-

Tools/supplies

-

Drilling, polishing, grinding

-

Turning

-

Facilities, compressed air and vacuum

-

Goldsmith special tools/GRS

-

Small tools

-

Soldering, melting, casting, welding

-

Measuring and testing

-

Surface treatment

-

Files

-

Electroplate

- Electroplating equipment

-

Accessories for all galvanic devices

-

Accessories for equipment container

-

Accessories for RM01

-

Anodes

-

Stiftgalvanik

-

Stiftgalvanik chemicals

-

Stiftgalvanik accessories

-

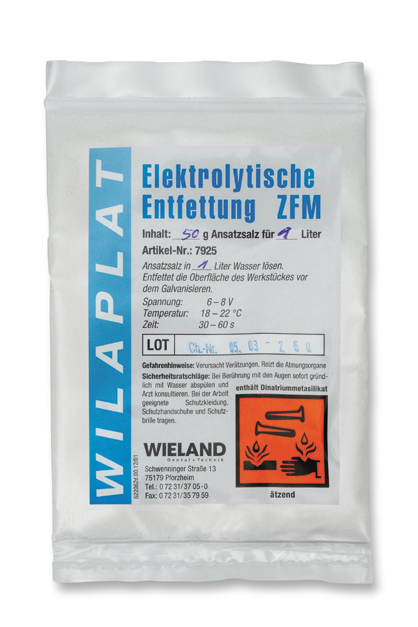

Galvanic degreasing

-

Chemicals for the preparation

-

Chemicals for electroplating power

-

Chemicals to the plating without current

-

Chemicals to shine (material ablation)

-

Blacking for silver

-

Surface protection

-

Engraving

-

Plating

-

Coatings

-

Sand blasting

-

Files

-

Clean, dry, turning, sawing

-

CAD-software / software

-

Watchmaker tools

-

Sales and workshop tools

-

Drilling, polishing, grinding

Galvanising unit KGA 2000

Product number:

202544

Packaging Unit:

1

From Stock

| Article name: | Galvanising unit KGA 2000 |

|---|---|

| Brand: | Jentner |

| Dimensions height mm: | 260 |

| Dimensions width mm: | 330 |

| External dimension length: | 480 |

| Gross weight grams: | 15500,00 |

| Volt/Hz: | 230 / 50 |

| Watt: | 400 |

Manufacturer Informations

Name: Jentner

Street: Johann-Staib-Str. 2

City: 75179 Pforzheim

Country: DE

Email: info@jentner.de

Phone: 07231-418094-0

0 of 0 reviews

Login

No reviews found. Be the first to share your insights.

Accessoires (required)

With clamping device for article rods, with two interchangeable wires.

Temperature-resistant up to 80 °C. Capacity 1.5 litres.

Temperature-resistant up to 80 °C. Capacity: 3 litres

Accessoires (optional)

Colour:

Pale yellow 14 ct.

Use at room temperature, heating as for conventional electrolytes is not required. Low repair and maintenance costs since neither immersion heater nor thermostat or circulation is required.

Energy-efficient

Ready to use. Includes 1 g fine gold, contains cyanide.

To create decorative, thin but hard colour gilding on all non-ferrous and precious metal alloys

Contents 1 litres

Application

Anodes - stainless steel

Tray: glass or plastic

Goods movement: no

Temperature: 18-25 °C

Voltage: 3V

Time: 10-30 seconds

Colour:

Red

Use at room temperature, heating as for conventional electrolytes is not required. Low repair and maintenance costs since neither immersion heater nor thermostat or circulation is required.

Energy-efficient

Ready to use. Includes 1 g fine gold, contains cyanide.

To create decorative, thin but hard colour gilding on all non-ferrous and precious metal alloys

Contents 1 litres

Application

Anodes - stainless steel

Tray: glass or plastic

Goods movement: no

Temperature: 18-25 °C

Voltage: 3V

Time: 10-30 seconds

Colour:

Yellow 18 ct.

Use at room temperature, heating as for conventional electrolytes is not required. Low repair and maintenance costs since neither immersion heater nor thermostat or circulation is required.

Energy-efficient

Ready to use. Includes 1 g fine gold, contains cyanide.

To create decorative, thin but hard colour gilding on all non-ferrous and precious metal alloys

Contents 1 litres

Application

Anodes - stainless steel

Tray: glass or plastic

Goods movement: no

Temperature: 18-25 °C

Voltage: 3V

Time: 10-30 seconds

Colour:

rosegold

Use at room temperature, heating as for conventional electrolytes is not required. Low repair and maintenance costs since neither immersion heater nor thermostat or circulation is required.

Energy-efficient

Ready to use. Includes 1 g fine gold, contains cyanide.

To create decorative, thin but hard colour gilding on all non-ferrous and precious metal alloys

Contents 1 litres

Application

Anodes - stainless steel

Tray: glass or plastic

Goods movement: no

Temperature: 18-25 °C

Voltage: 3V

Time: 10-30 seconds

(Ready to use). With 36 g of fine silver per litre. Contains cyanide. Achieves high-gloss silver layers.

Application:

Anodes - fine silver

Tray - Glass/PPH

Goods movement - yes

Temperature - 20-25 °C

Voltage - 0.5-1.2 V

Time - 5-50 min.

Preparation salt, cyanide, 60-90 g per litre. For all articles for degreasing before electroplating treatment.

Application:

Anodes - stainless steel

Tray - glass/PPH

Goods movement - no

Temperature - 15-30 °C

Voltage - 8-10 V

Time - 30-60 sec.

Concentrate with 2 g of rhodium per litre.

The products achieve dark, anthracite rhodium plating and are extremely resistant to abrasion.

Application:

Anodes - titanium/mixed oxide

Tray - Glass/PPH

Goods movement - yes

Temperature - 18-25 °C

Voltage - 1.8-2.2 V

Time - 1-2 minutes

Article name:

Ruthenium bath JE 12

Ready to use. Includes 5 g ruthenium.

The products obtain a dark, grey-black surface. The bath preserves lasting shine.

Application:

Anodes - titanium or mixed oxide

Tray - PPH

Goods movement - yes

Temperature - 60-70 °C

Voltage - 2-3 V

Time - 2-4 minutes

Article name:

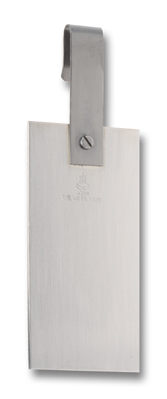

Stainless steel V2A anode

For degreasing and colour gilding baths.

Article name:

Titanium anode

For rhodium plating, adhesion gold plating, gold plating, as well as all acidic precious metal baths.

Article name:

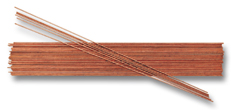

Fine silver anode

For matt and gloss silver baths.

Article name:

Copper anode

For cyanide copper baths.

For connection to a thermostat or an electrical outlet.

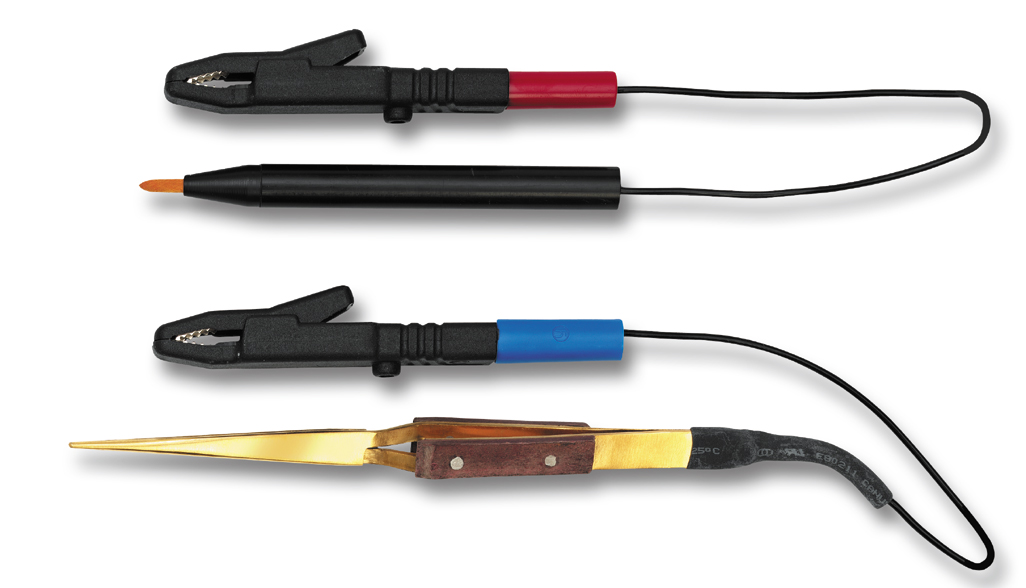

With self-tensioning cross forceps and electrode pen. The convenient alligator clip facilitates connection to a rectifier.

Preparation salt, cyanide, 50 g per litre. For all articles for degreasing before electroplating treatment.

Application:

Anodes - stainless steel

Tray - glass/PPH

Goods movement - no

Temperature - 15-30 °C

Voltage - 6-8 V

Time - 30-60 sec.

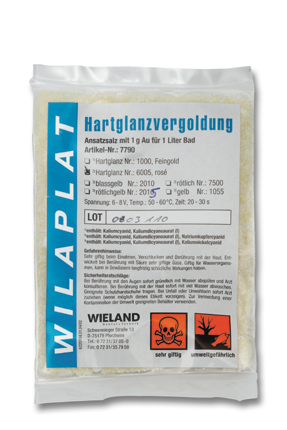

Colour:

Pale yellow 14 ct.

Preparation salt with 1 g fine gold per litre, contains cyanide. To create decorative, thin but hard colour gilding on all non-ferrous and precious metal alloys. Content: 30 g.

Application:

Anodes - stainless steel

Tray - PPH

Goods movement - no

Temperature - 50-60 °C

Voltage - 6-8 V

Time - 20-30 sec.

Colour:

red

Preparation salt with 1 g fine gold per litre, contains cyanide. To create decorative, thin but hard colour gilding on all non-ferrous and precious metal alloys. Content: 30 g.

Application:

Anodes - stainless steel

Tray - PPH

Goods movement - no

Temperature - 50-60 °C

Voltage - 6-8 V

Time - 20-30 sec.

Preparation salt, cyanide, 50 g per litre. For all articles for degreasing before electroplating treatment.

Application:

Anodes - stainless steel

Tray - glass/PPH

Goods movement - no

Temperature - 15-30 °C

Voltage - 6-8 V

Time - 30-60 sec.

Colour:

Fine gold colour

Preparation salt with 1 g fine gold per litre, contains cyanide. To create decorative, thin but hard colour gilding on all non-ferrous and precious metal alloys. Content: 30 g.

Application:

Anodes - stainless steel

Tray - PPH

Goods movement - no

Temperature - 50-60 °C

Voltage - 6-8 V

Time - 20-30 sec.

Colour:

rosegold

Preparation salt with 1 g fine gold per litre, contains cyanide. To create decorative, thin but hard colour gilding on all non-ferrous and precious metal alloys. Content: 30 g.

Application:

Anodes - stainless steel

Tray - PPH

Goods movement - no

Temperature - 50-60 °C

Voltage - 6-8 V

Time - 20-30 sec.

Colour:

Yellow 18 ct.

Preparation salt with 1 g fine gold per litre, contains cyanide. To create decorative, thin but hard colour gilding on all non-ferrous and precious metal alloys. Content: 30 g.

Application:

Anodes - stainless steel

Tray - PPH

Goods movement - no

Temperature - 50-60 °C

Voltage - 6-8 V

Time - 20-30 sec.

(Ready to use) with 4 g fine gold per litre. Contains cyanide.

Colour: yellow 20 ct.

Acidic gold plating path for creating strong gold plating on non-ferrous metals and silver alloys. Subsequently, gold in colour of your choice.

Application:

Anodes - titanium

Tray - Glass/PPH

Goods movement - yes

Temperature - 20-30 °C

Voltage - 2.8-3.5 V

Time - 10-45 sec.

(Ready to use) with 3 g of fine gold per litre. The gold bonding bath AC3 is distinguished by firmly adhering, hard, and tarnish resistant gold bonding. The bath is suited for stainless steels in addition to the conventionally galvanisable materials.

Application:

Anodes - titanium

Tray - Glass/PPH

Goods movement - yes

Temperature - 20-30 °C

Voltage - 3-4 V

Time - 10-25 min.

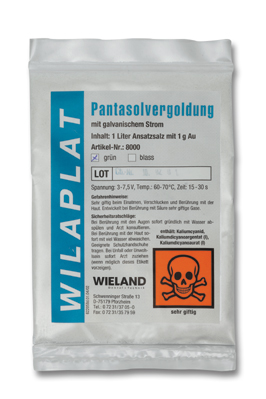

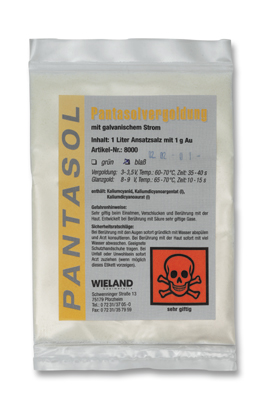

Colour:

green

With 1 g of fine gold per litre. These baths are simple, cyanide electrolytes for decorative colour gold plating of non-ferrous and precious metal alloys.

Application:

Anodes - stainless steel

Tray - PPH

Goods movement - no

Temperature - 70-90 °C

Voltage - 6-8 V

Time - 10-30 sec.

Colour:

Pale yellow 14 ct.

With 1 g of fine gold per litre. These baths are simple, cyanide electrolytes for decorative colour gold plating of non-ferrous and precious metal alloys.

Application:

Anodes - stainless steel

Tray - PPH

Goods movement - no

Temperature - 70-90 °C

Voltage - 6-8 V

Time - 10-30 sec.

Colour:

Red

With 1 g of fine gold per litre. These baths are simple, cyanide electrolytes for decorative colour gold plating of non-ferrous and precious metal alloys.

Application:

Anodes - stainless steel

Tray - PPH

Goods movement - no

Temperature - 70-90 °C

Voltage - 6-8 V

Time - 10-30 sec.

Colour:

Pale yellow 14 ct.

With 1 g of fine gold. Contents: 100 ml concentrate for one litre.

Application:

Anodes - stainless steel

Tray - PPH

Goods movement - no

Temperature - 50-60 °C

Voltage - 6-8 V

Time - 20-30 sec.

Colour:

Yellow 18 ct.

With 1 g of fine gold. Contents: 100 ml concentrate for one litre.

Application:

Anodes - stainless steel

Tray - PPH

Goods movement - no

Temperature - 50-60 °C

Voltage - 6-8 V

Time - 20-30 sec.

Colour:

rosegold

With 1 g of fine gold. Contents: 100 ml concentrate for one litre.

Application:

Anodes - stainless steel

Tray - PPH

Goods movement - no

Temperature - 50-60 °C

Voltage - 6-8 V

Time - 20-30 sec.

Colour:

Red

With 1 g of fine gold. Contents: 100 ml concentrate for one litre.

Application:

Anodes - stainless steel

Tray - PPH

Goods movement - no

Temperature - 50-60 °C

Voltage - 6-8 V

Time - 20-30 sec.

Colour:

Fine gold colour

With 1 g of fine gold. Contents: 100 ml concentrate for one litre.

Application:

Anodes - stainless steel

Tray - PPH

Goods movement - no

Temperature - 50-60 °C

Voltage - 6-8 V

Time - 20-30 sec.

(Ready to use). High-performance bath with levelling effect, good throwing power and excellent gloss creation.

Application:

Anodes - nickel

Tray - PPH

Goods movement - yes

Temperature - 40-60 °C

Voltage - 1.8-4.0 V

(Ready to use). With 30 g of fine silver per litre. Contains cyanide. Achieves high-gloss silver layers.

Application:

Anodes - fine silver

Tray - Glass/PPH

Goods movement - yes

Temperature - 20-30 °C

Voltage - 0.5-1.0 V

Time - 5-50 min.

Concentrate with 2 g of rhodium per litre.

The products achieve dark, anthracite rhodium plating and are extremely resistant to abrasion.

Application:

Anodes - titanium

Tray - Glass/PPH

Goods movement - yes

Temperature - 18-25 °C

Voltage - 1.8-2.2 V

Time - 2-7 min.

Concentrate with 2 g of rhodium per litre.

This bath produces a brilliant, high white colour and is highly abrasion resistant.

Application:

Anodes - titanium

Tray - Glass/PPH

Goods movement - yes

Temperature - 20-25 °C

Voltage - 1.8-2.2 V

Time - 2-5 minutes

For covering all soft stones with hardness of less than 7, such as coral, pearl, lapizlazuli, turquoise. The paint can be carefully removed with acetone.

To specifically cover small areas, Covering lacquer can be removed later with alcohol. Felt tip insert individual 4 637 106.

Ready to use, for pre-treating non-metallic materials before copper-plating. Can also be used for bridging electrical conductor lines.

Replacements

Temperature-resistant up to 80 °C. Capacity 1.5 litres.

Product information "Galvanising unit KGA 2000"

Rectifier and tray part in plastic housing.

- Max. power 15 A

- Voltage adjustable steplessly from 0-15 volts

- Residual ripple of the rectifier approx. 48%

- Analogue display via voltmeter and amperemeter

- Transparent plastic cover

- Stepless temperature control from 20-100 °C

- Articles move horizontally through all processing trays via a cathode rod

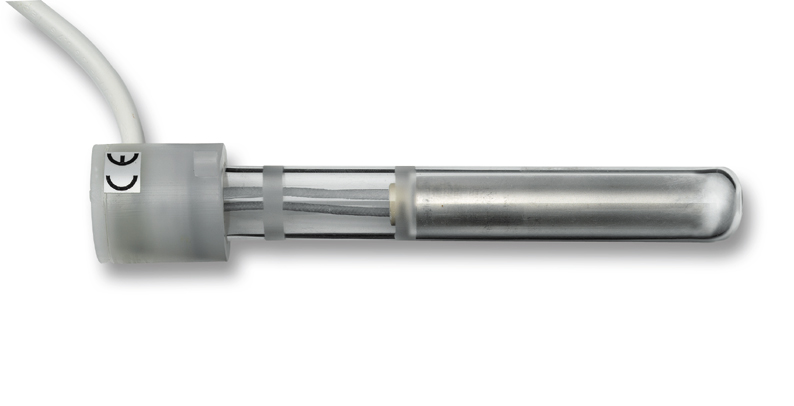

- Connection for quartz immersion heater (option 4 590 063)

- Connection socket for electroplating (option 4 591 052)

Includes

- 3 each of processing and rinsing trays made of plastic, 1.5 litres each

- Temperature sensor with holder

- Max. power 15 A

- Voltage adjustable steplessly from 0-15 volts

- Residual ripple of the rectifier approx. 48%

- Analogue display via voltmeter and amperemeter

- Transparent plastic cover

- Stepless temperature control from 20-100 °C

- Articles move horizontally through all processing trays via a cathode rod

- Connection for quartz immersion heater (option 4 590 063)

- Connection socket for electroplating (option 4 591 052)

Includes

- 3 each of processing and rinsing trays made of plastic, 1.5 litres each

- Temperature sensor with holder