-

Tools/supplies

-

Drilling, polishing, grinding

-

Turning

-

Facilities, compressed air and vacuum

-

Goldsmith special tools/GRS

-

Small tools

-

Soldering, melting, casting, welding

-

Measuring and testing

-

Surface treatment

-

Clean, dry, turning, sawing

-

CAD-software / software

-

Watchmaker tools

-

Castles from

-

Band service

-

Insertion apparatus

-

Mainspring

-

Case opener and-closer

-

Glass service

- Oil, oils, fats

-

Driving and rivets

-

Movement holder for small watches

-

Cone roller burnishing equipment

-

Hand tools

-

Tool kit for the watch service

-

Tool assortments

-

Other small clock tools

-

Other large clock tools

-

Spezialwerkzeuge für Rolex

-

Zifferblatt Fräsvorrichtung

-

Castles from

-

Sales and workshop tools

-

3D Werkzeuge & Reinigung

-

Drilling, polishing, grinding

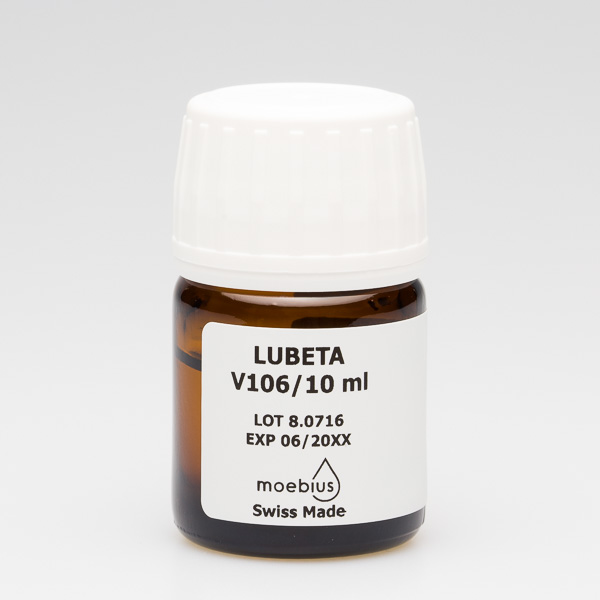

ETA immersion lubrication solution Lubeta V106, 10ml

Product number:

352879

Packaging Unit:

1

From Stock

Dangerous goods information

| Description | Kohlenwasserstoffe flüssig n.a.g.Hydrocarbons,Liqiid N.O.S. |

|---|---|

| Dangerous goods from: | 2800 |

| Dangerous goods class: | 3 |

| UN-Nummer: | 3295 |

| Dangerous goods information: |

Downloads

| Application: | Rotor bearing |

|---|---|

| Article name: | Dip lubrication solution ETA V106 |

| Brand: | Moebius |

| Content: | 10,00 |

| Dangerous goods from quantity: | 2800 |

| Manufacturer name: | V106 |

| Unit content: | ml |

Manufacturer Informations

Name: Rudolf Flume Technik GmbH

Street: Hachestr. 66

City: 45127 Essen

Country: DE

Email: info@flume.de

Phone: 0049-201-18990

0 of 0 reviews

Login

No reviews found. Be the first to share your insights.

Accessoires (optional)

slide 1 of 1

Glass.

for application of epilamisation agents.

Product information "ETA immersion lubrication solution Lubeta V106, 10ml"

Ready-to-use lubricating solution for diving, developed by the ETA for special areas of application / movement components after cleaning mechanical movements.

Ready-to-use solution for splash lubrication. It enables the homogeneous deposition of a thin film of lubricant. This product is specially recommended for the lubrication of ball bearings and springs. Ideal for customer service.

USE:

First clean the wheel with the cleaning machine, then immerse the cleaned wheel in the immersion lubricant V105 for approx. 10 seconds.

After this process, remove any excess solution using a blow gun or a dust blower.

Then lay the wheel to dry on a metallic surface for approx. 15 minutes.

Application: ball bearings for automatic rotors

Ready-to-use solution for splash lubrication. It enables the homogeneous deposition of a thin film of lubricant. This product is specially recommended for the lubrication of ball bearings and springs. Ideal for customer service.

USE:

First clean the wheel with the cleaning machine, then immerse the cleaned wheel in the immersion lubricant V105 for approx. 10 seconds.

After this process, remove any excess solution using a blow gun or a dust blower.

Then lay the wheel to dry on a metallic surface for approx. 15 minutes.

Application: ball bearings for automatic rotors