed air and vacuum

-

Goldsmith special tools/GRS

-

Small tools

-

Soldering, melting, casting, welding

-

Measuring and testing

-

Surface treatment

-

Files

-

Electroplate

-

Electroplating equipment

-

Accessories for all galvanic devices

-

Accessories for equipment container

-

Accessories for RM01

-

Anodes

-

Stiftgalvanik

-

Stiftgalvanik chemicals

-

Stiftgalvanik accessories

-

Galvanic degreasing

-

Chemicals for the preparation

-

Chemicals for electroplating power

-

Chemicals to the plating without current

-

Chemicals to shine (material ablation)

-

Blacking for silver

-

Surface protection

-

Electroplating equipment

-

Engraving

-

Plating

-

Coatings

-

Sand blasting

-

Files

-

Clean, dry, turning, sawing

-

CAD-software / software

-

Watchmaker tools

-

Sales and workshop tools

-

Drilling, polishing, grinding

Silver gloss bath for electrolytic glossing (material removal)

Product number:

4637076

Packaging Unit:

1

From Stock

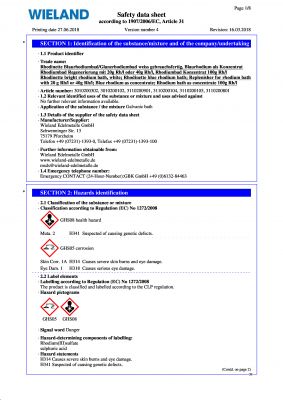

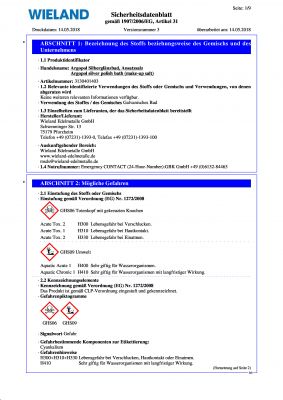

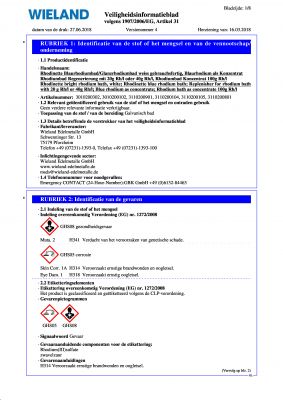

Dangerous goods information

| Description | KALIUMCYANID, FEST, GEMISCH |

|---|---|

| Dangerous goods from: | 1 |

| Dangerous goods class: | 6.1 |

| UN-Nummer: | 1680 |

| Dangerous goods information: |

| Article name: | Silberglänzbad |

|---|---|

| Brand: | Wieland |

| Content: | 1,00 |

| Dangerous goods from quantity: | 1 |

| Manufacturer name: | Argopol |

| Temperature °C.: | 45-70 °C |

| Time: | 10 - 60 Sek. |

| Unit content: | Liter |

| Volt/Hz: | 8 - 25 V |

Manufacturer Informations

Name: Wieland Edelmetalle +

Street: Schwenninger Str. 13

City: 75179 Pforzheim

Country: DE

Email: info@wieland-edelmetalle.de

Phone: +49 72 31/13 93 – 0

0 of 0 reviews

Login

No reviews found. Be the first to share your insights.

Product information "Silver gloss bath for electrolytic glossing (material removal)"

Contains cyanide. Requires polishing unit, e.g. Wilaplat 500 and tray support WT 3 HR. When glossing the surface of the jewel is removed uniformly.

Work instructions: electroplate two stainless steel anodes in a PPH tub at a temperature of 60-80 °C and a current of 10-100 A for 10 to 60 sec.

Work instructions: electroplate two stainless steel anodes in a PPH tub at a temperature of 60-80 °C and a current of 10-100 A for 10 to 60 sec.