-

Craft & creative

-

Advent calendar

-

Everything about molding

-

Everything about wood

-

Handicraft sets and tools

-

Poker work

-

Encaustic

-

Experiments

-

Colors & polish

-

Galvanizing

-

(Glass) Engraving

-

Kerzen gießen

-

Adhesives

-

Crib construction

-

Jigsaw

-

Soldering & welding

-

Model kits

-

Collector models

-

Sharpening

-

Writing instruments

-

Soap casting

-

teifoc stone building sets

-

Gilding

- Tools & machines

-

Pouring tin - material and equipment

-

Advent calendar

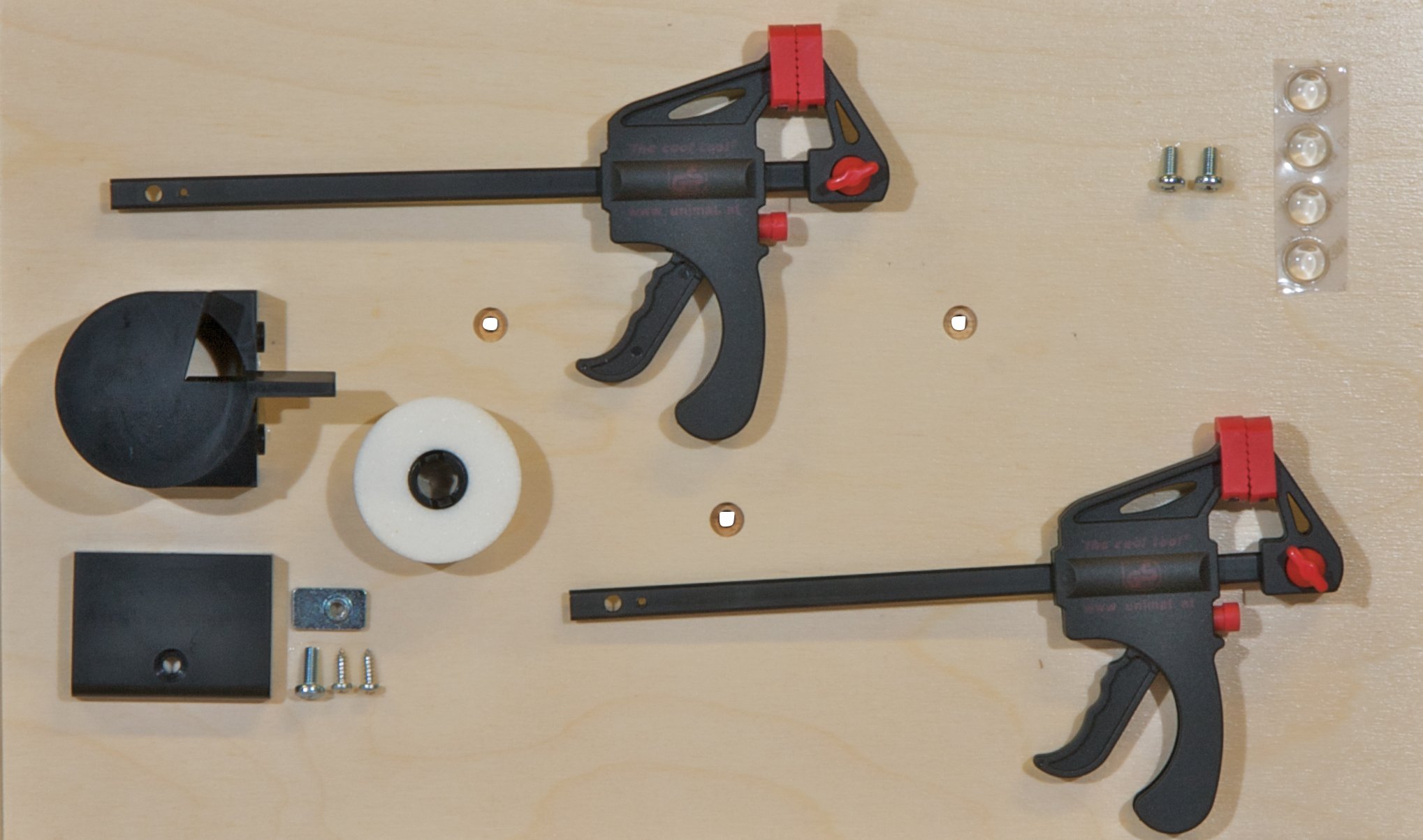

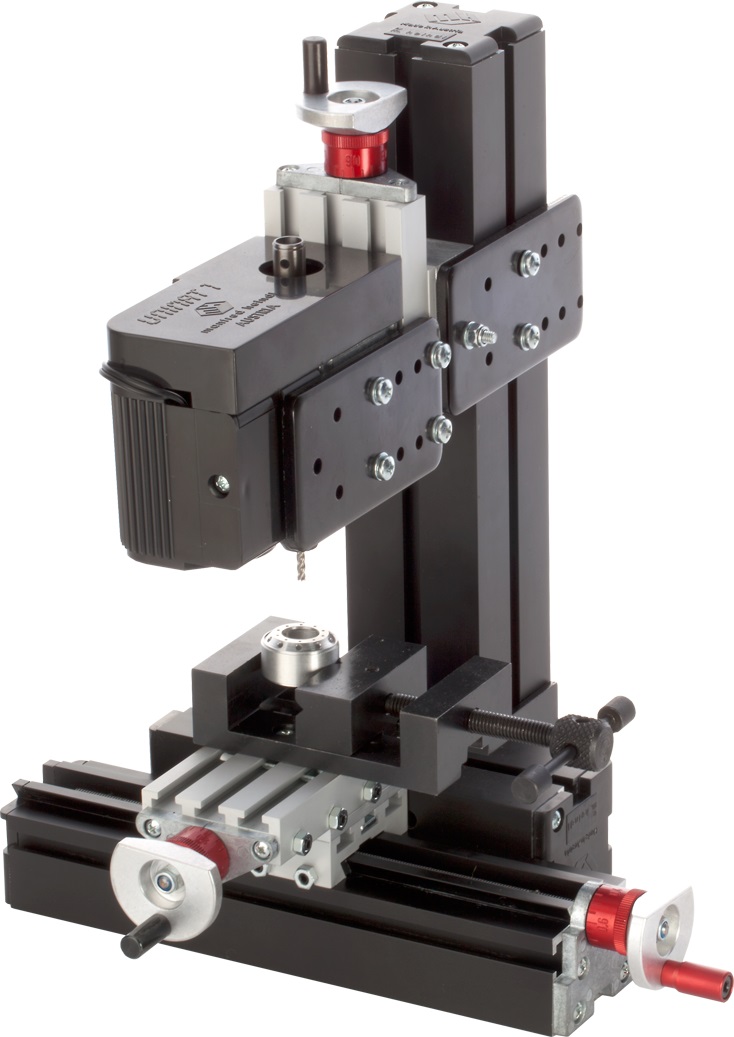

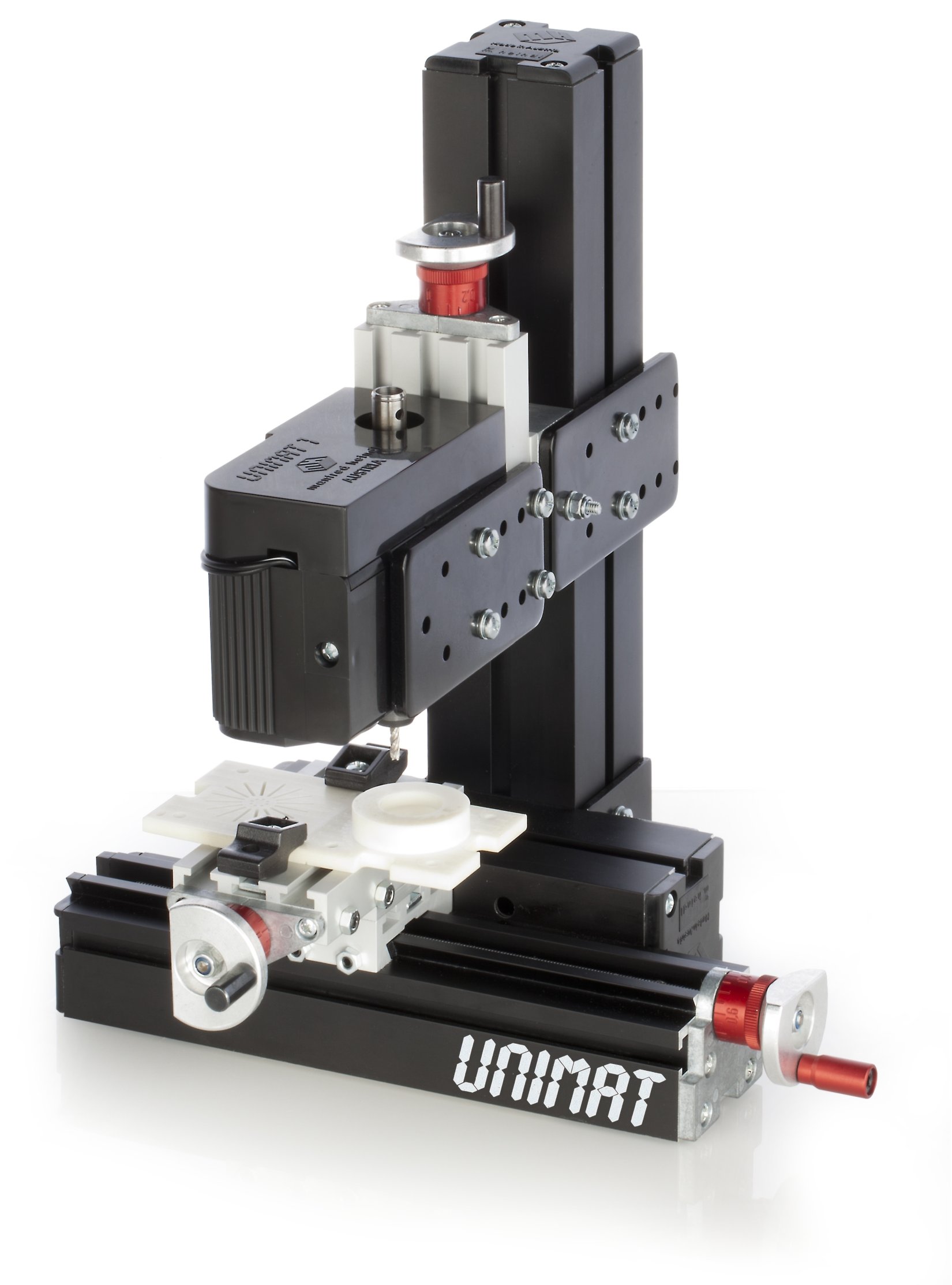

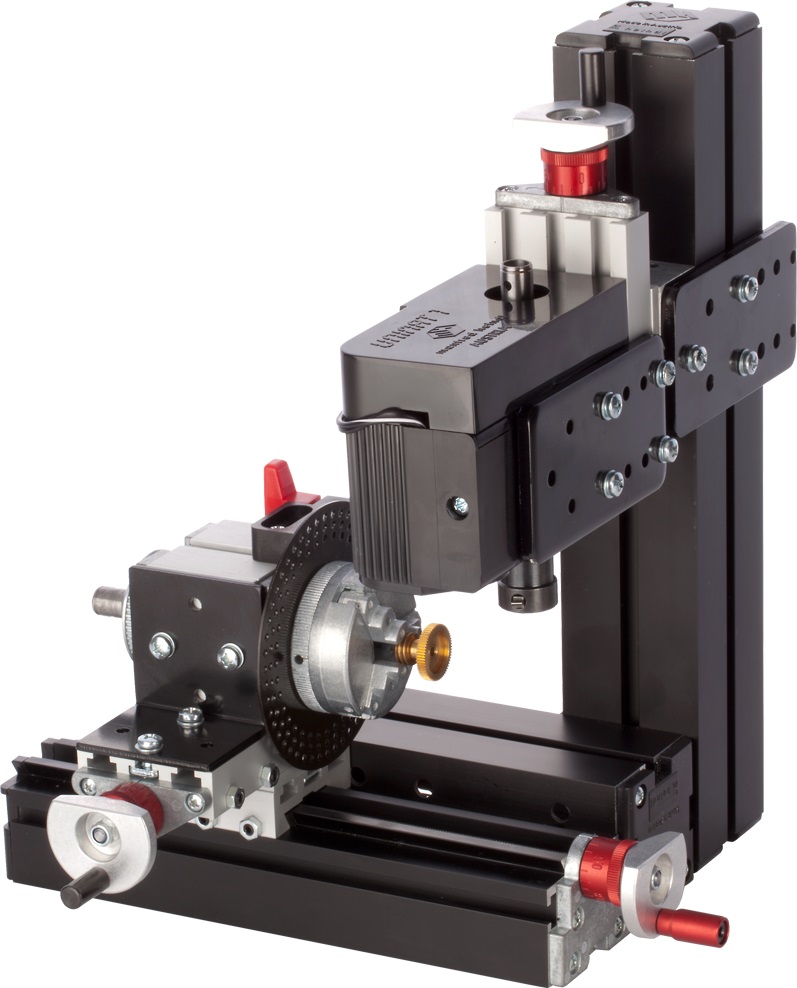

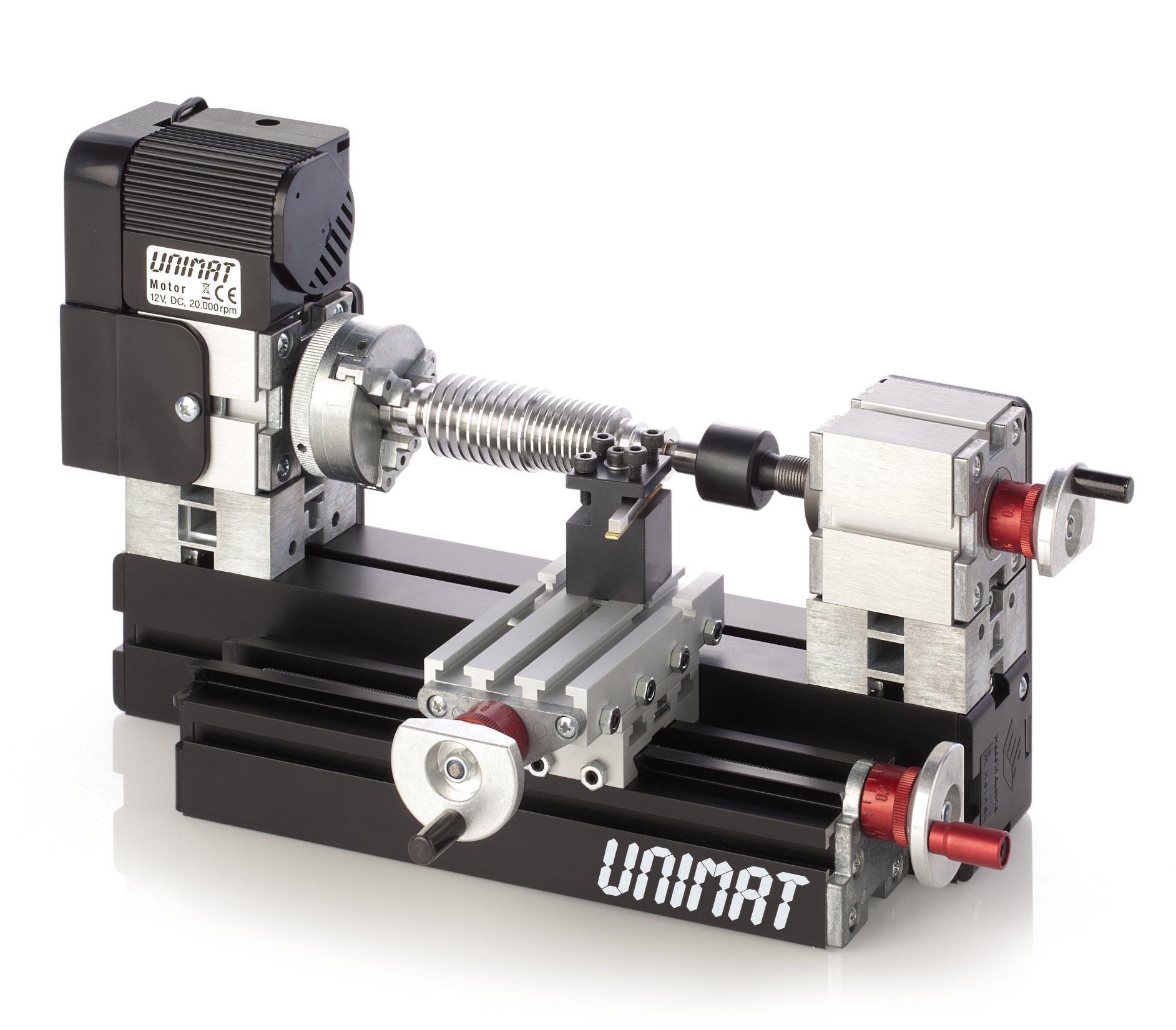

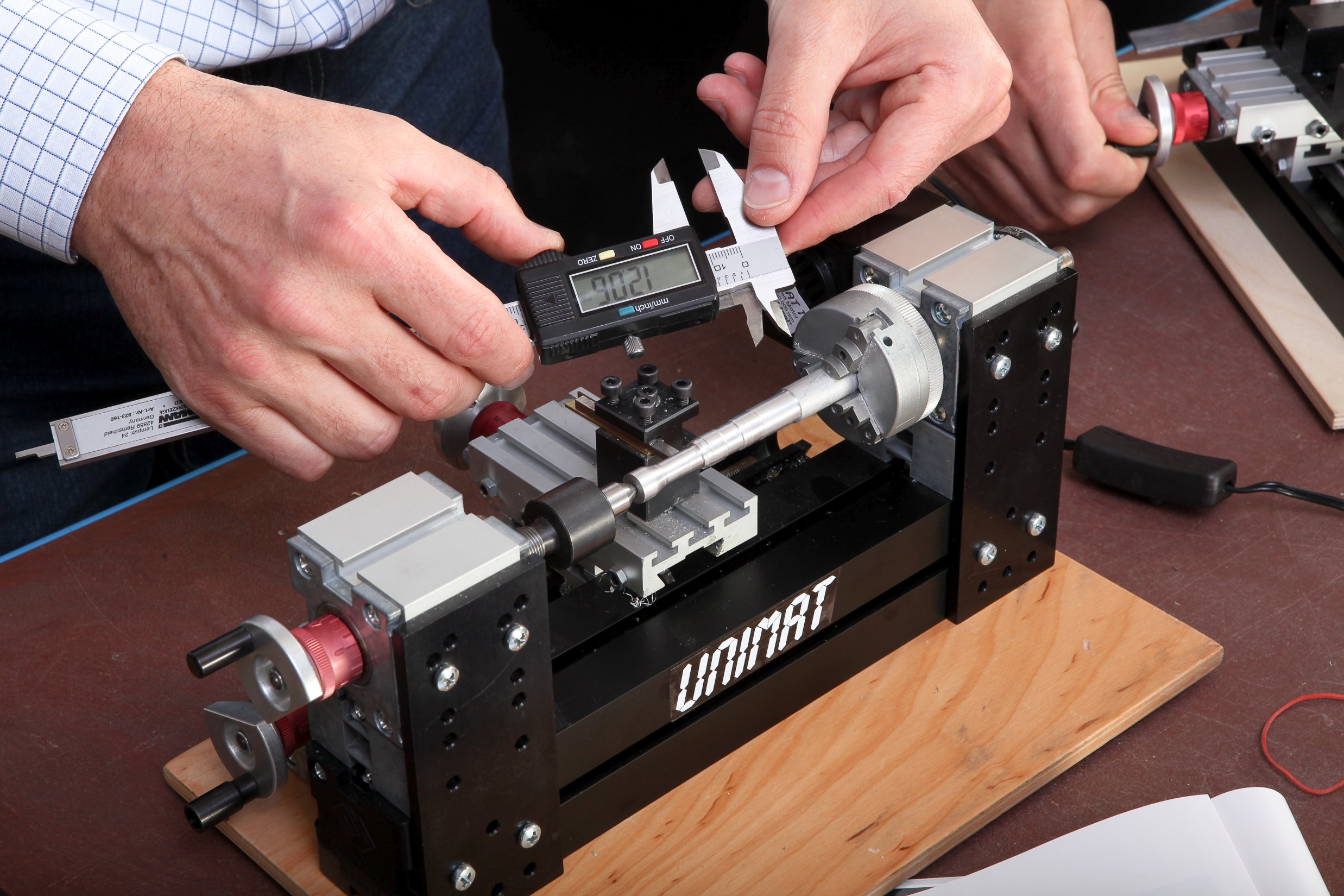

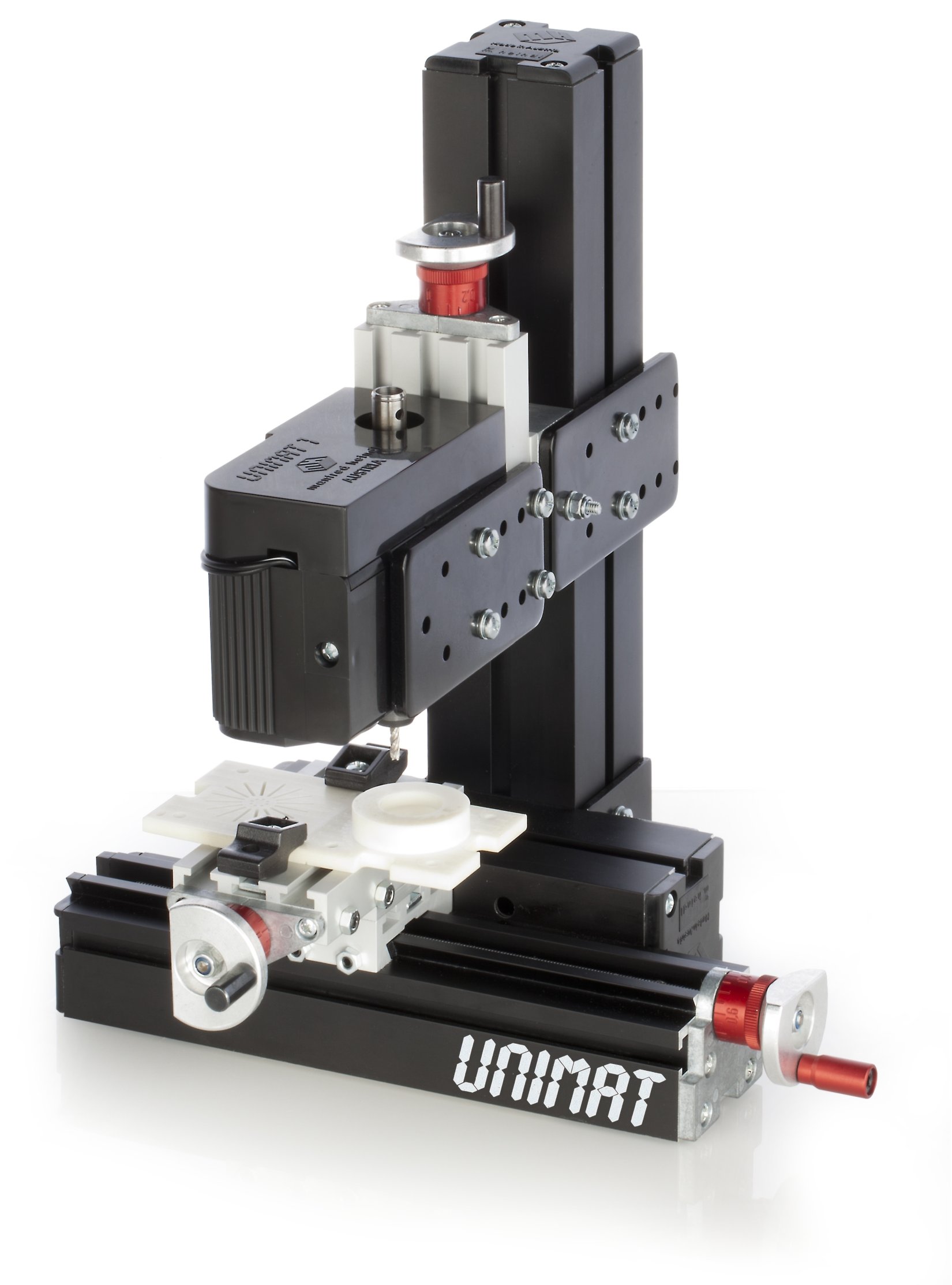

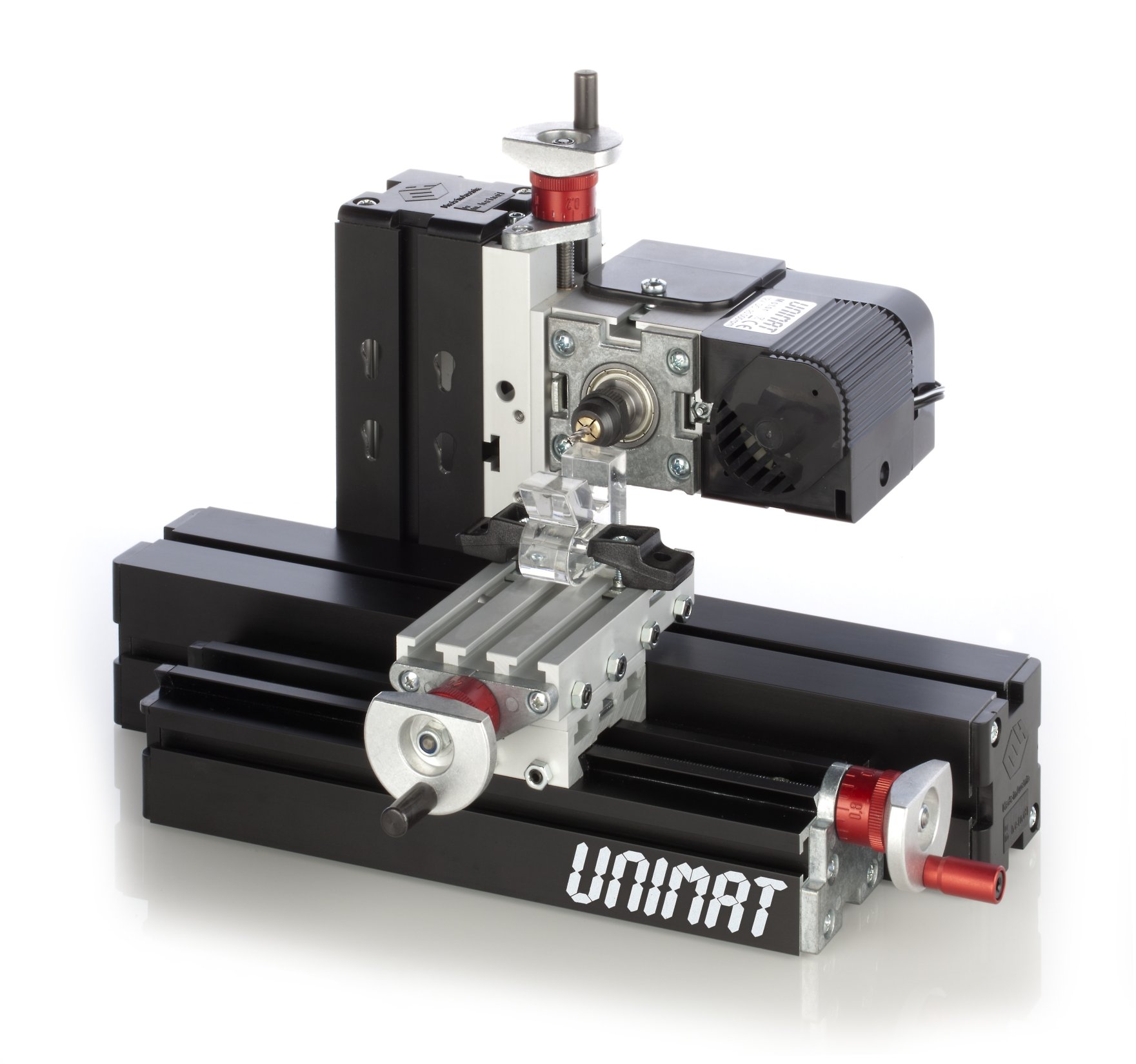

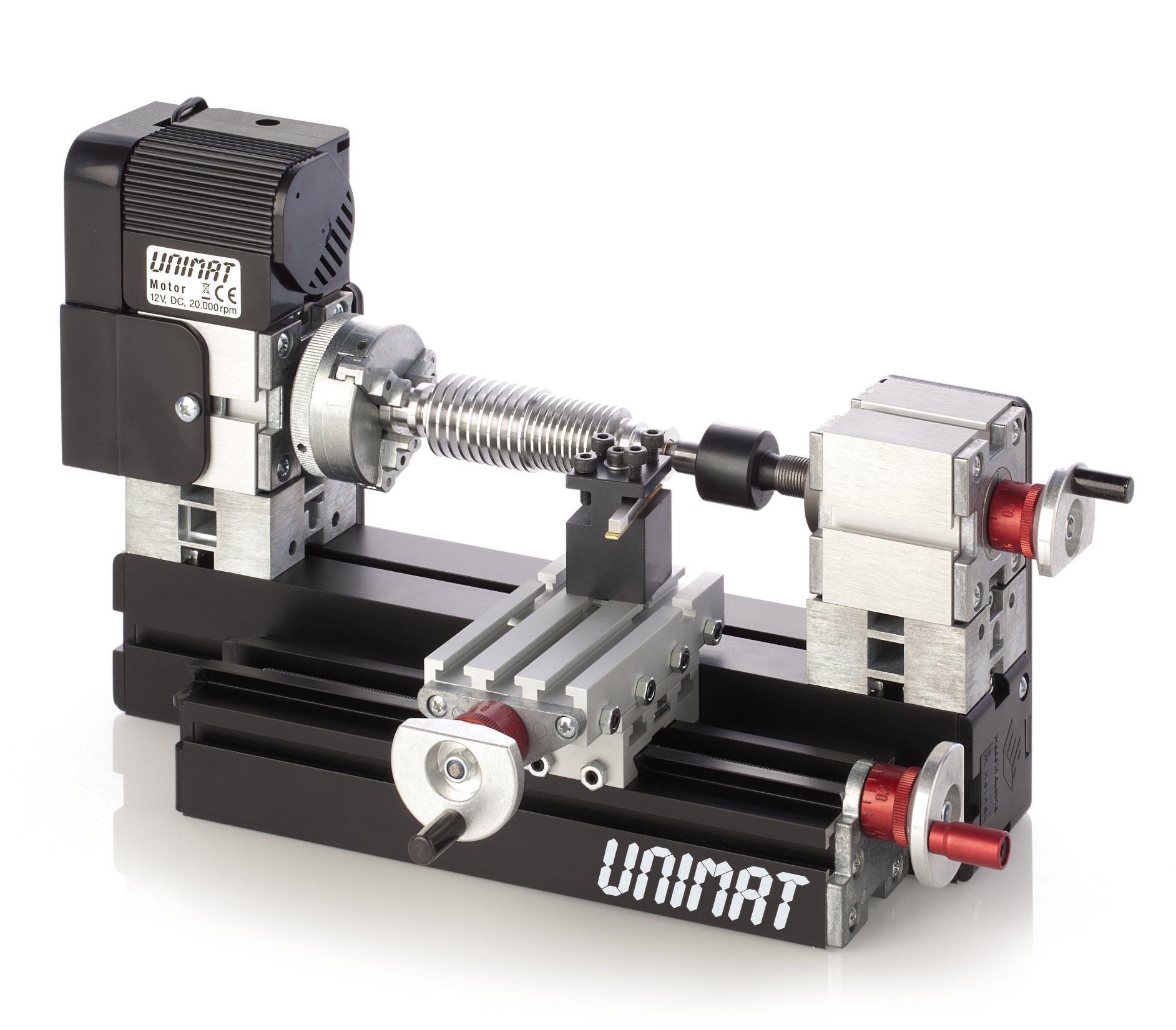

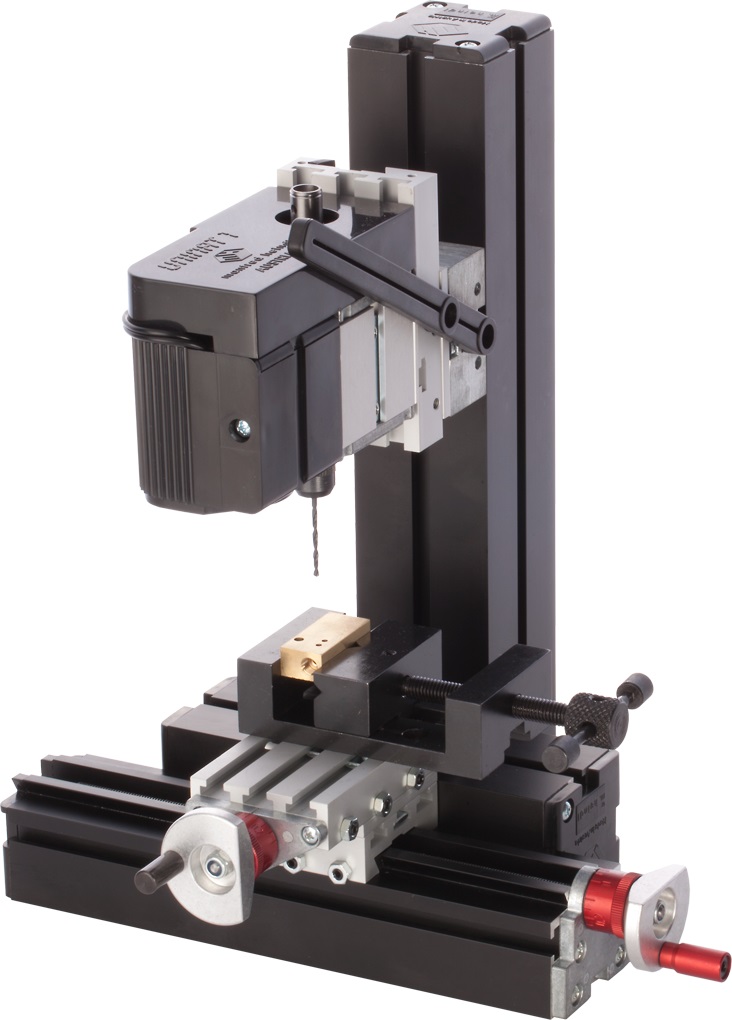

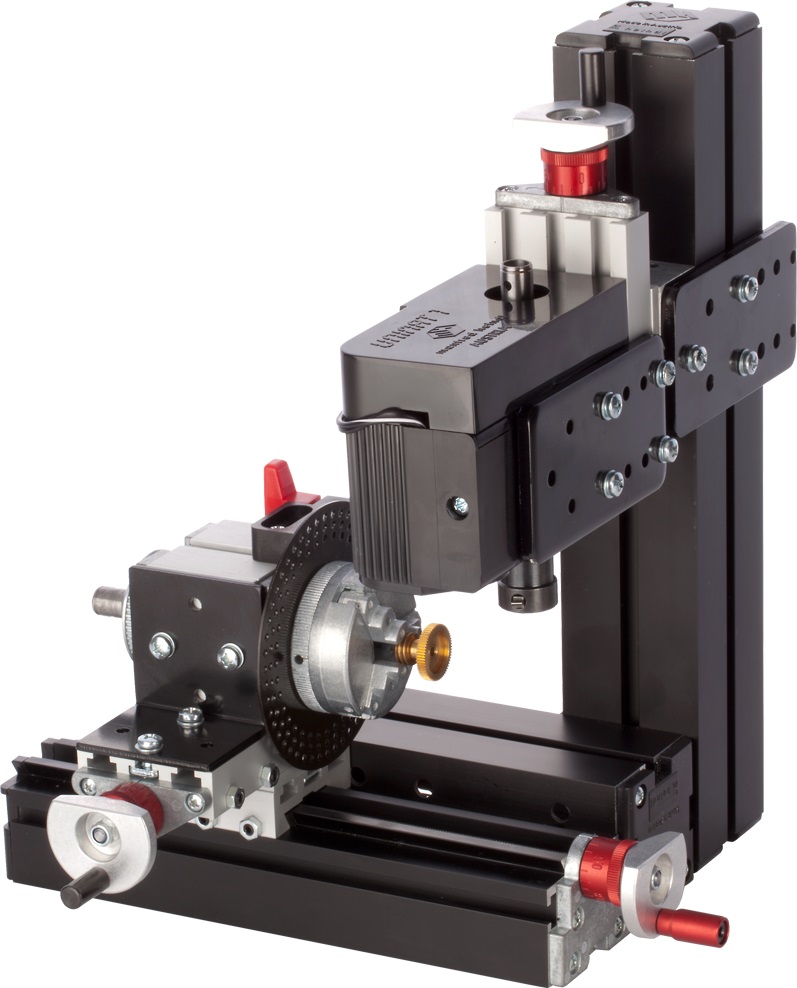

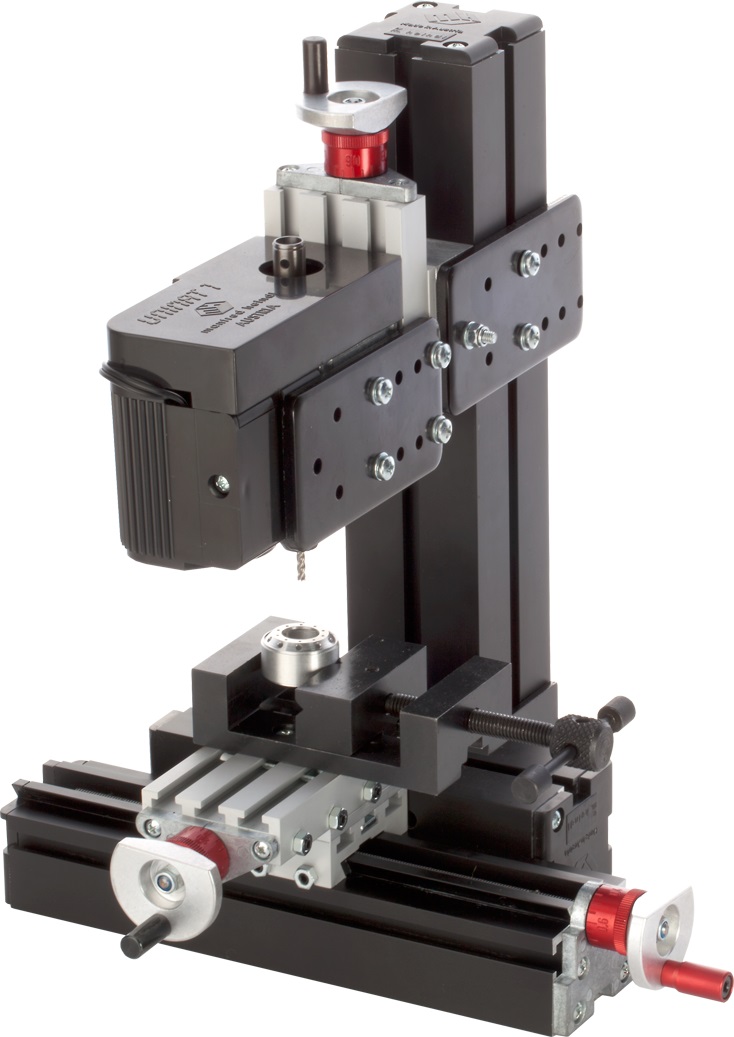

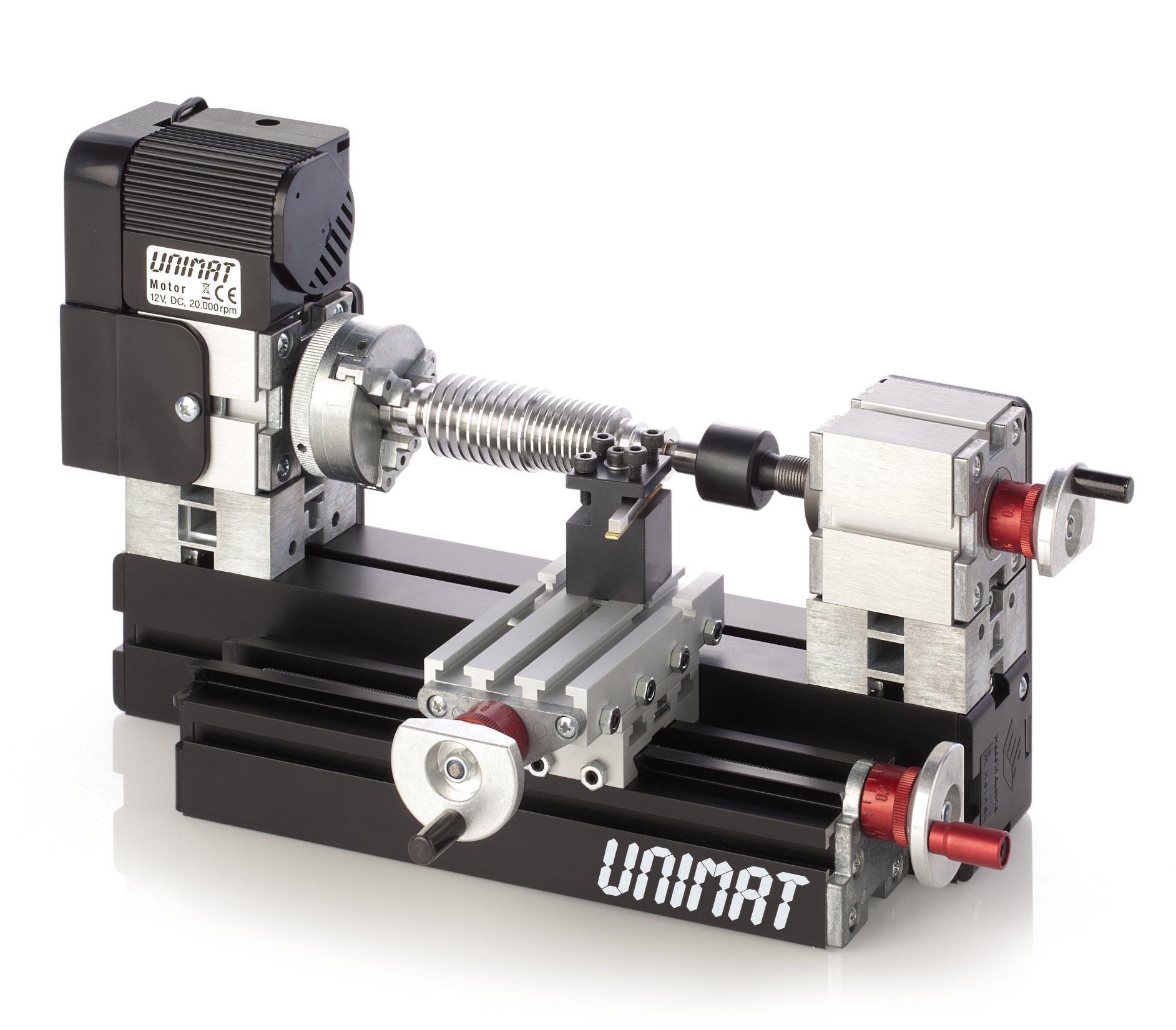

Modeling Tool Kit 6in1 - for metalwork

- Description New - for the professional user: While the Basic tool kit (P / N 341242) is designed especially for woodworking, the Unimat… More

- Reviews

-

Productvideos

By viewing the video you agree that your data will be transferred to vimeo and that you have read the Privacy policy.

By viewing the video you agree that your data will be transferred to vimeo and that you have read the Privacy policy.

By viewing the video you agree that your data will be transferred to vimeo and that you have read the Privacy policy.

By viewing the video you agree that your data will be transferred to vimeo and that you have read the Privacy policy.

By viewing the video you agree that your data will be transferred to vimeo and that you have read the Privacy policy.

By viewing the video you agree that your data will be transferred to vimeo and that you have read the Privacy policy.

| Application: | MetalLine for metalwork |

|---|---|

| Article name: | Modeling Tool Kit 6in1 |

| Brand: | COOL TOOL |

| Content: | 1,00 |

| Special feature: | 6 in 1 |

| Speed R/min: | 20000 U/Min |

| Volt/Hz: | 100-240 |

Manufacturer Informations

Name: The Cool Tool GmbH

Street: Fabriksgasse 15

City: 2340 Mödling

Country: AT

Email: info@thecooltool.com

Phone: +43 2236 / 892 666

0 of 0 reviews

Login

Accessoires (optional)

Replacements

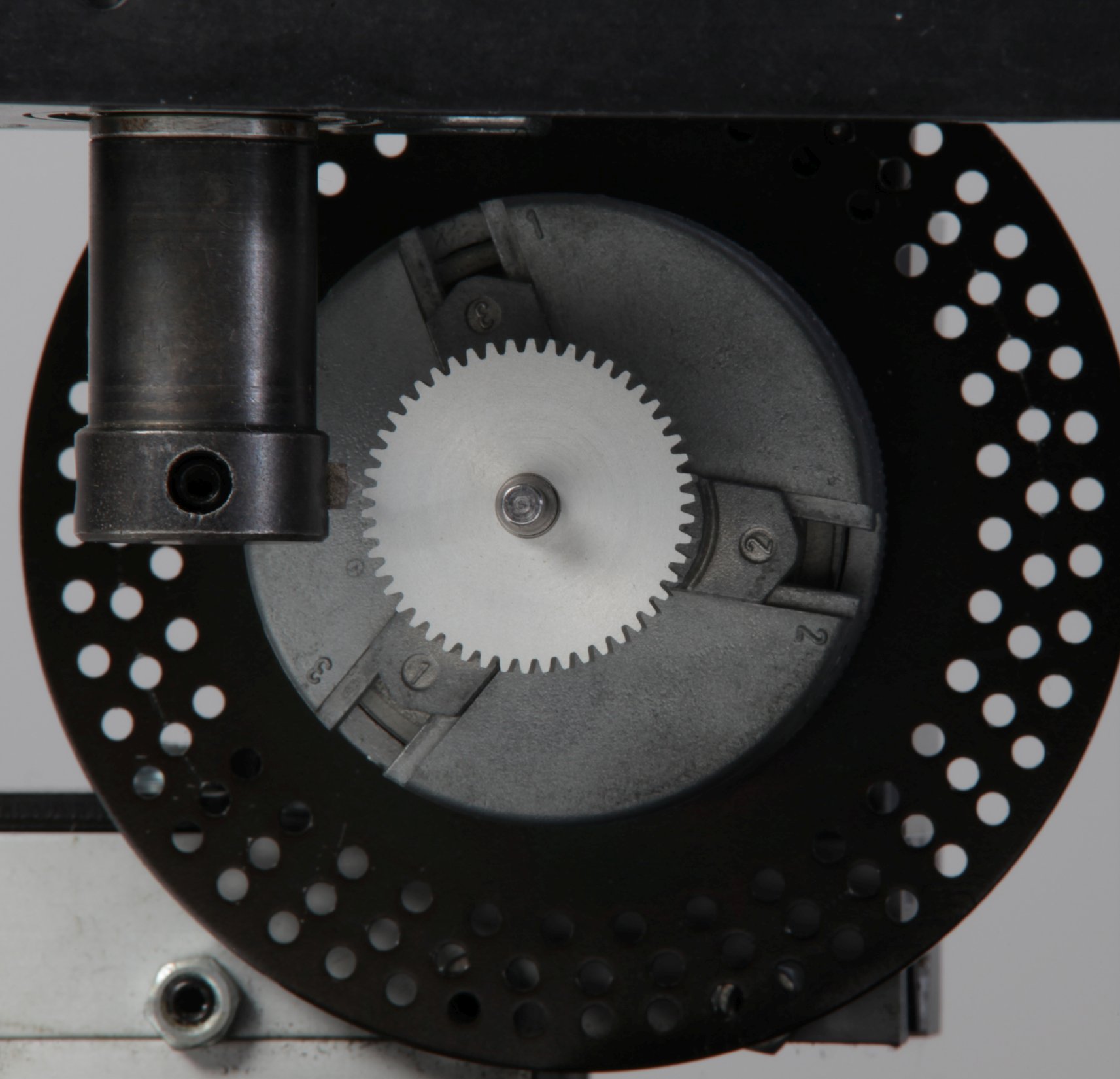

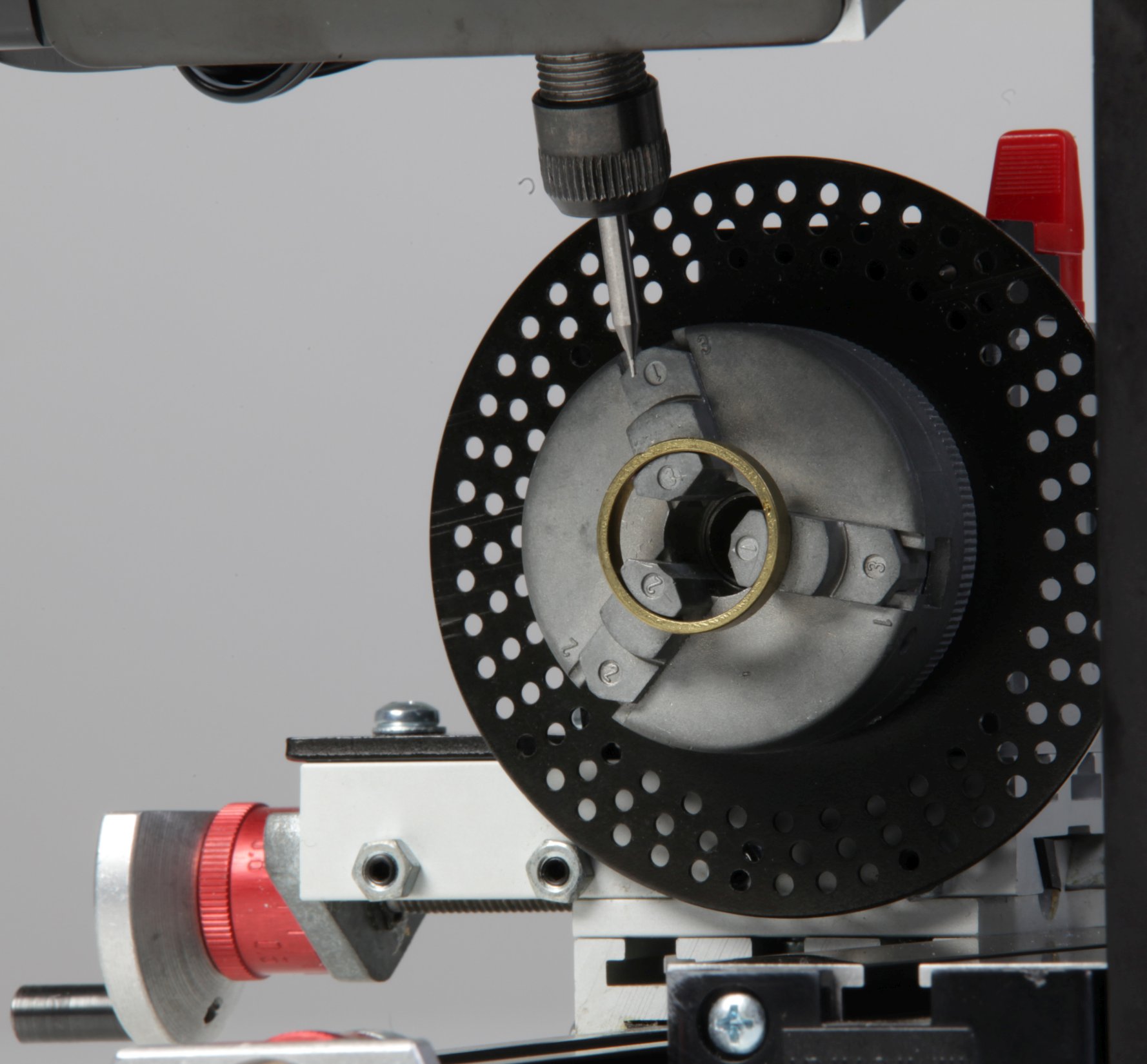

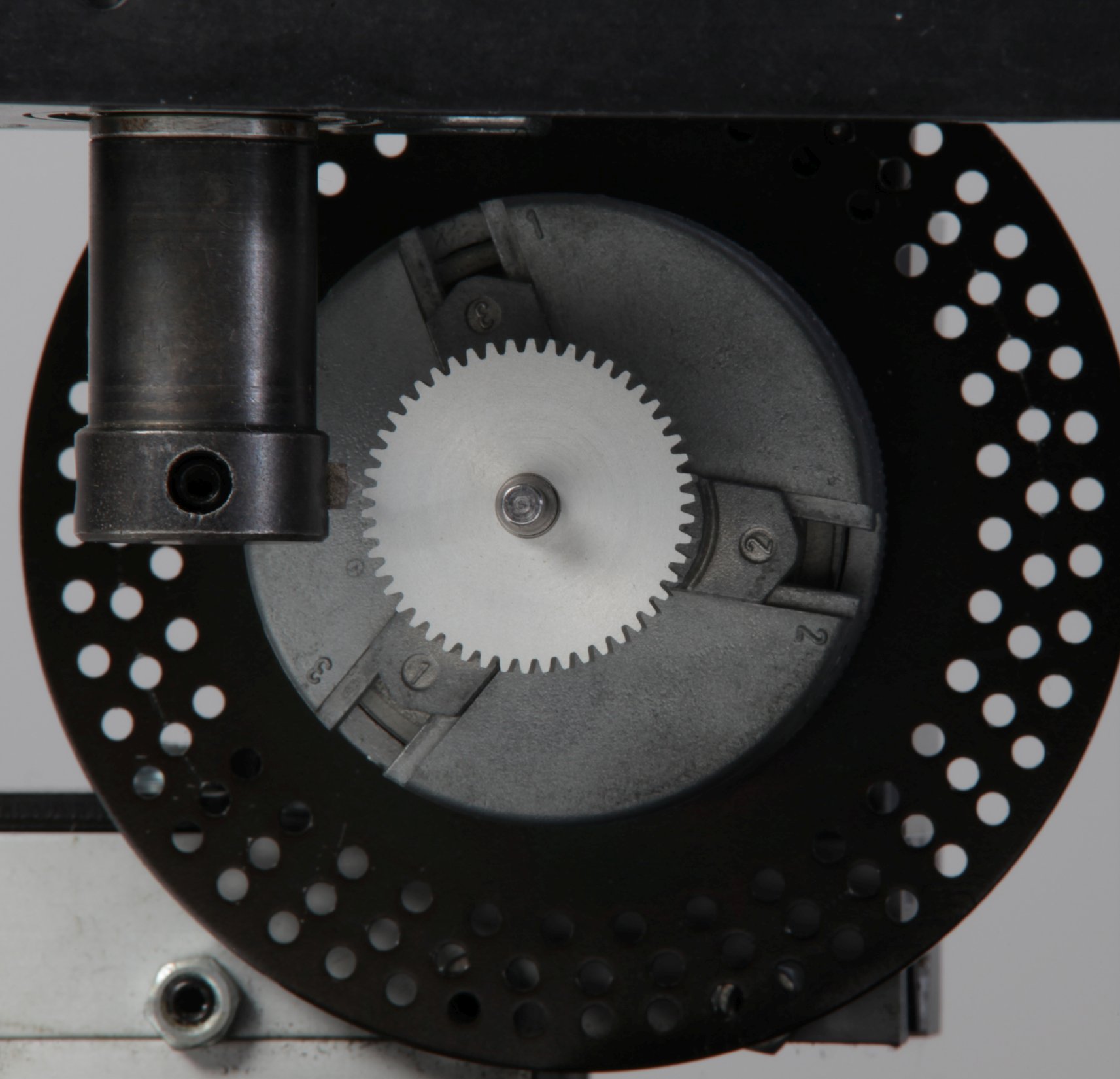

Modular, precise, robust: in addition to modularity, the precisely optimally matched GANZMETALL components ensure maximum accuracy for all machine variants.

Features that convince every professional:

- High stability, high precision

- Lowest tolerances due to precisely fitting bearing seats

- High concentricity due to dust-protected industrial ball bearings

- Reorderable backlash and adjustable dovetail designs

- Milled planers, ground and matched components

- Easy handling, modular design

- Due to increased wall thickness of the profiles significantly warp resistant and stable

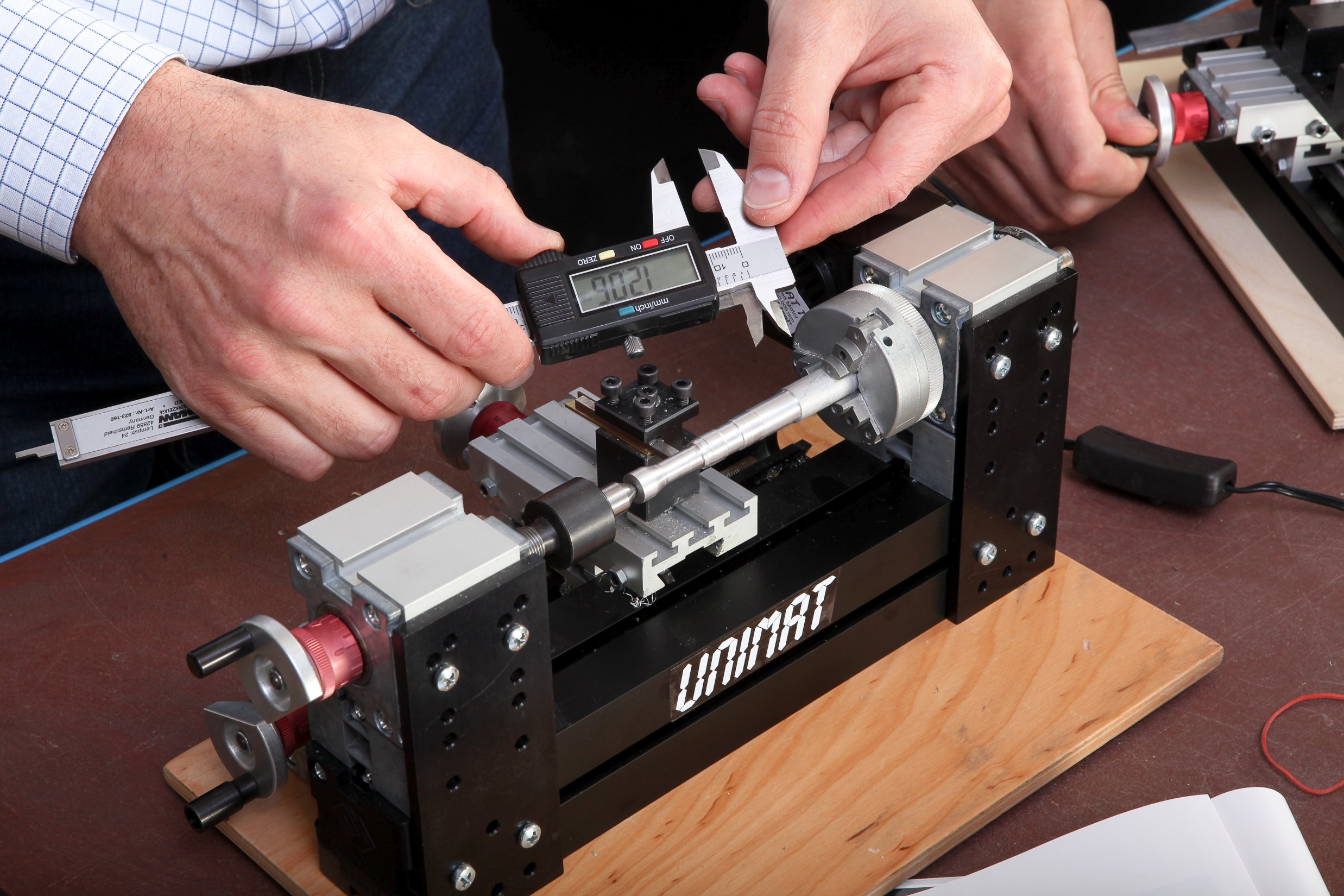

- Exact quill stroke by metal handwheels with adjustable vernier and 0.05mm scale

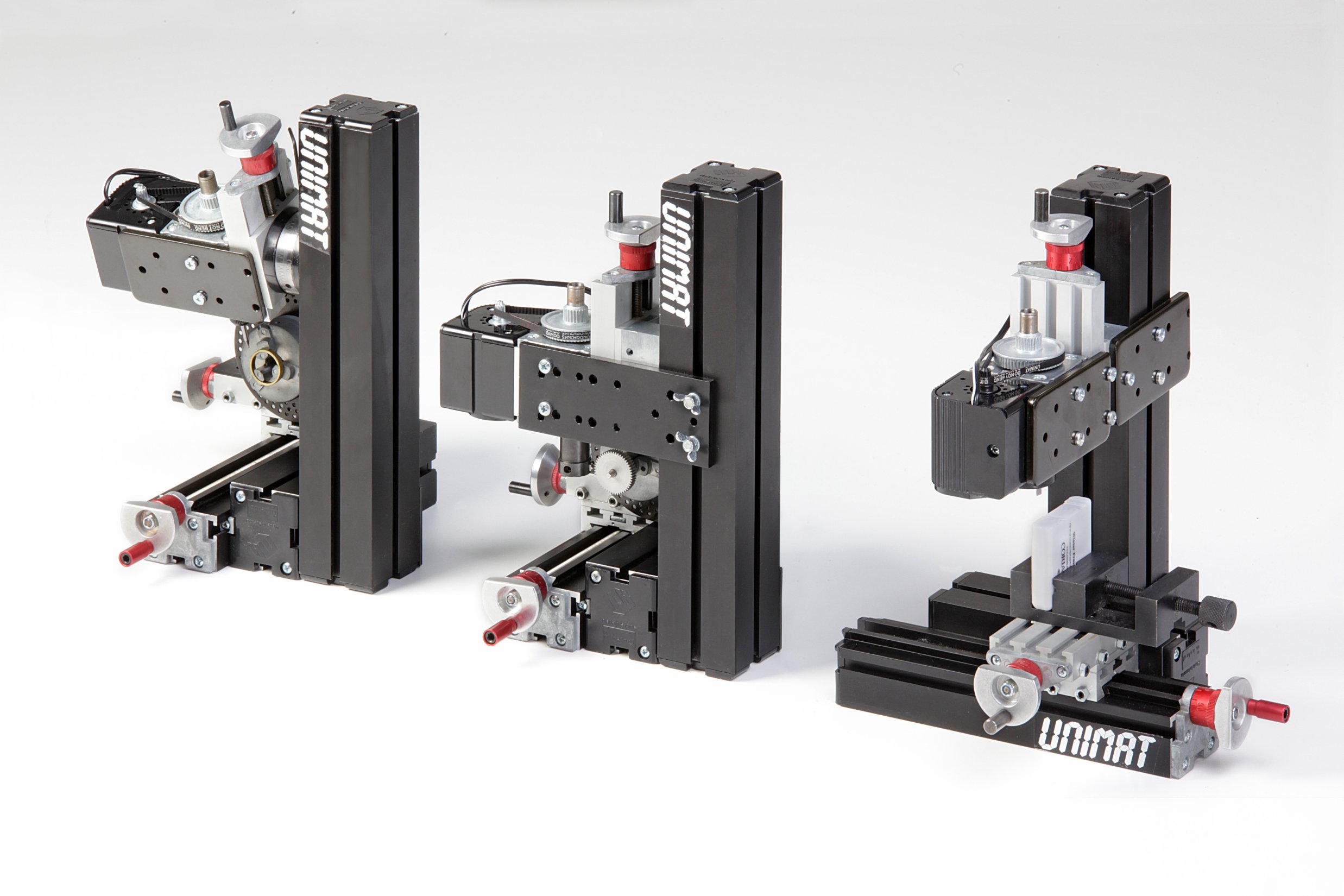

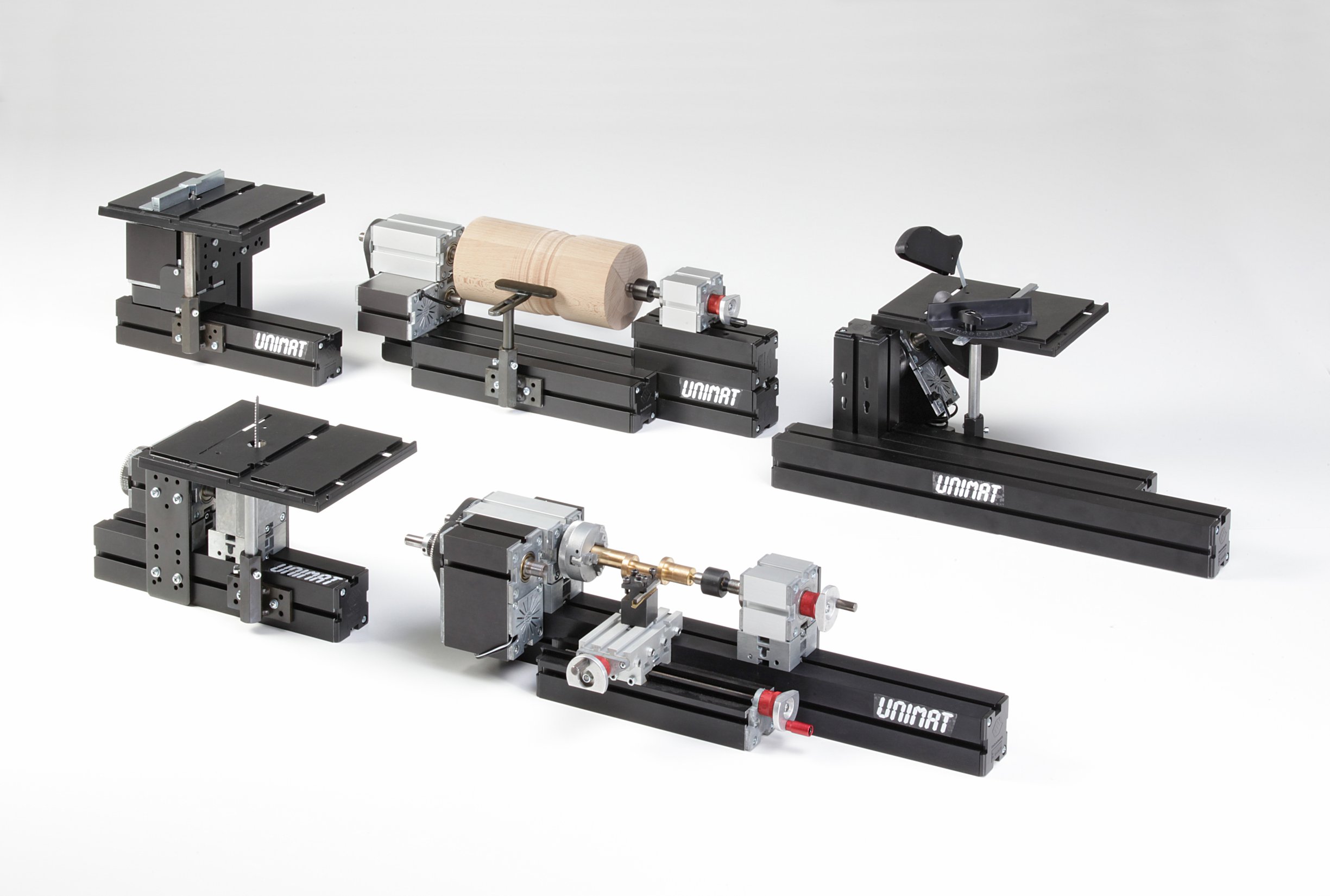

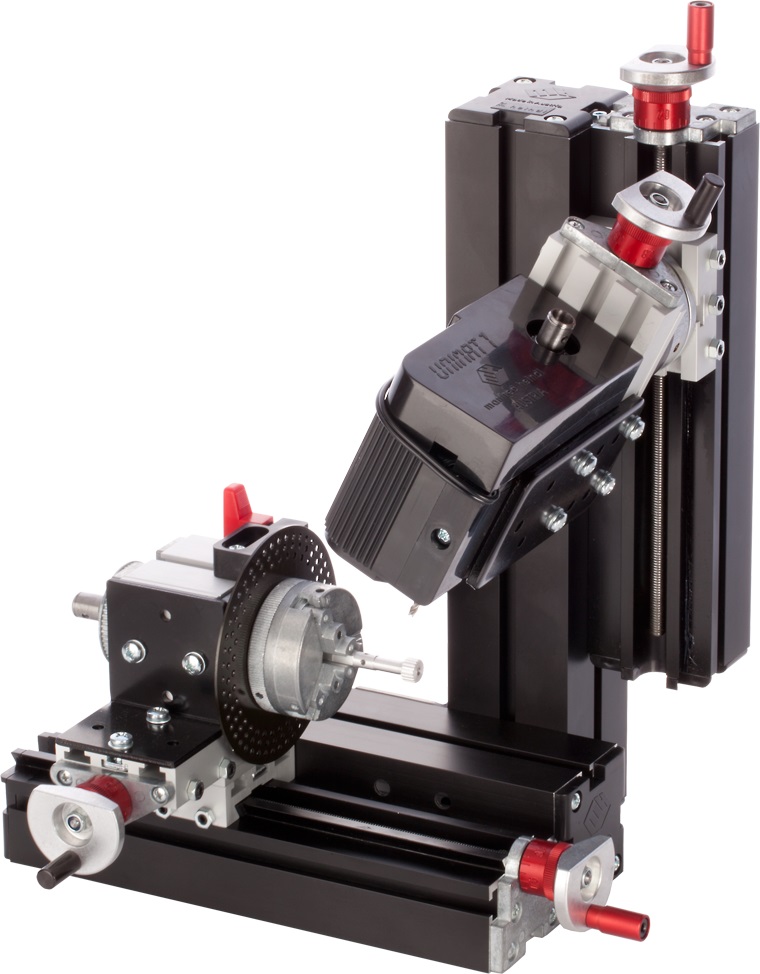

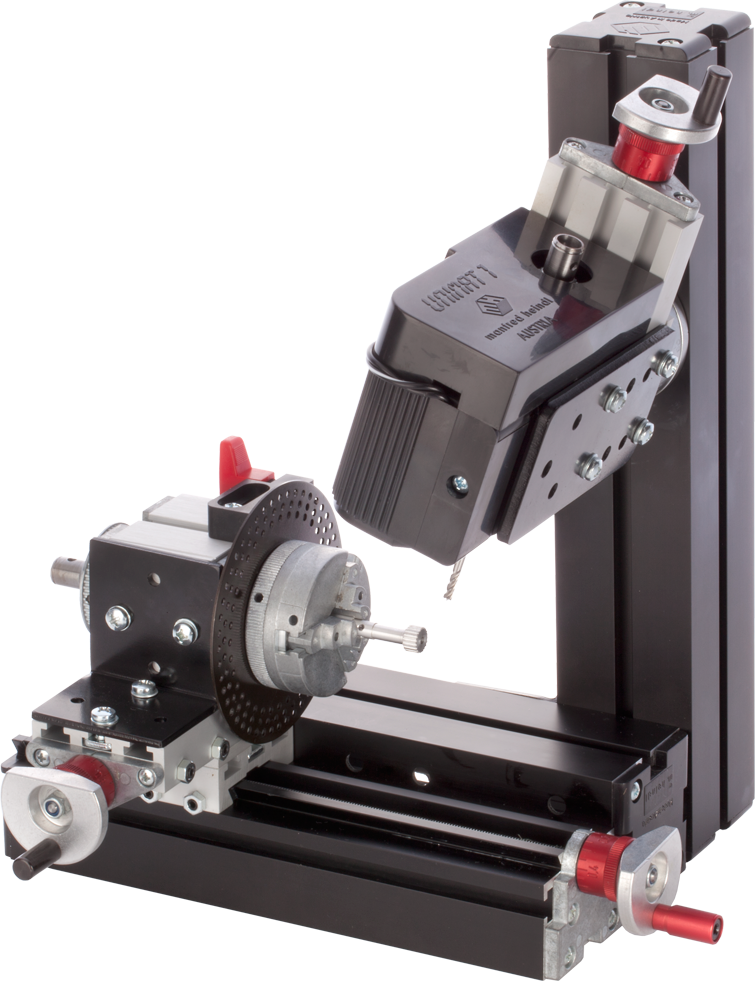

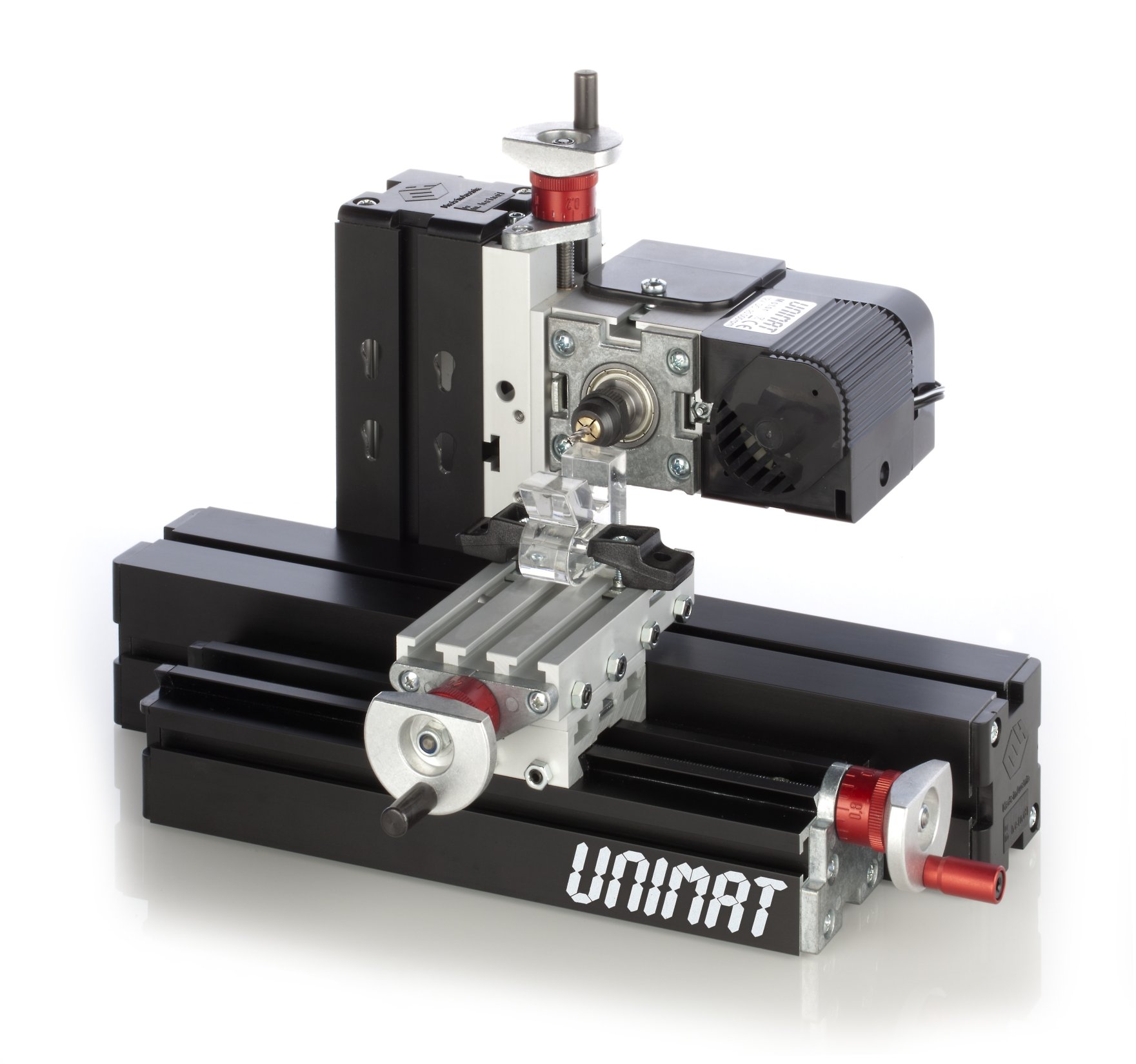

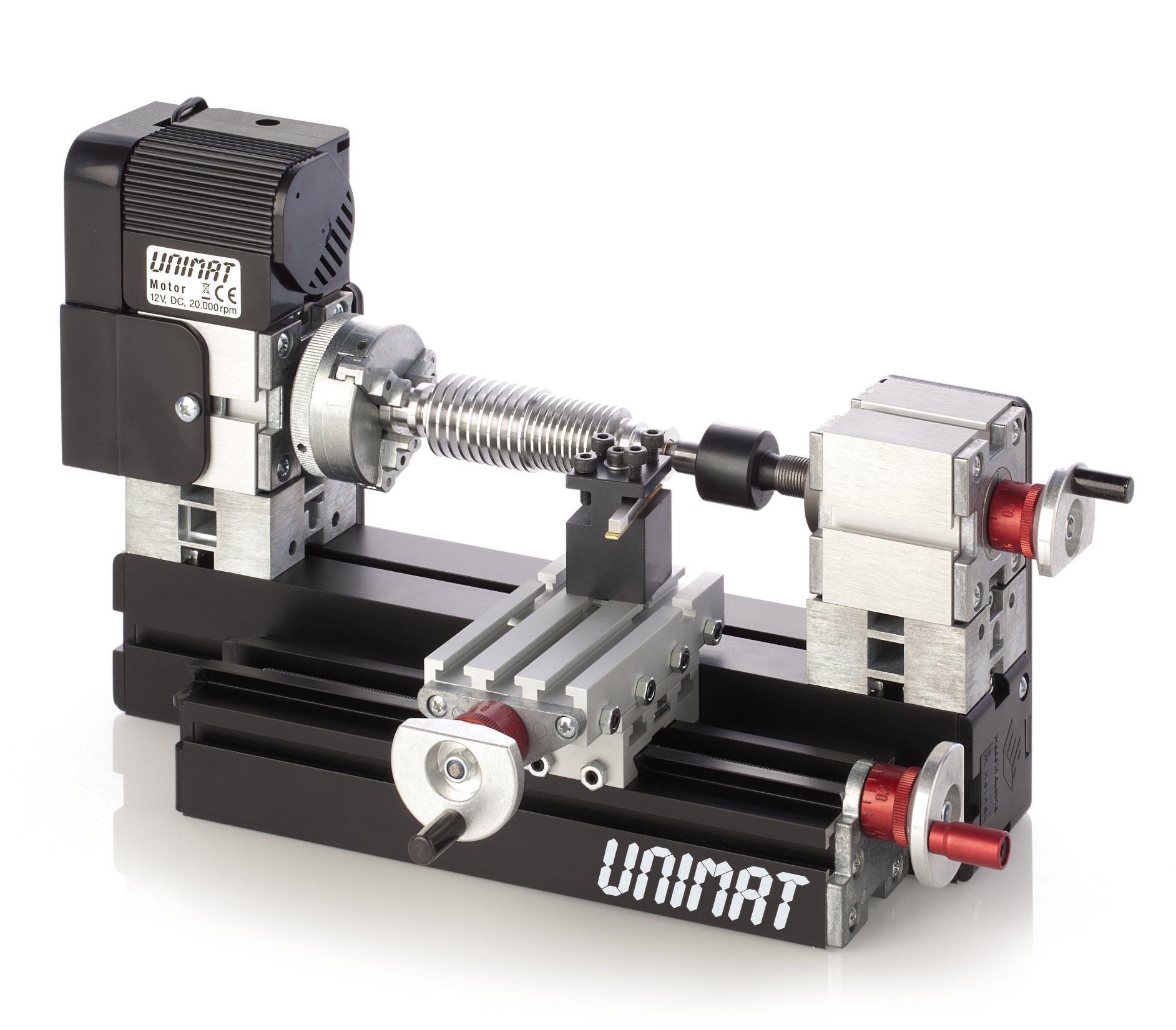

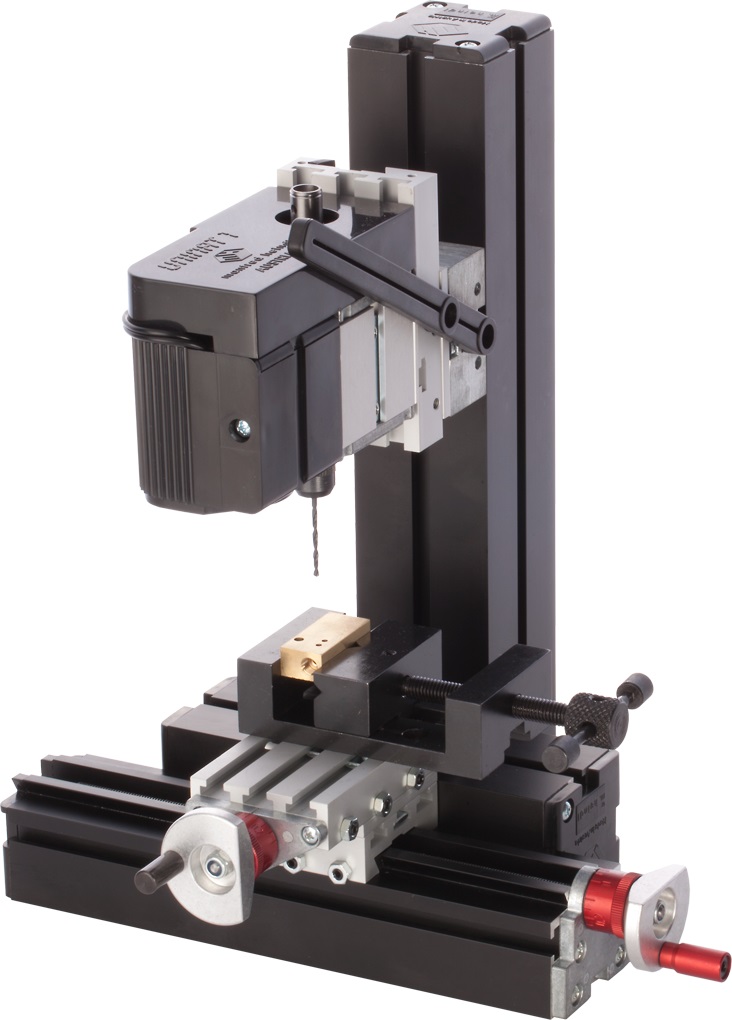

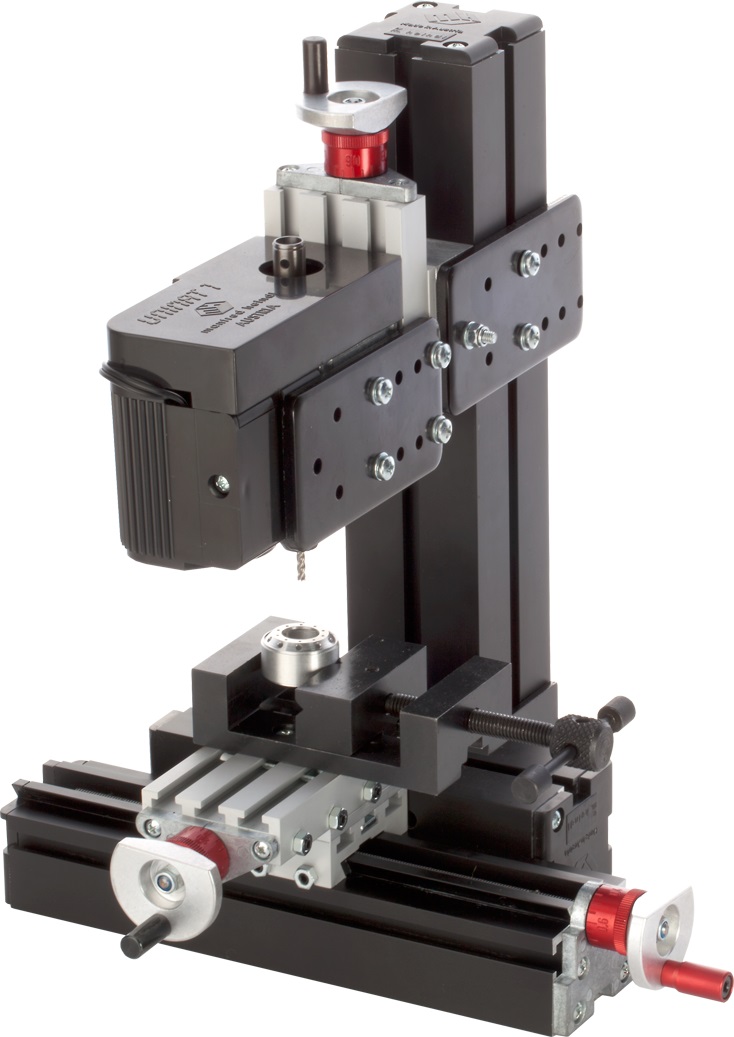

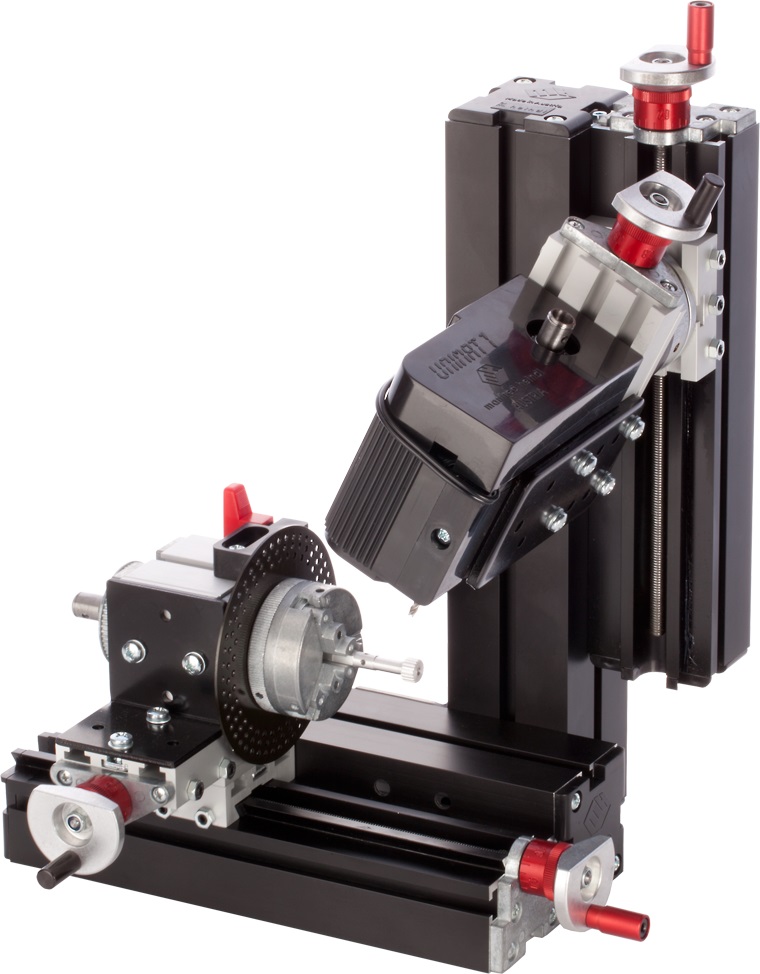

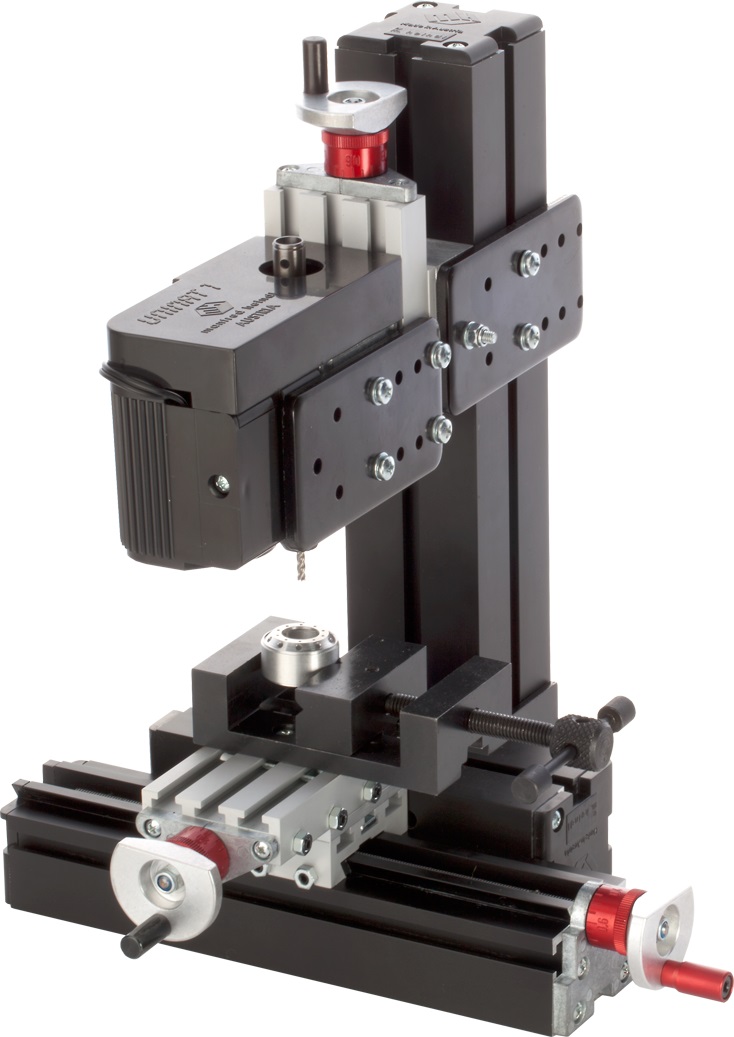

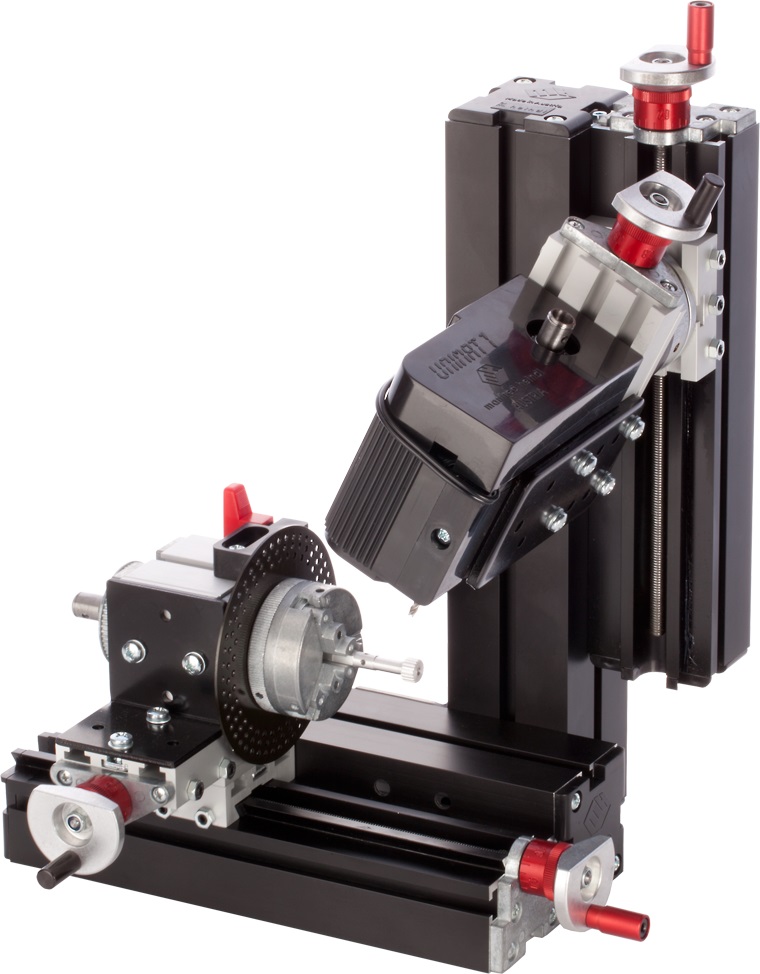

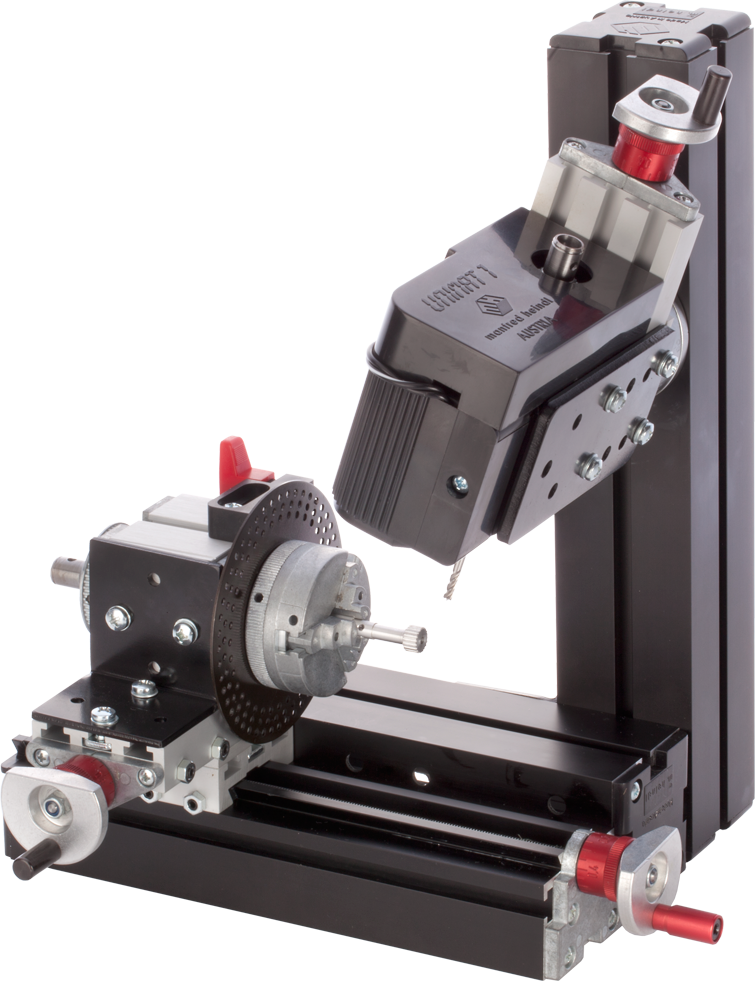

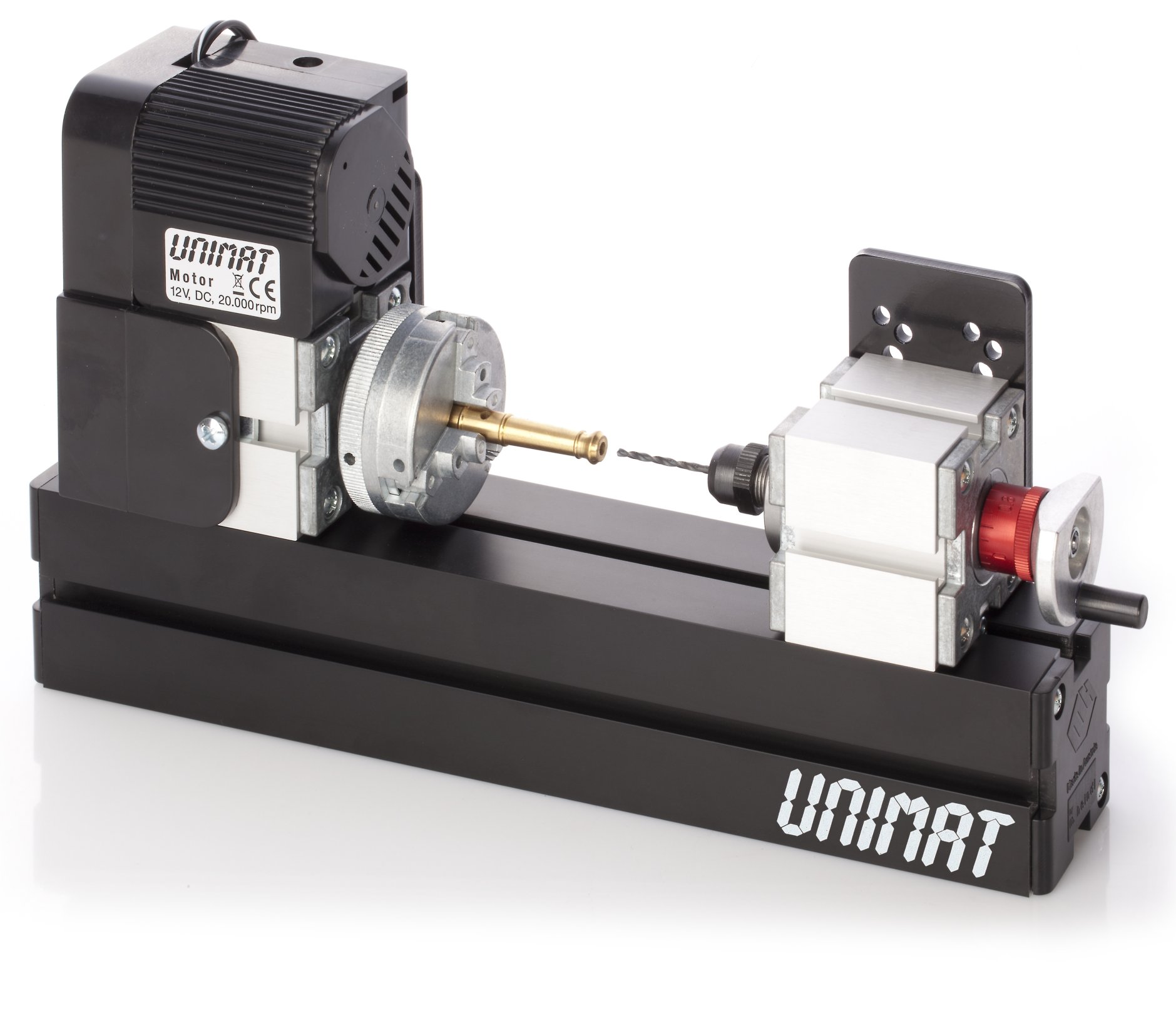

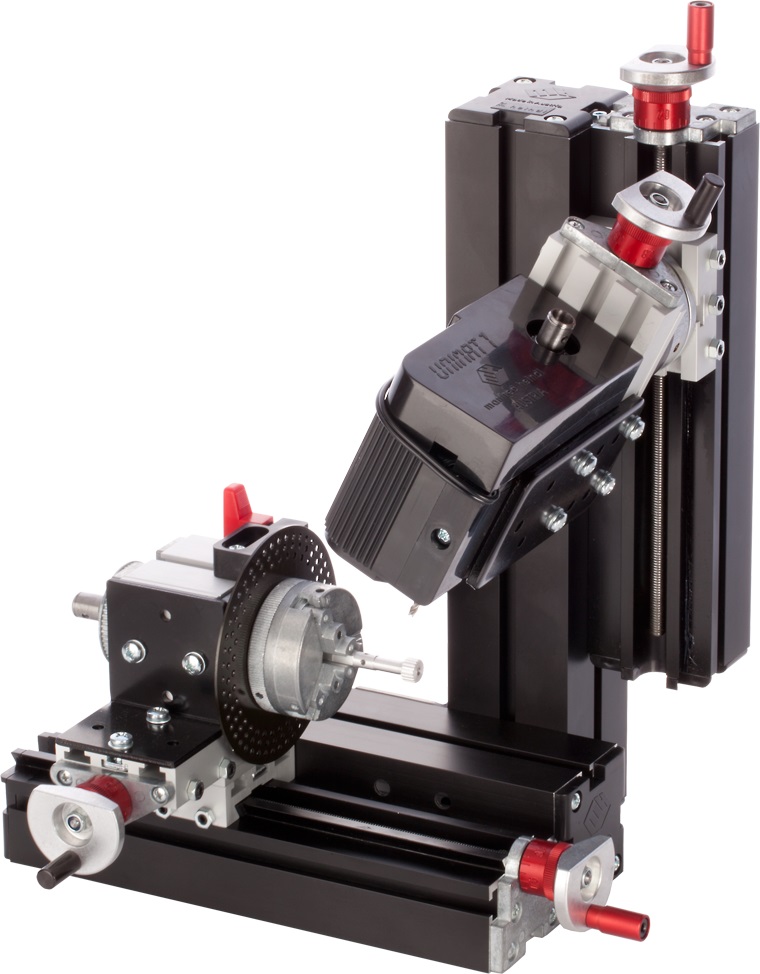

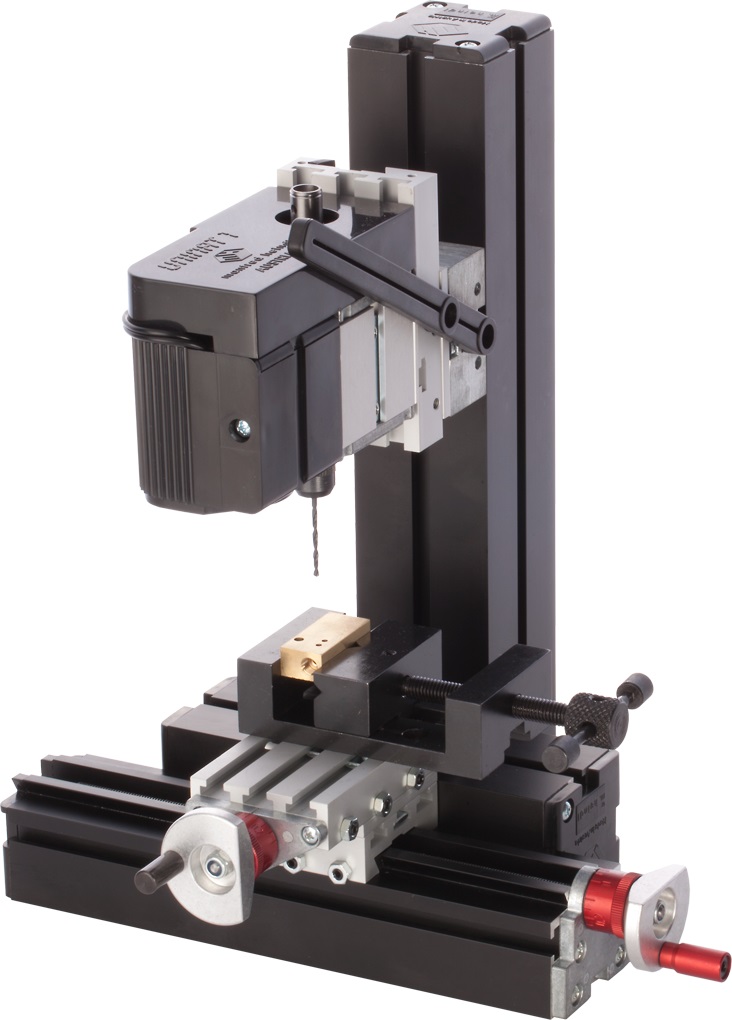

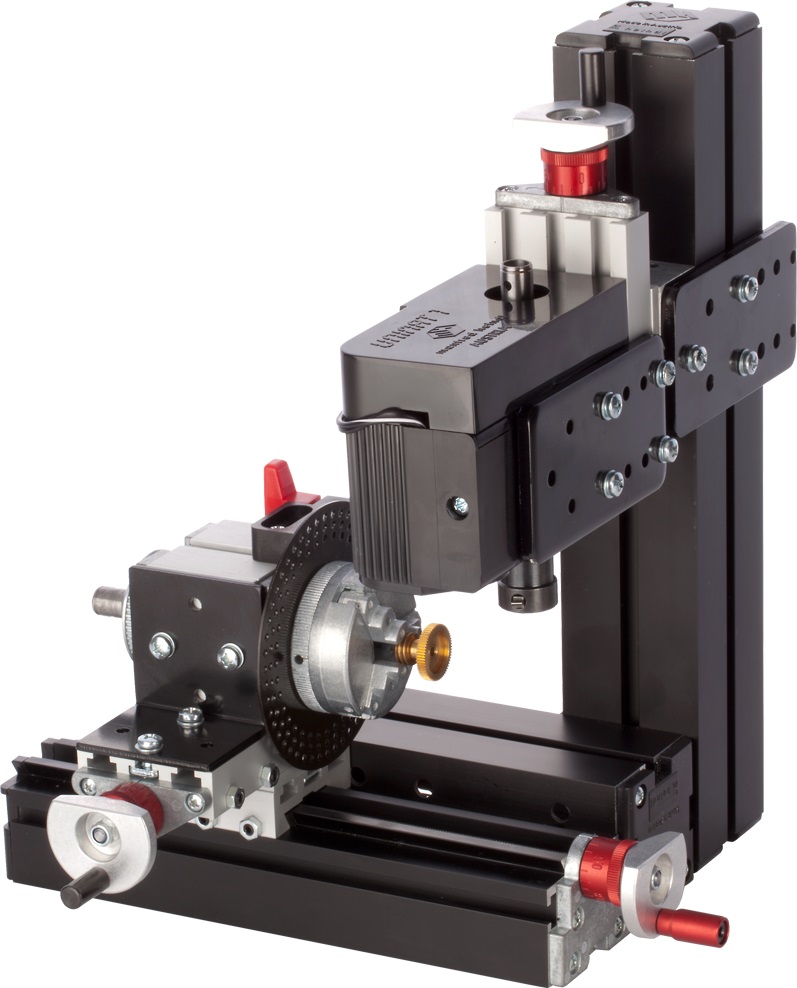

All this you can build with the kit:

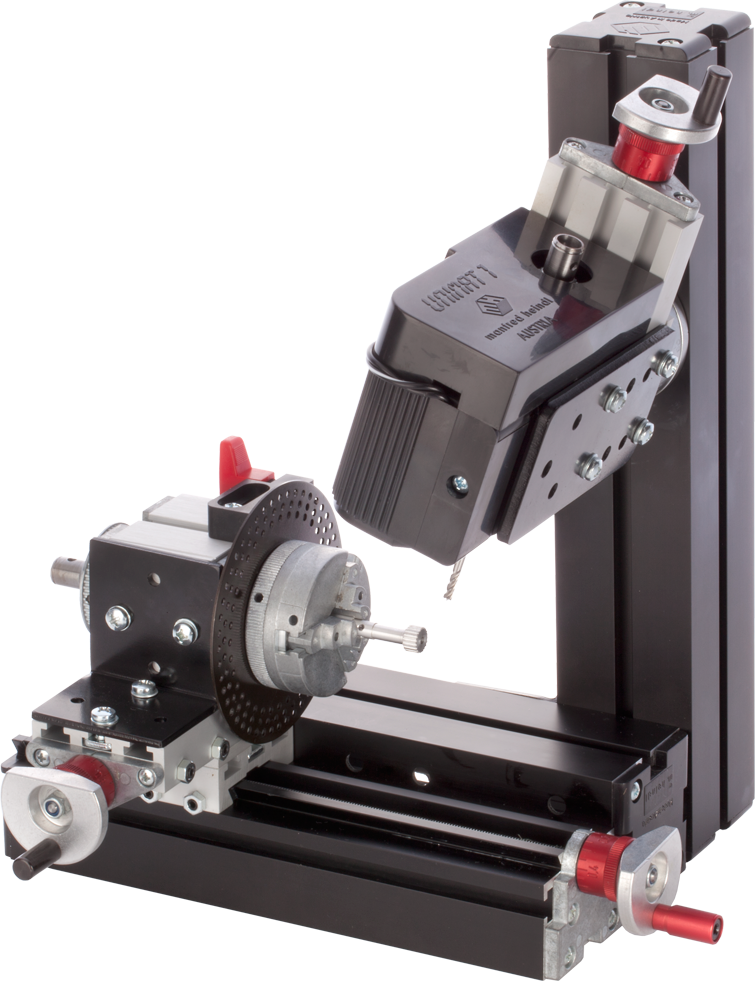

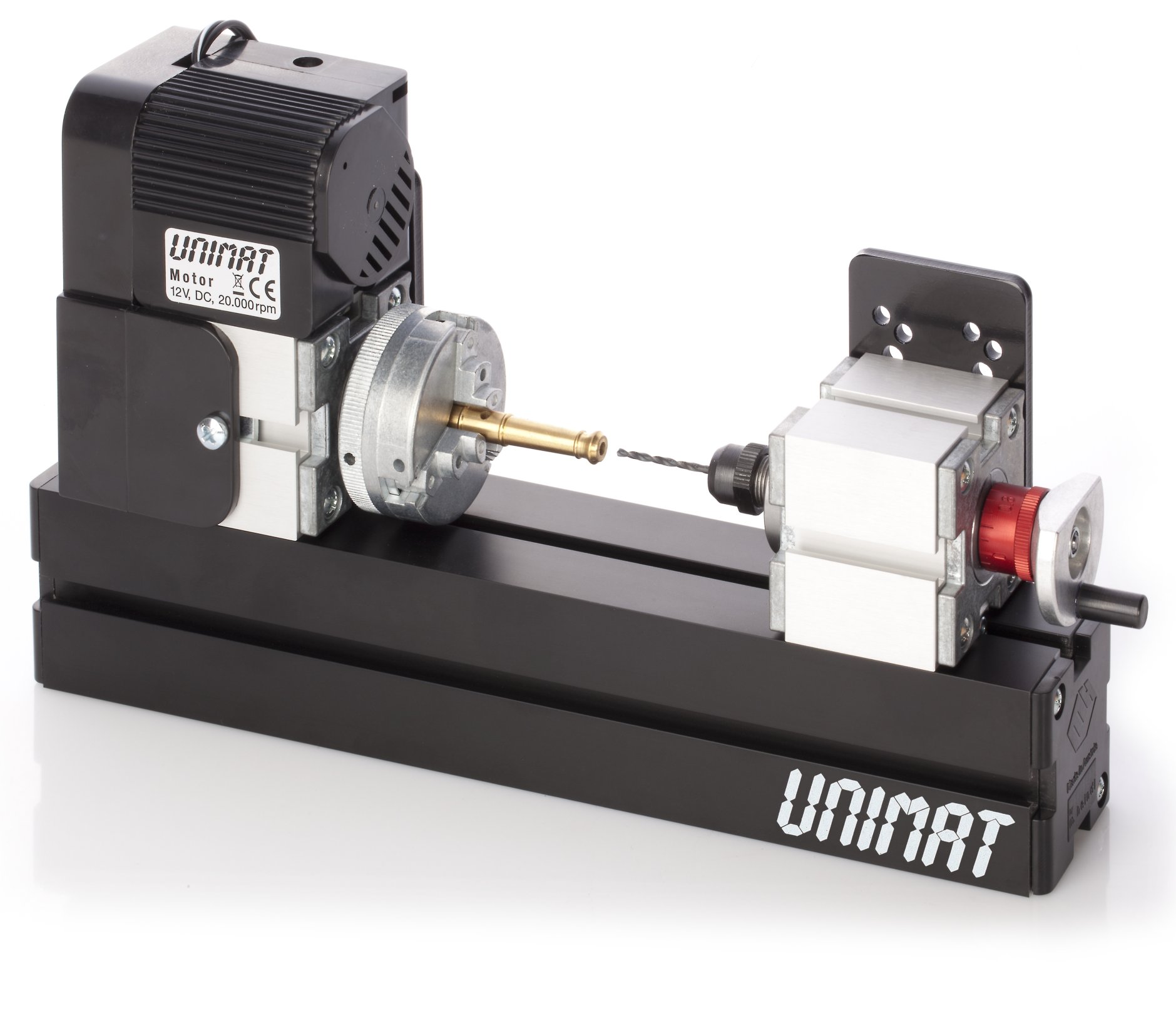

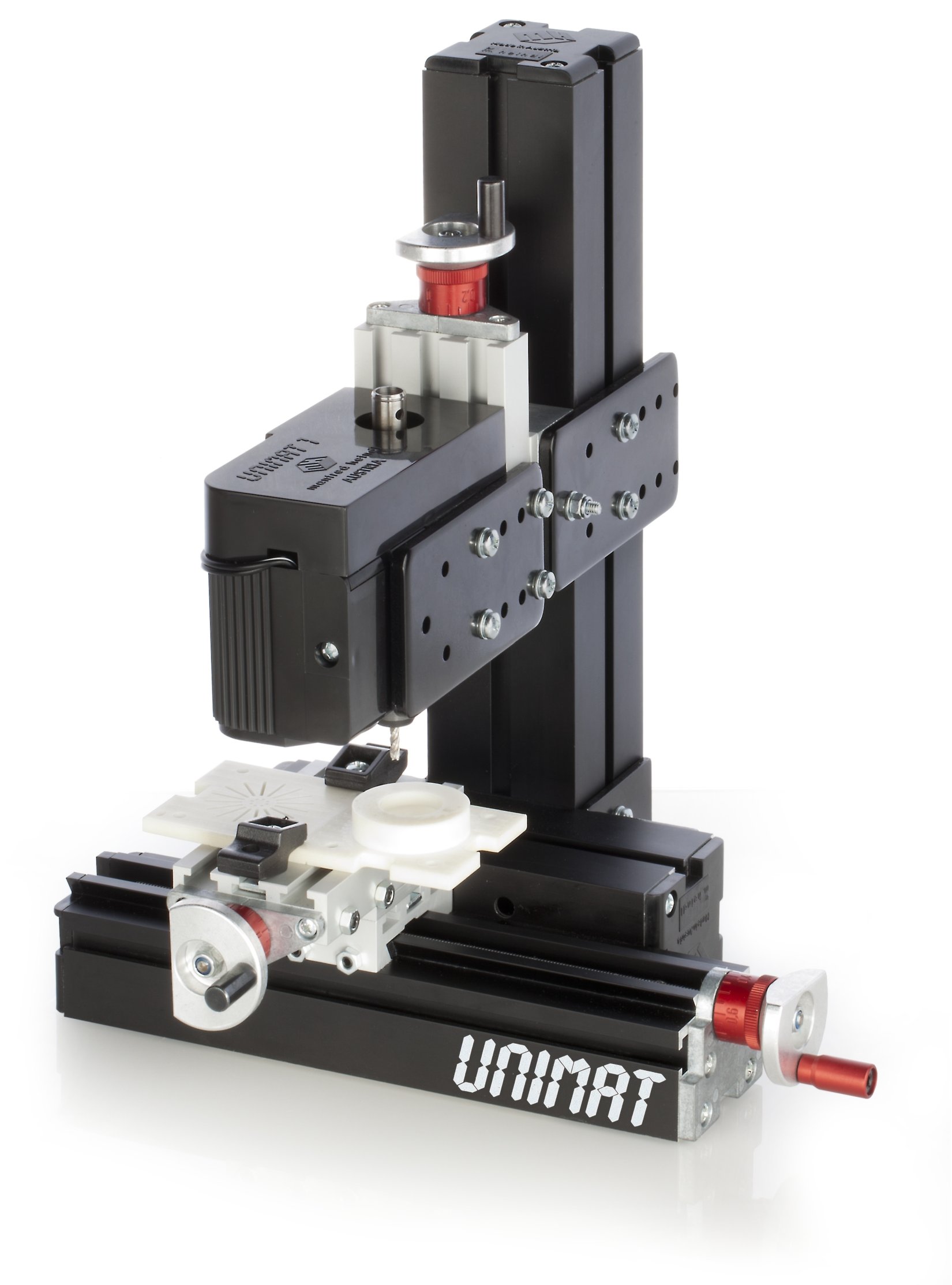

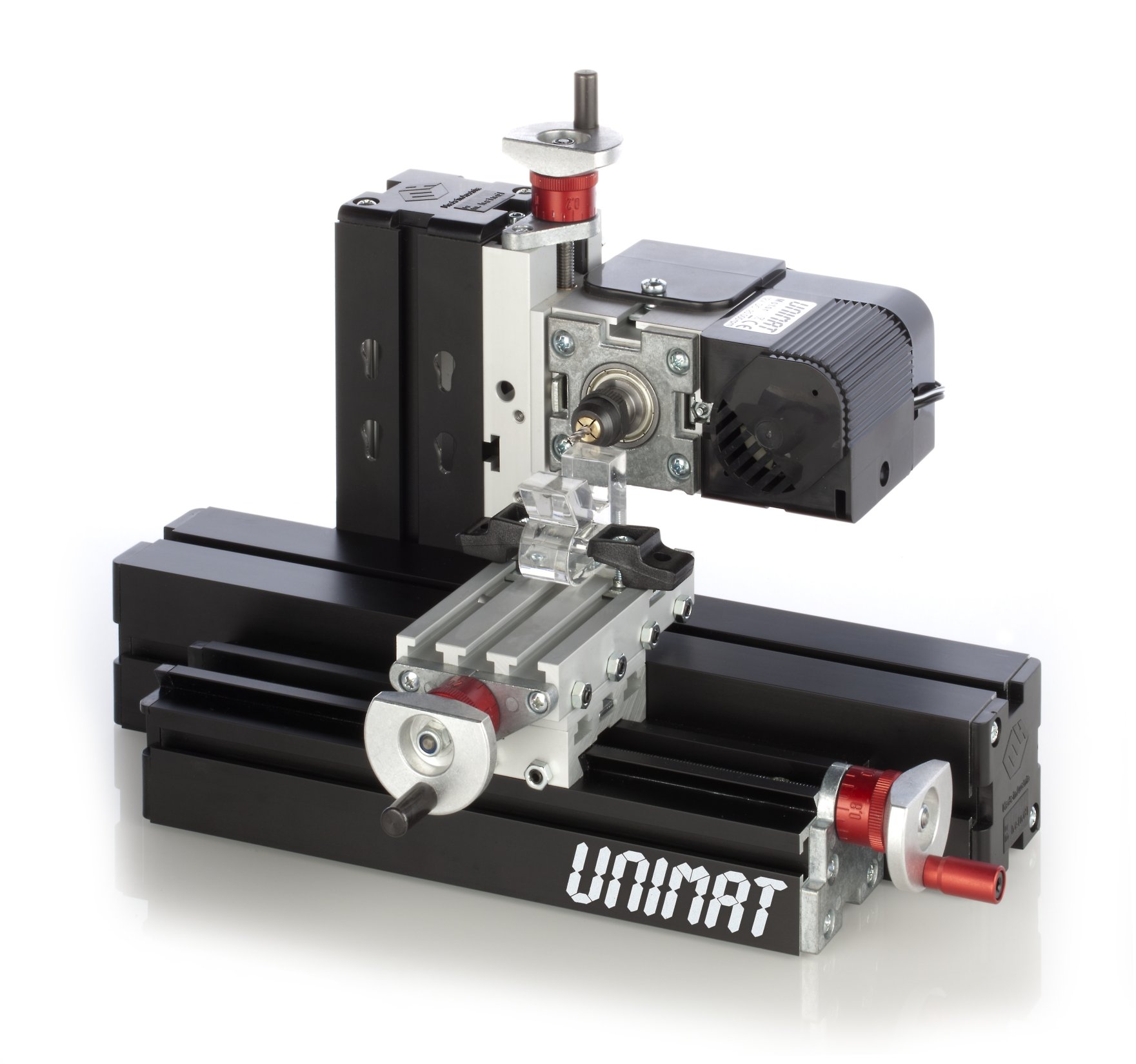

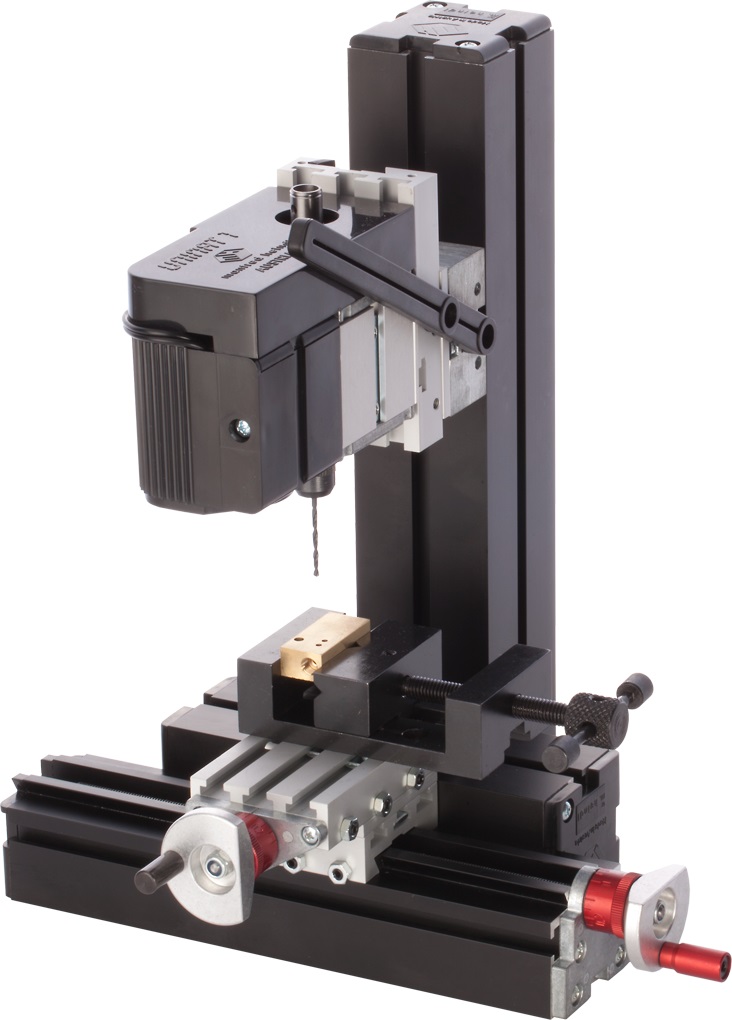

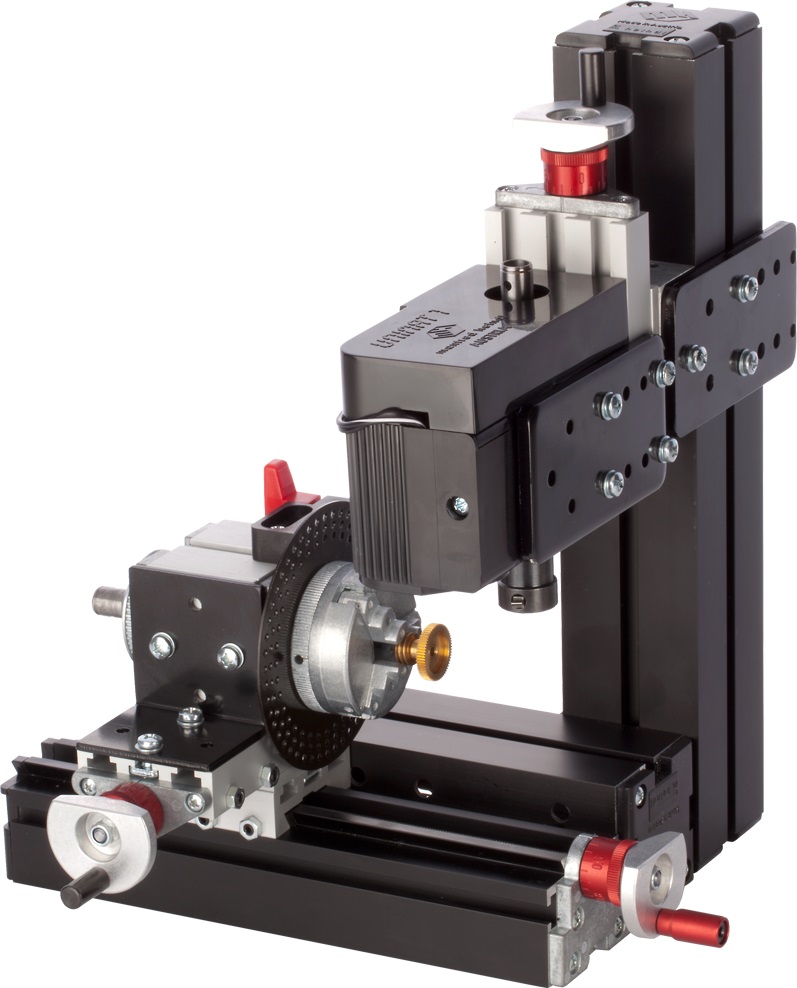

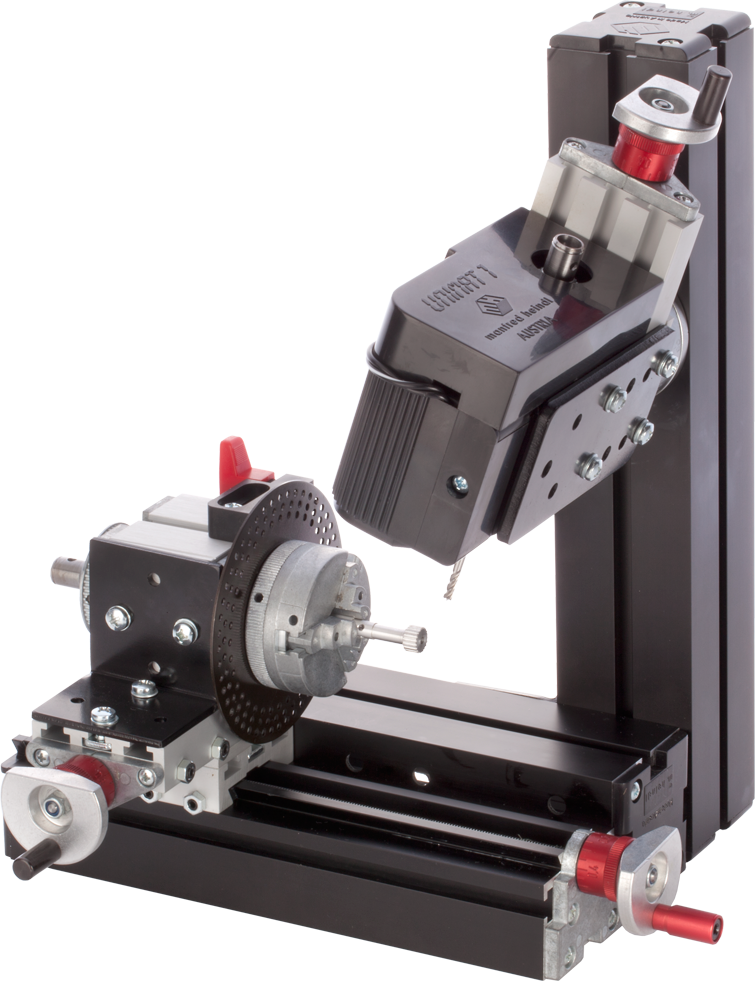

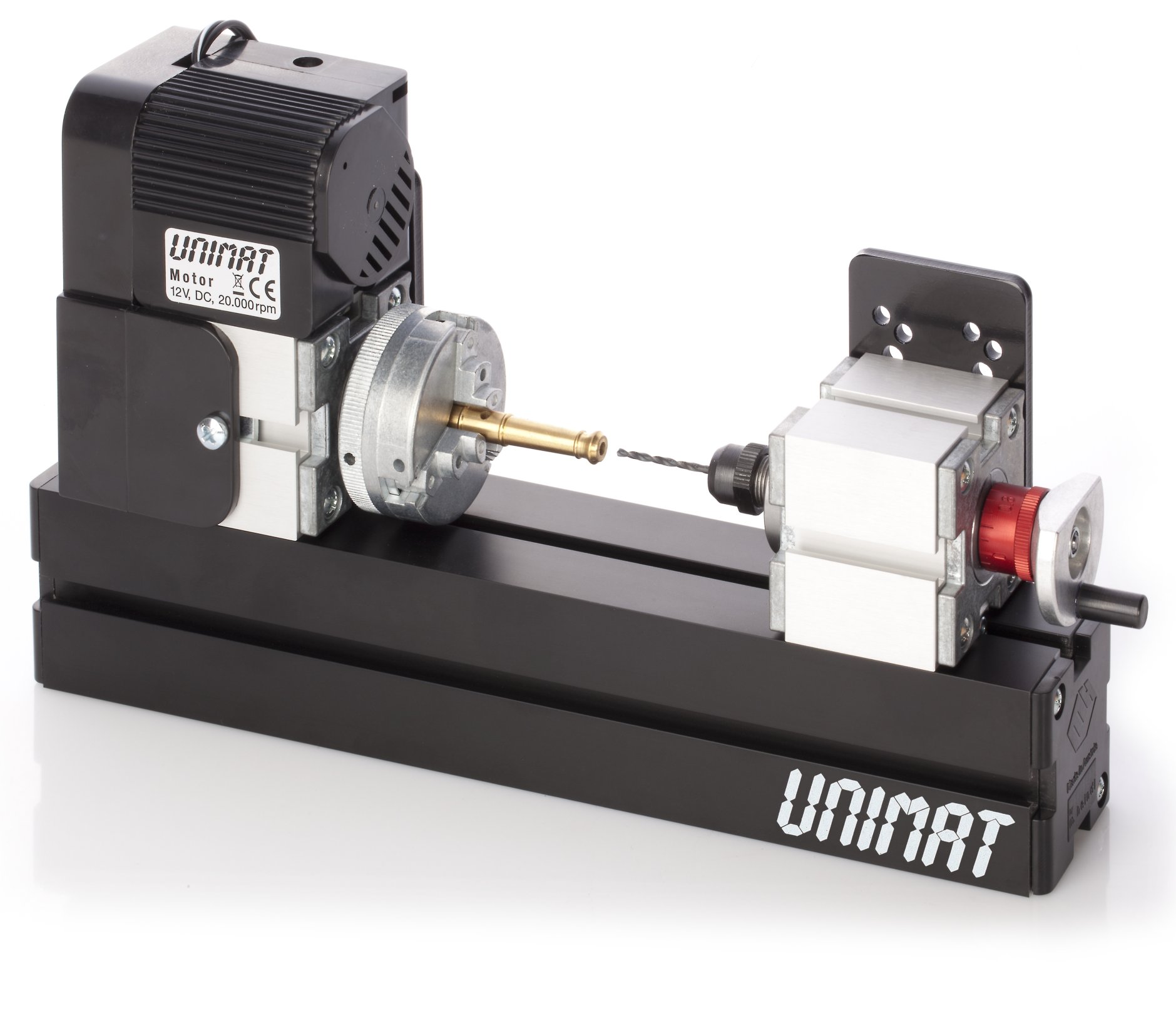

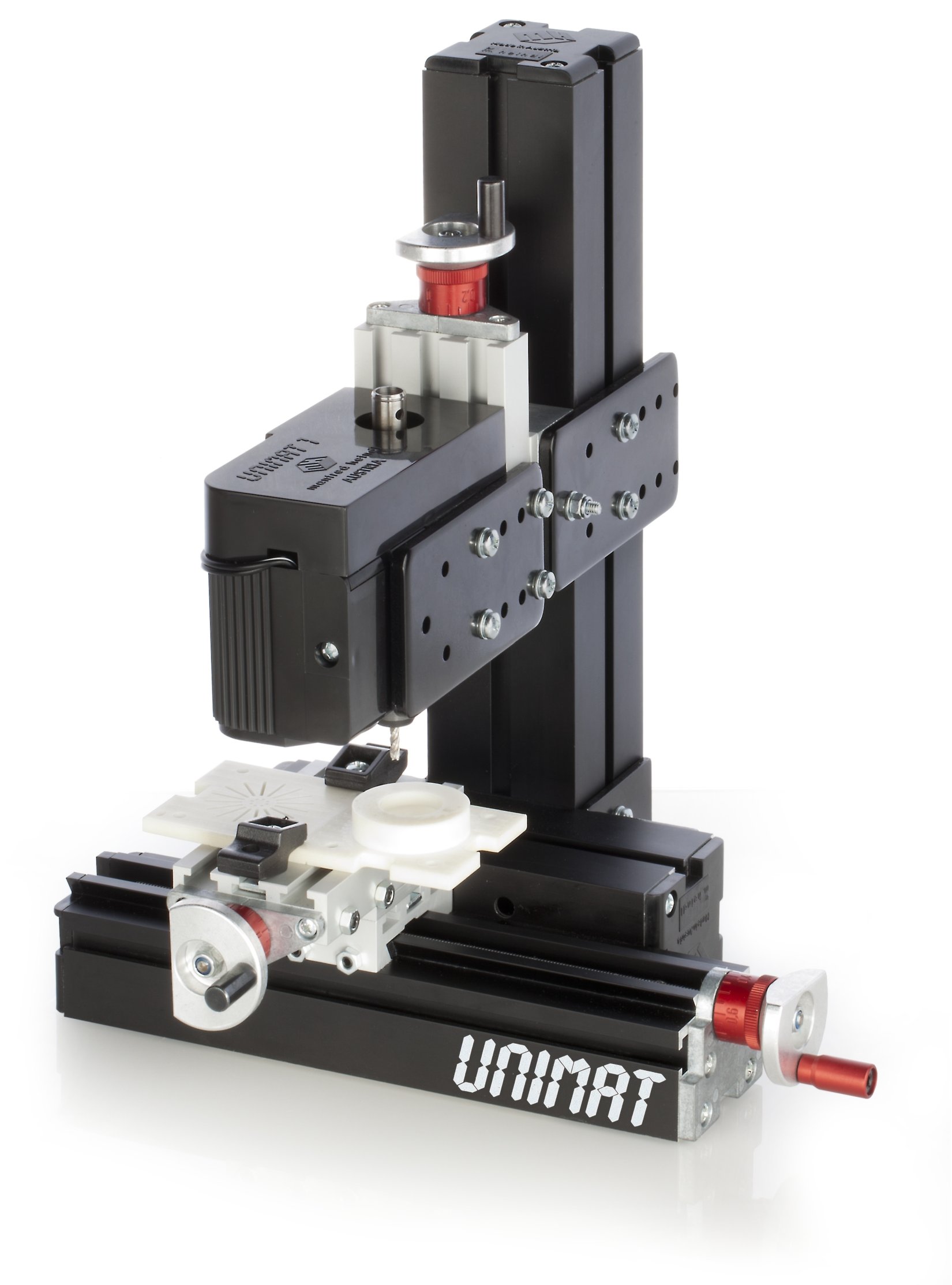

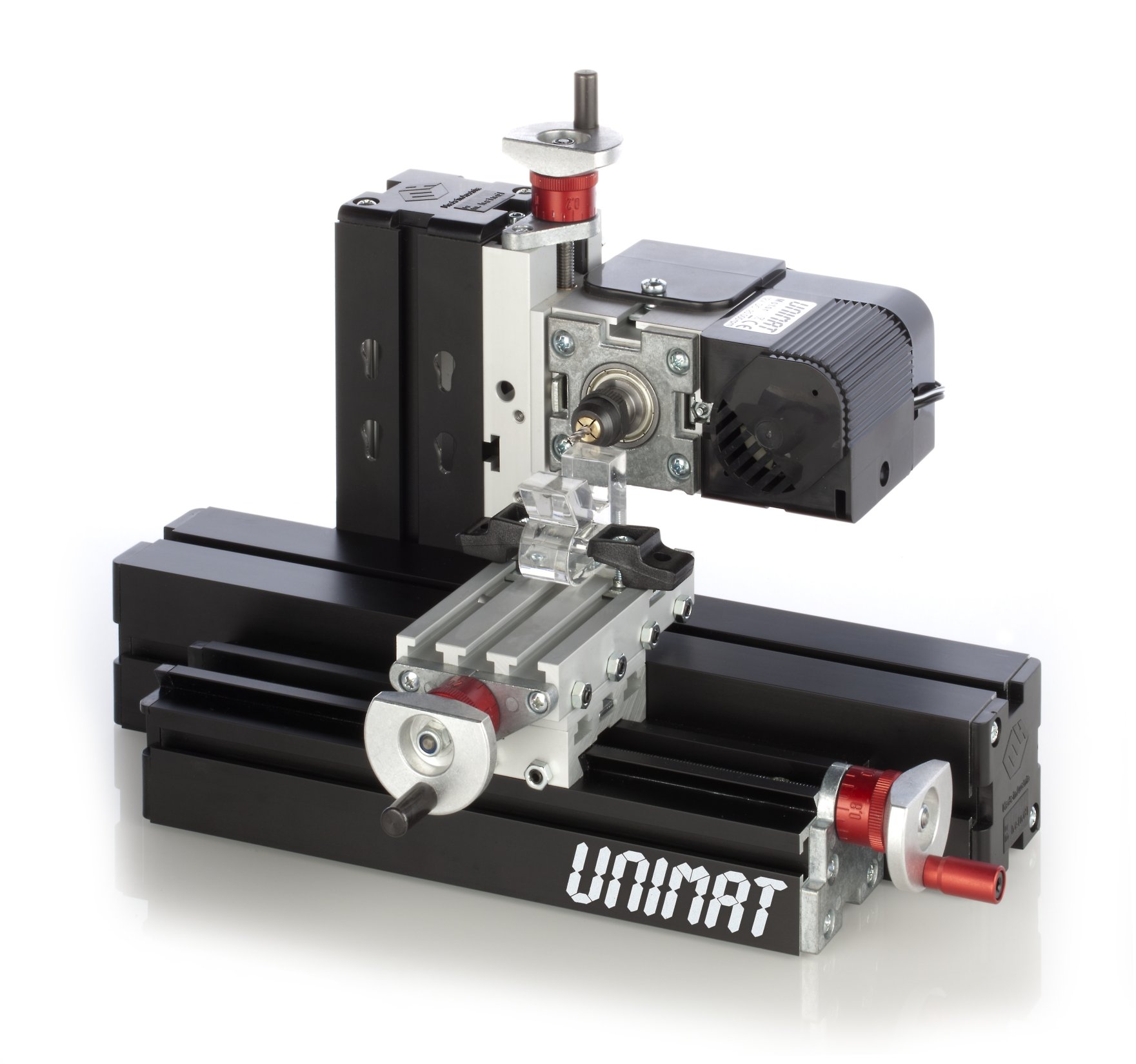

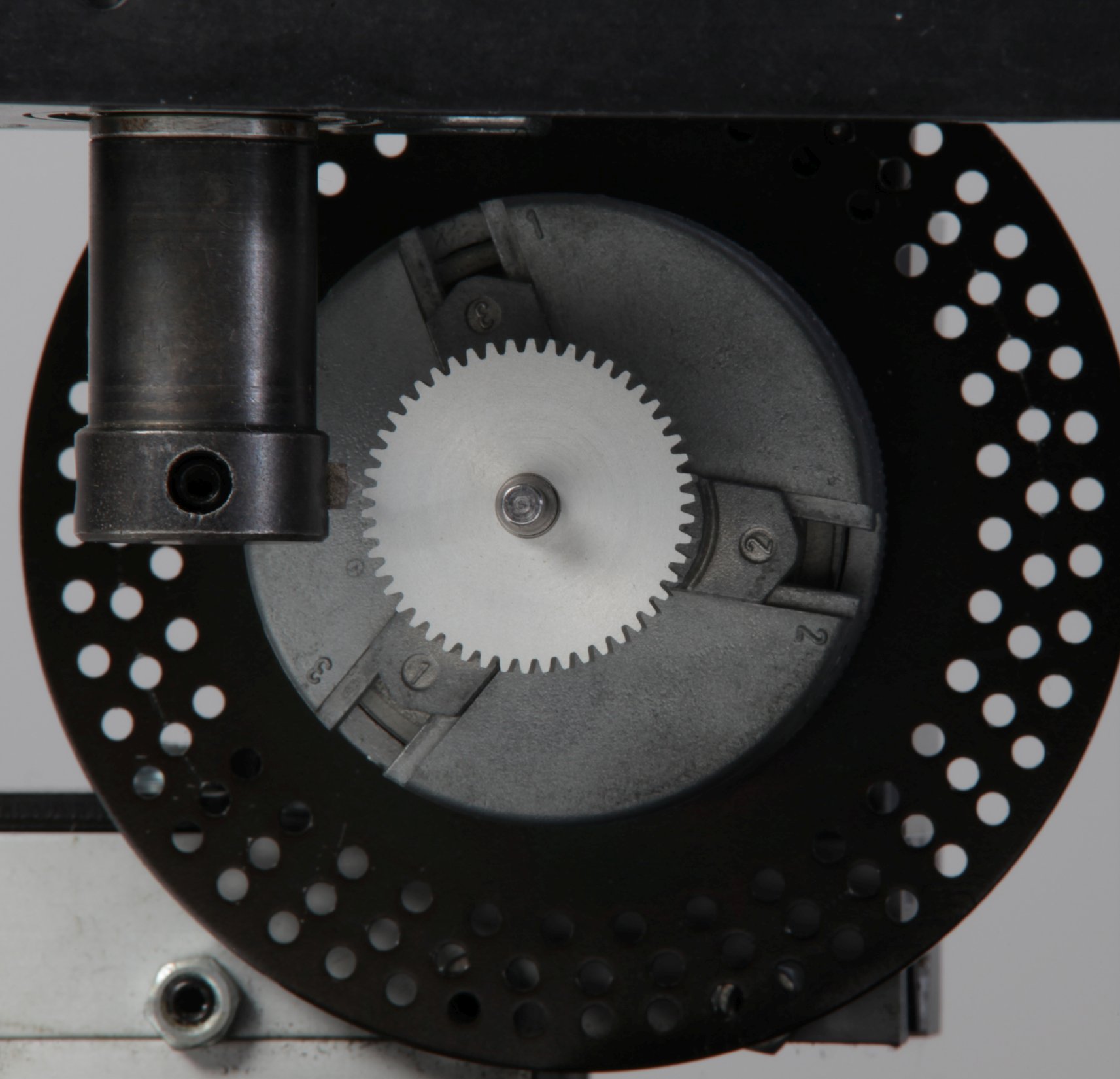

- Lathe - Horizontal milling machine - Vertical milling machine - Hand drill - Centering / Perlbohrmaschine - Hand grinder / disc grinder

Technical specifications:

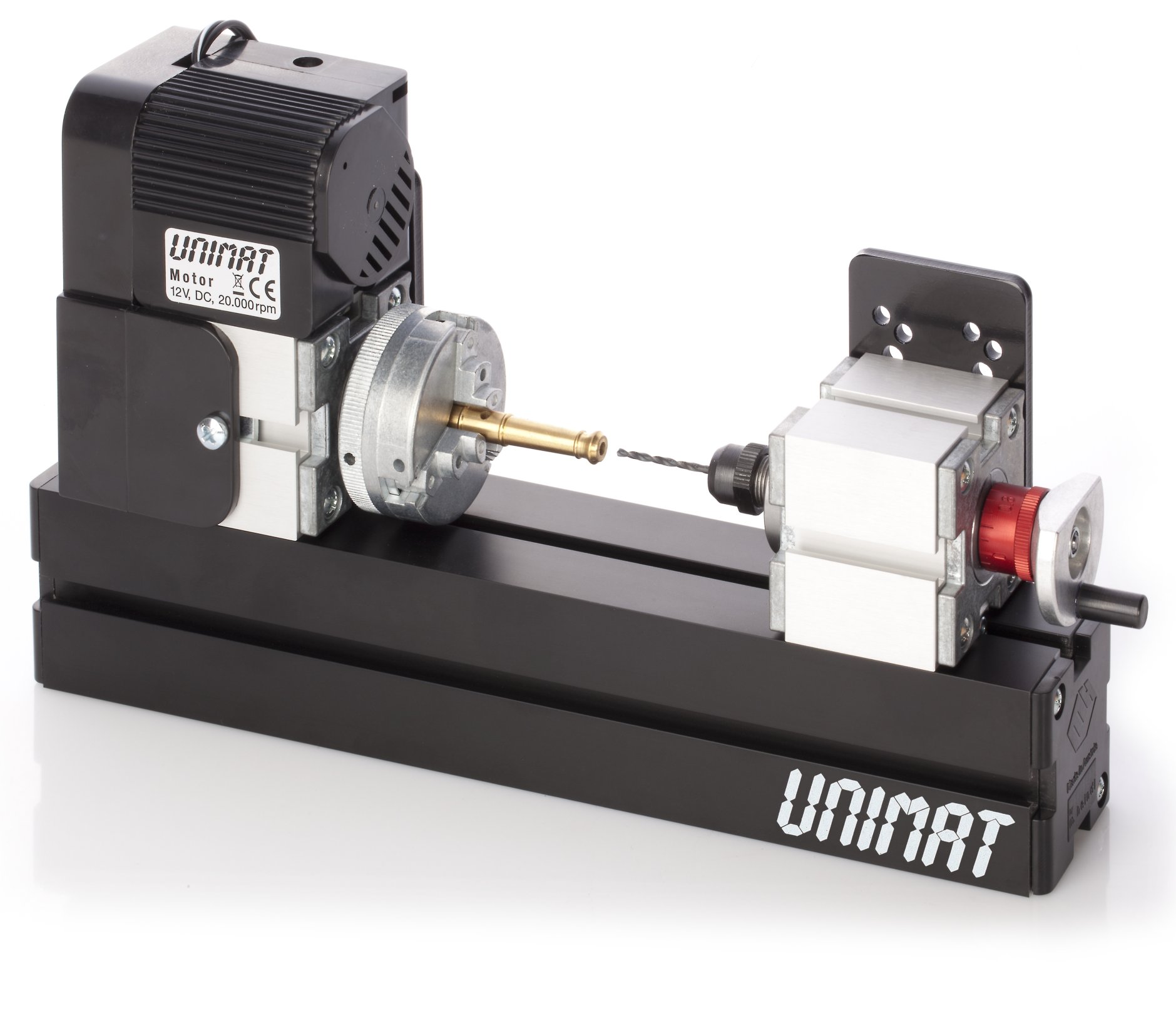

- Engine: 20,000 rpm

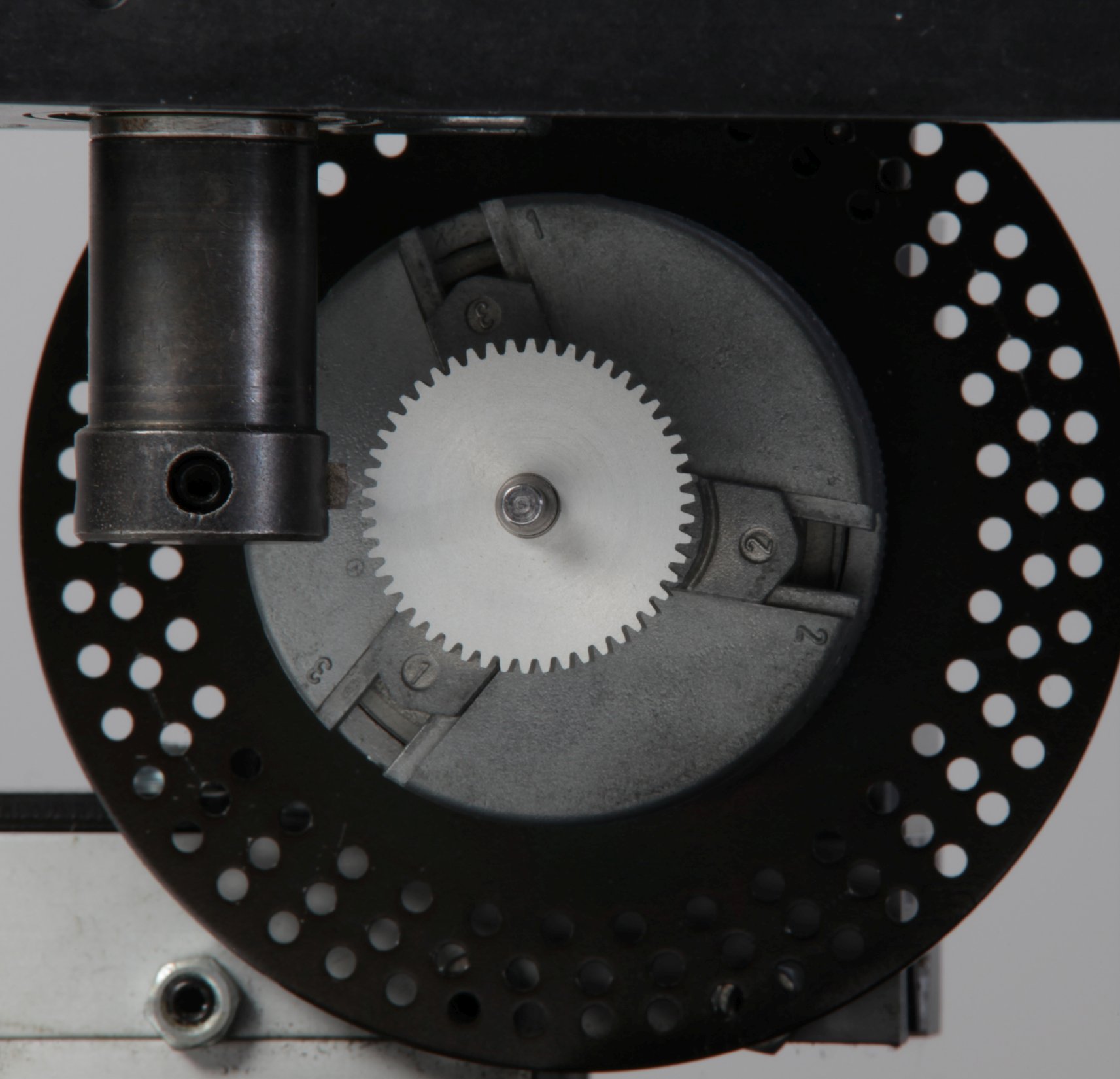

- Countershaft: M12 x 1.8mm bore

- Slide: 2 cross slides (32mm) - 1 longitudinal slide (145mm), spindle pitch

- tailstock: M12 x 1.30 mm quill stroke

- Power supply: 110-240V / 50-60Hz, 12V DC, 2A

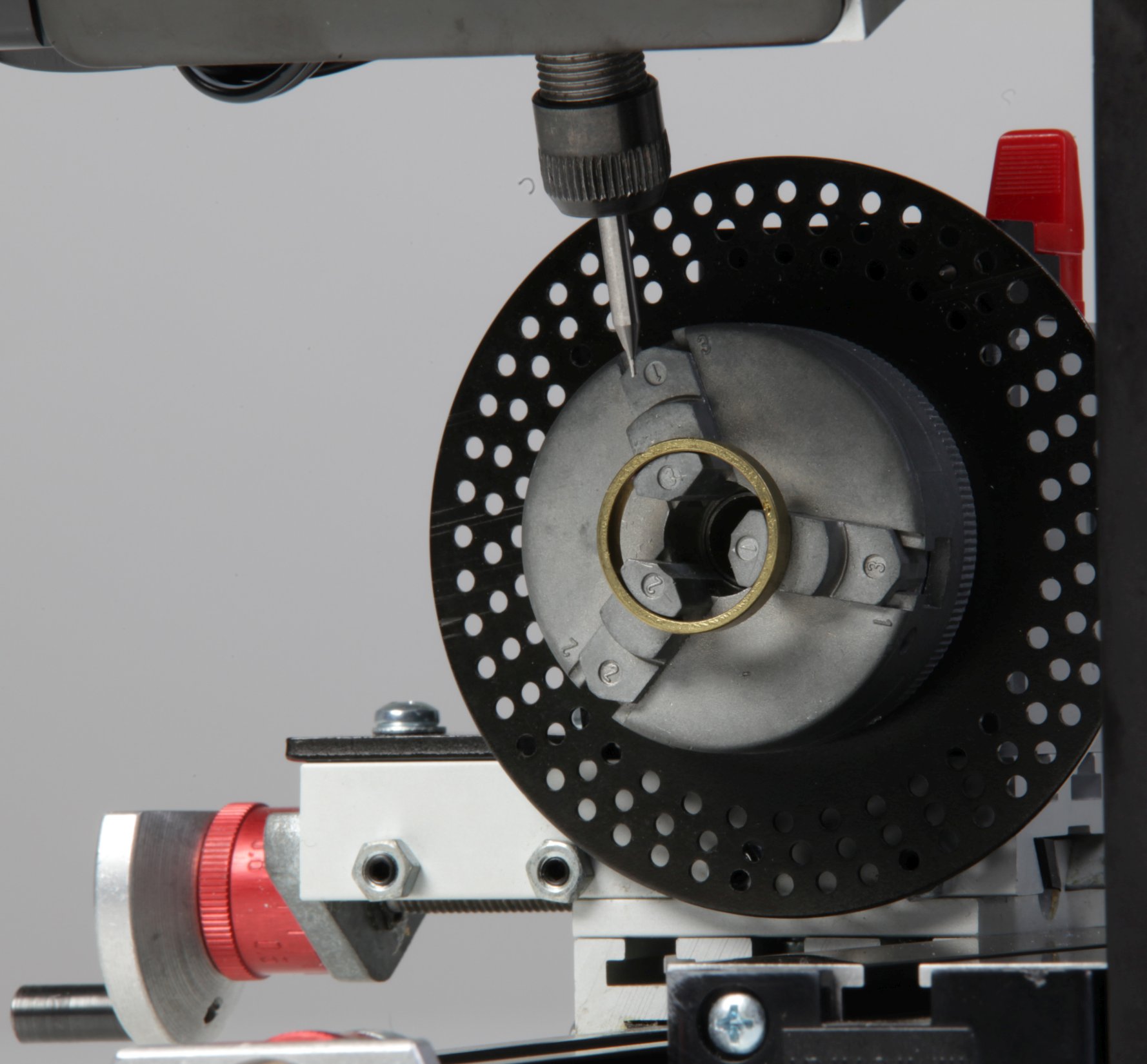

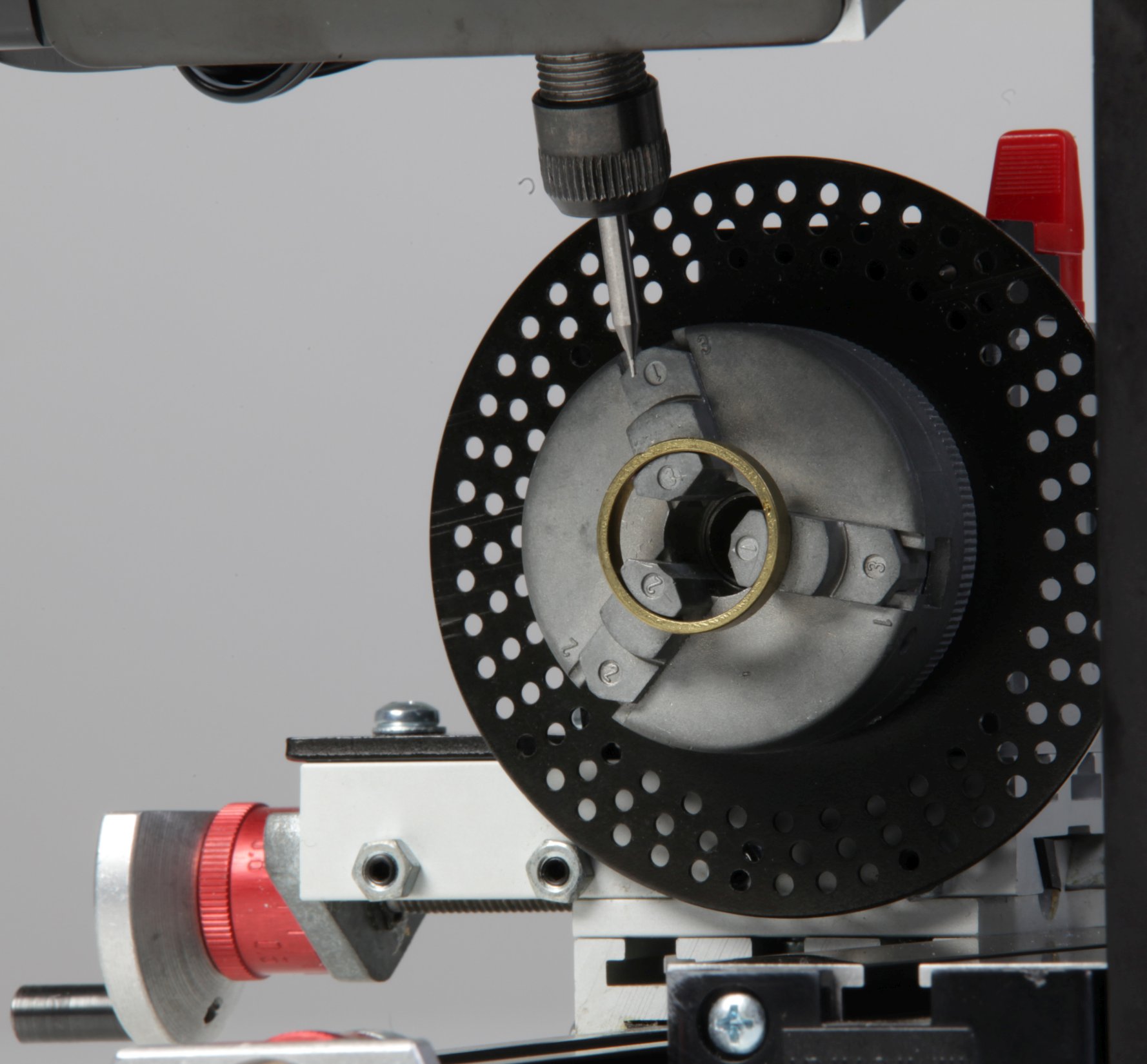

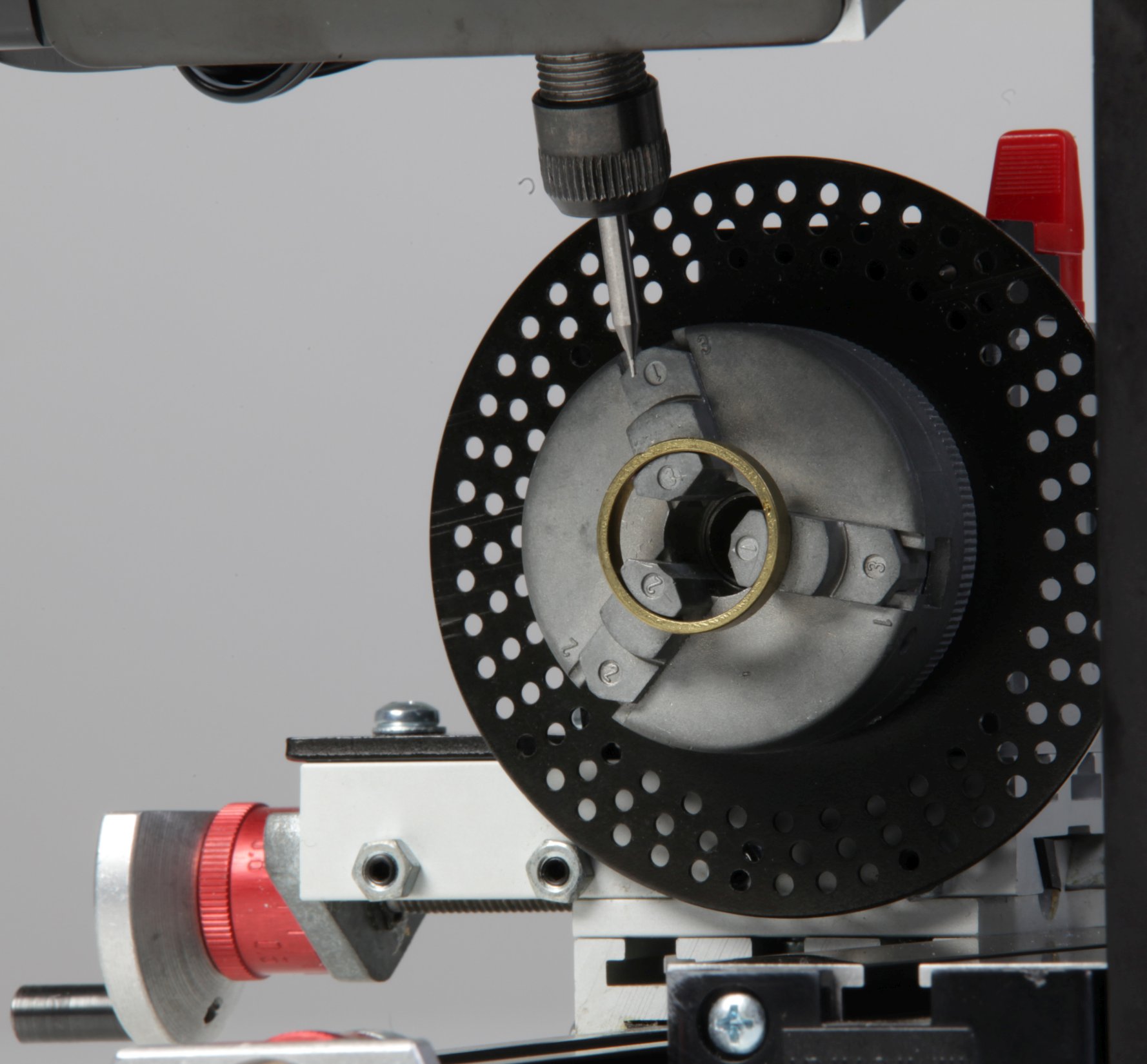

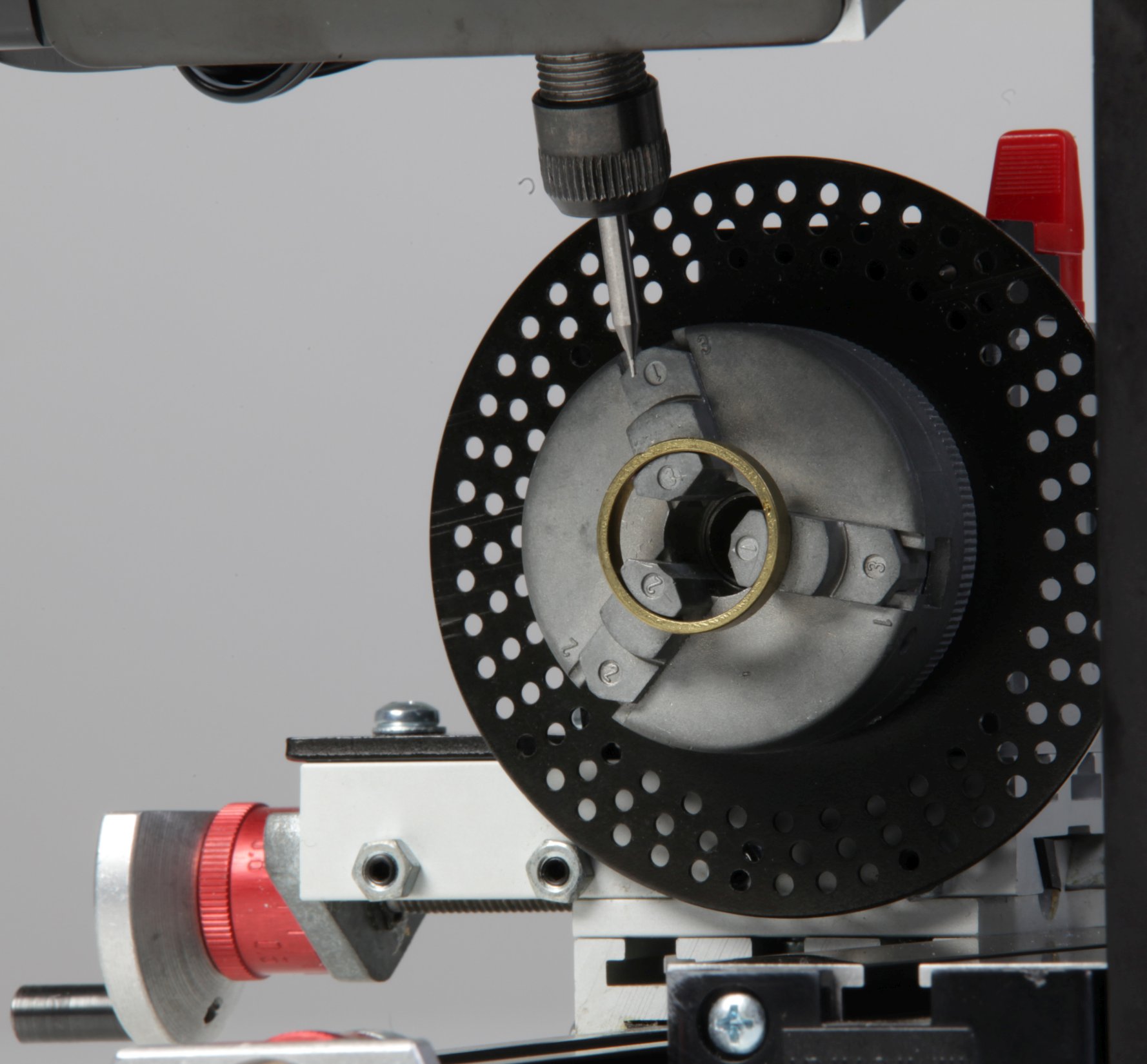

Zentrierbohrmaschine:

Drills from 1 to 6mm can be clamped to the tailstock and guided precisely over the quill path of 30mm. The 0.05mm scaled handwheel allows precise definition of the drilling depth!

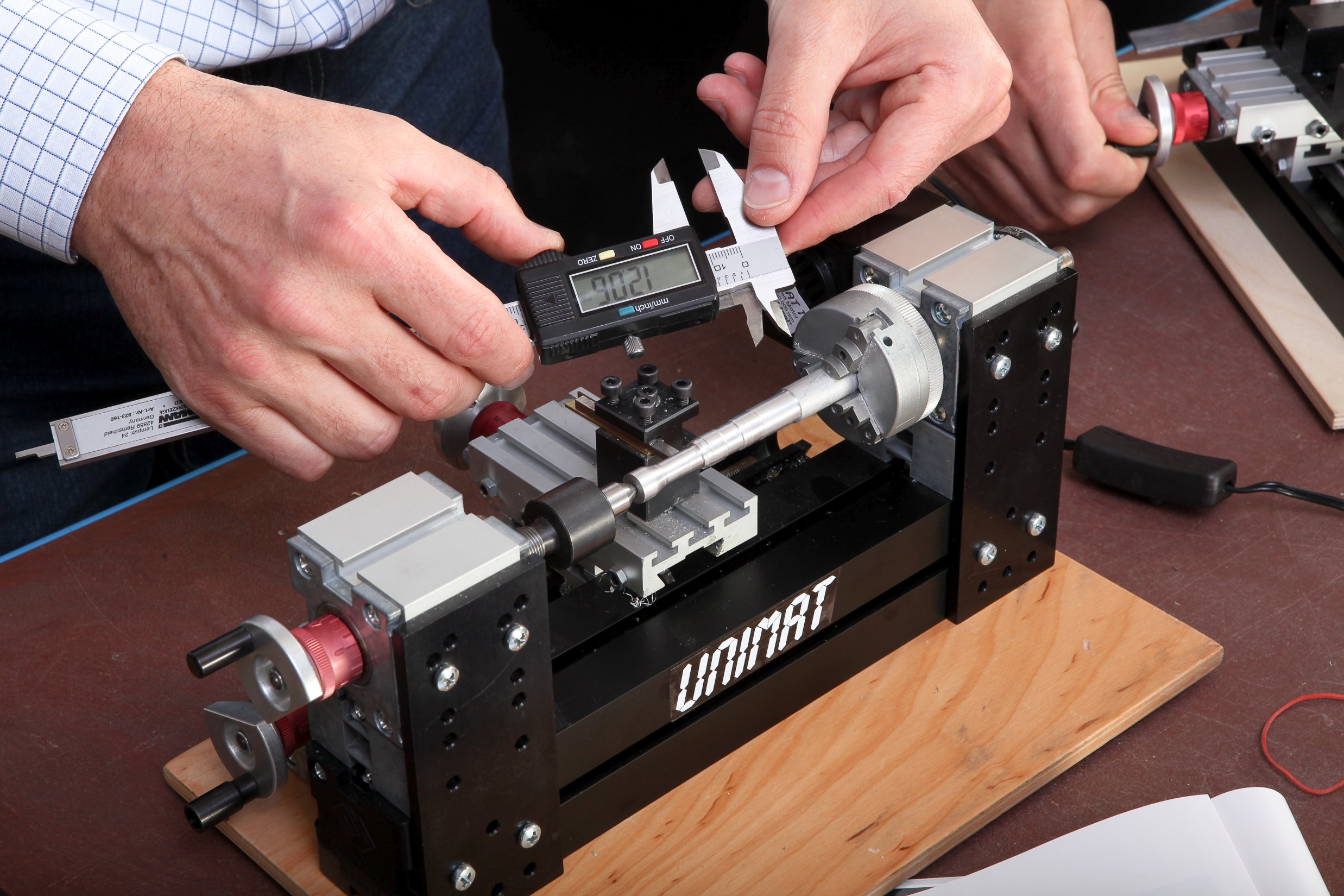

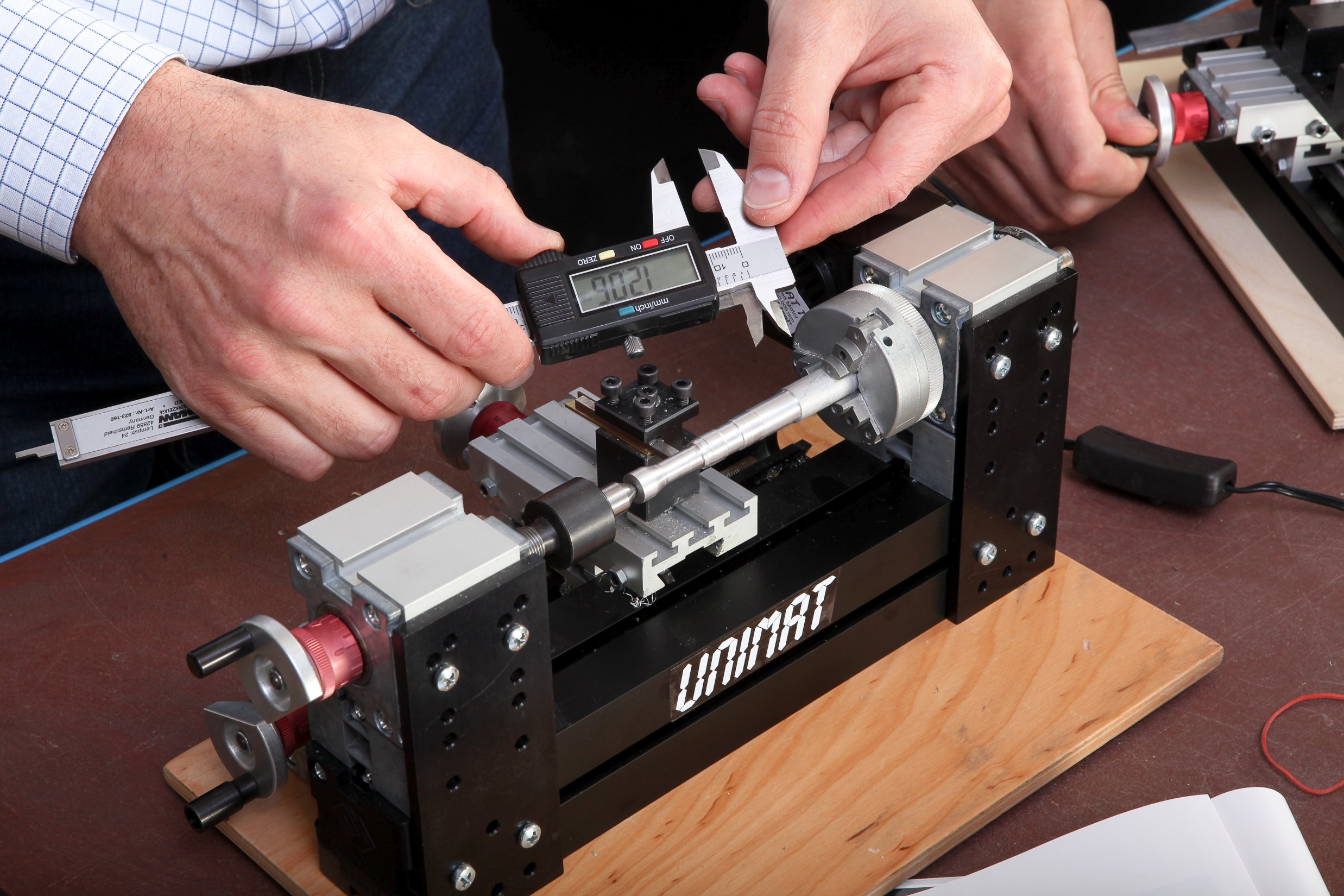

Lathe:

With a center height of 50mm, a center distance of 90mm and multiple steel holders, aluminum, copper, brass and many other metals can be perfectly machined. With the 3-jaw chuck, workpieces up to Ø 56mm (65mm with external clamping) can be fixed. Travel: Z-axis 145mm, X-axis 32mm.

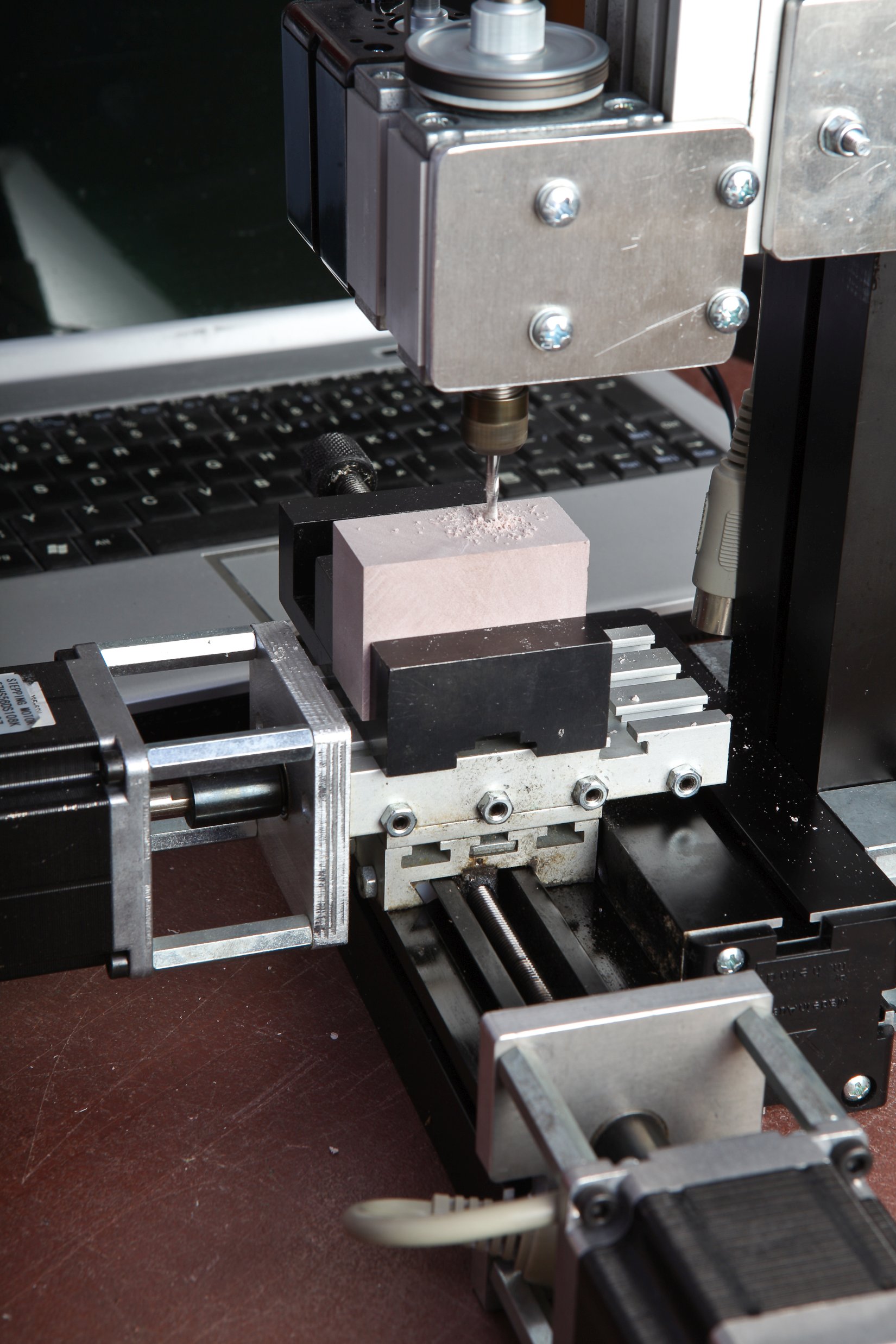

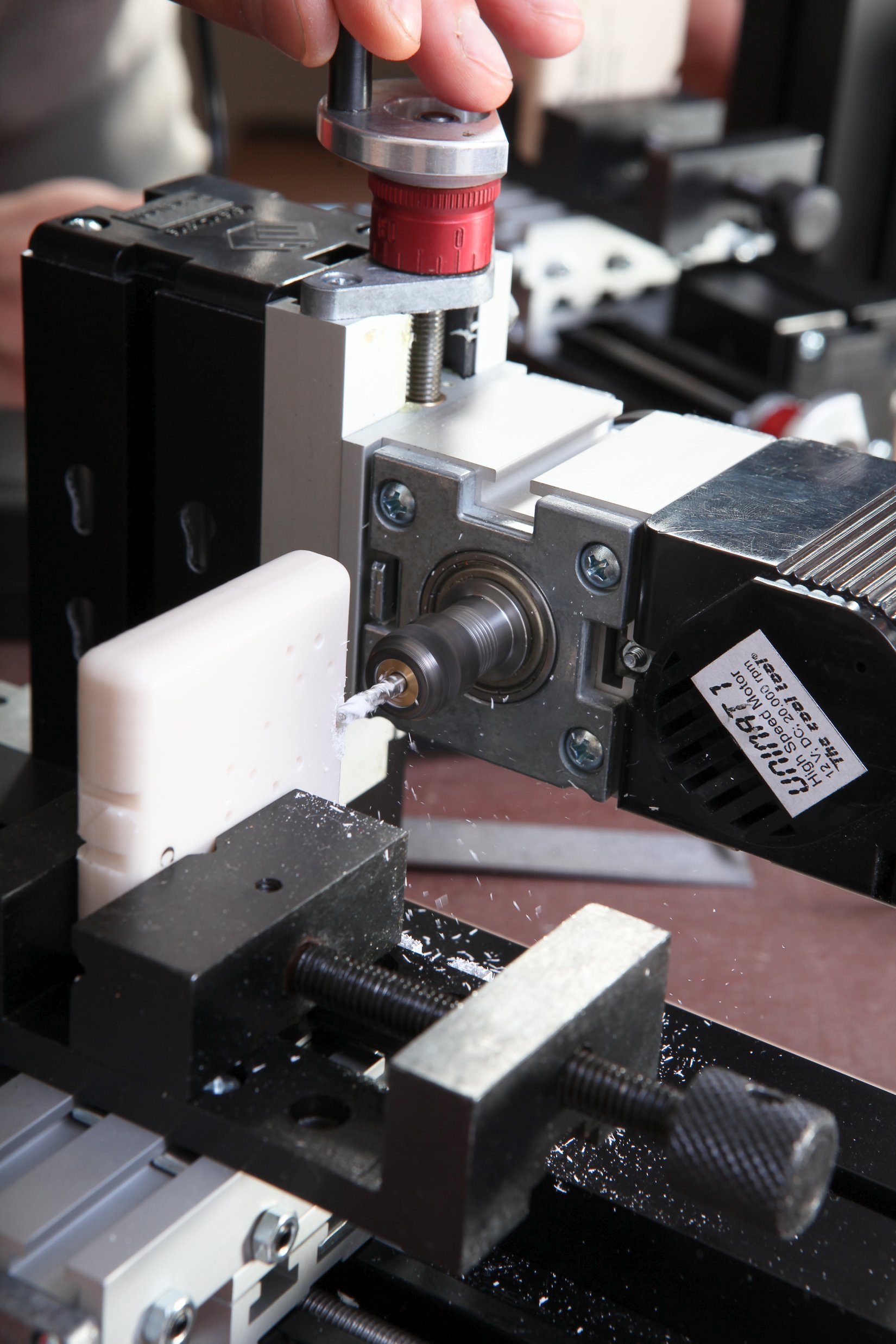

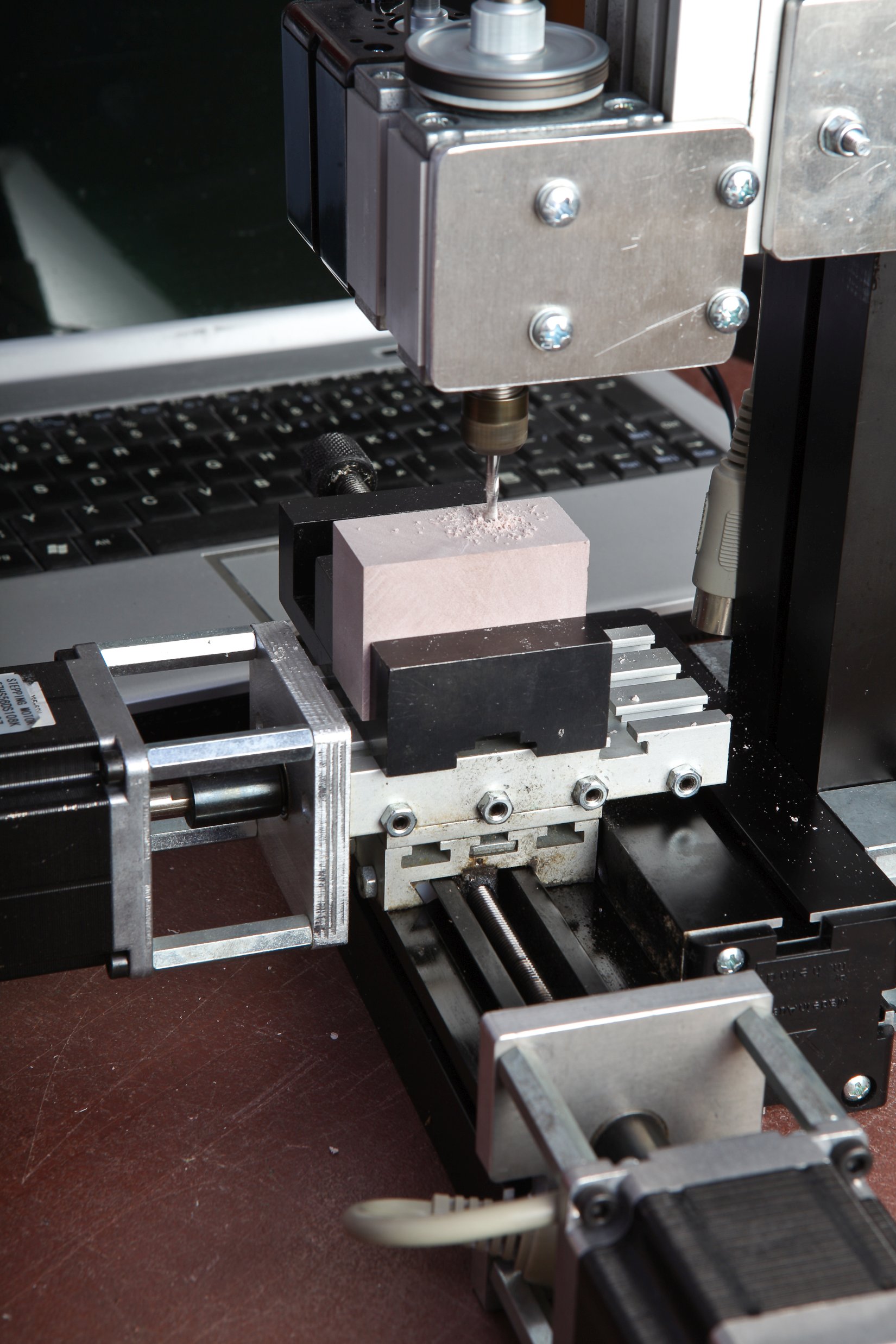

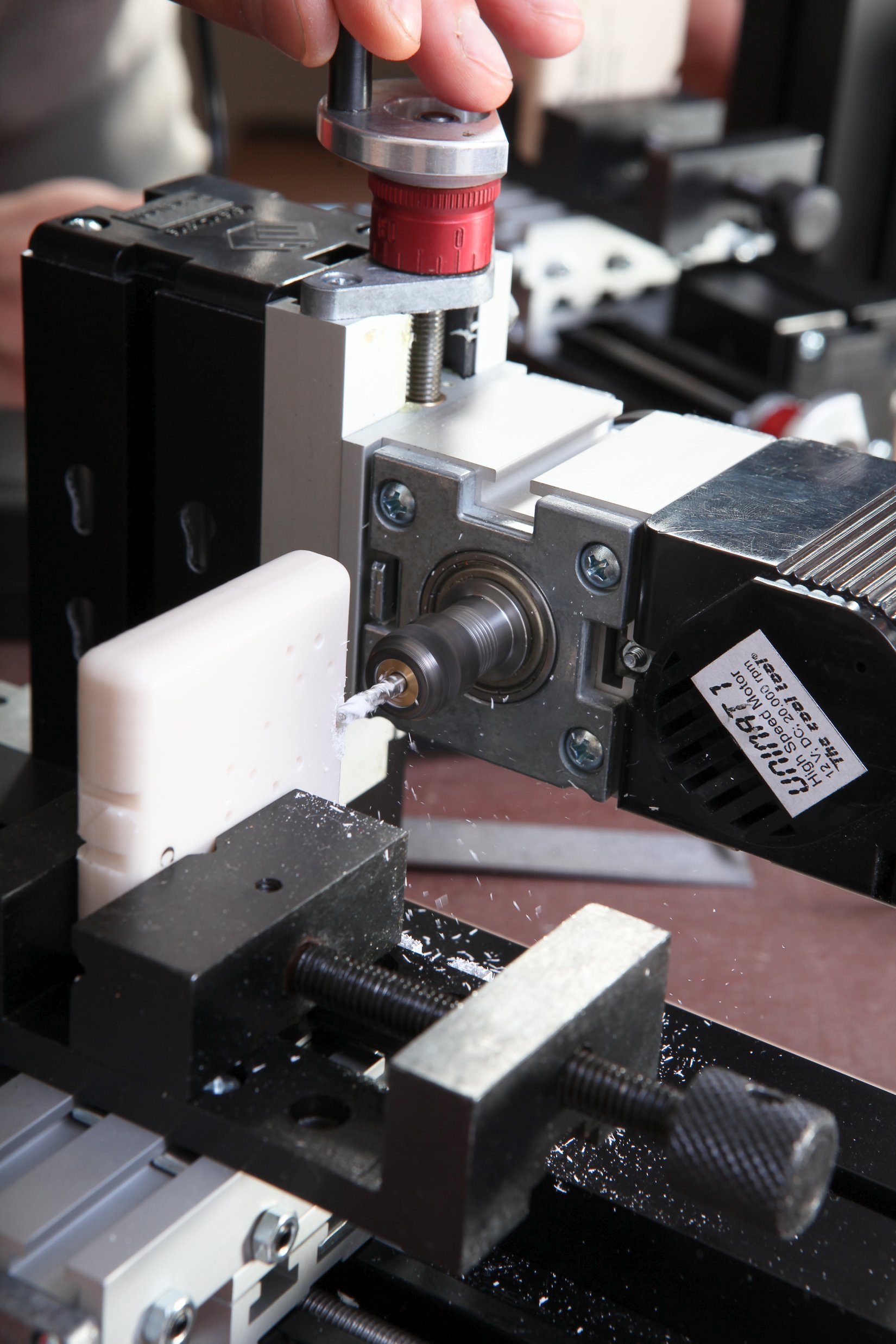

Horizontal Mill:

By using the three carriages, workpieces can be processed as desired in all levels. Cutter seat from 1 to 6mm shaft thickness.

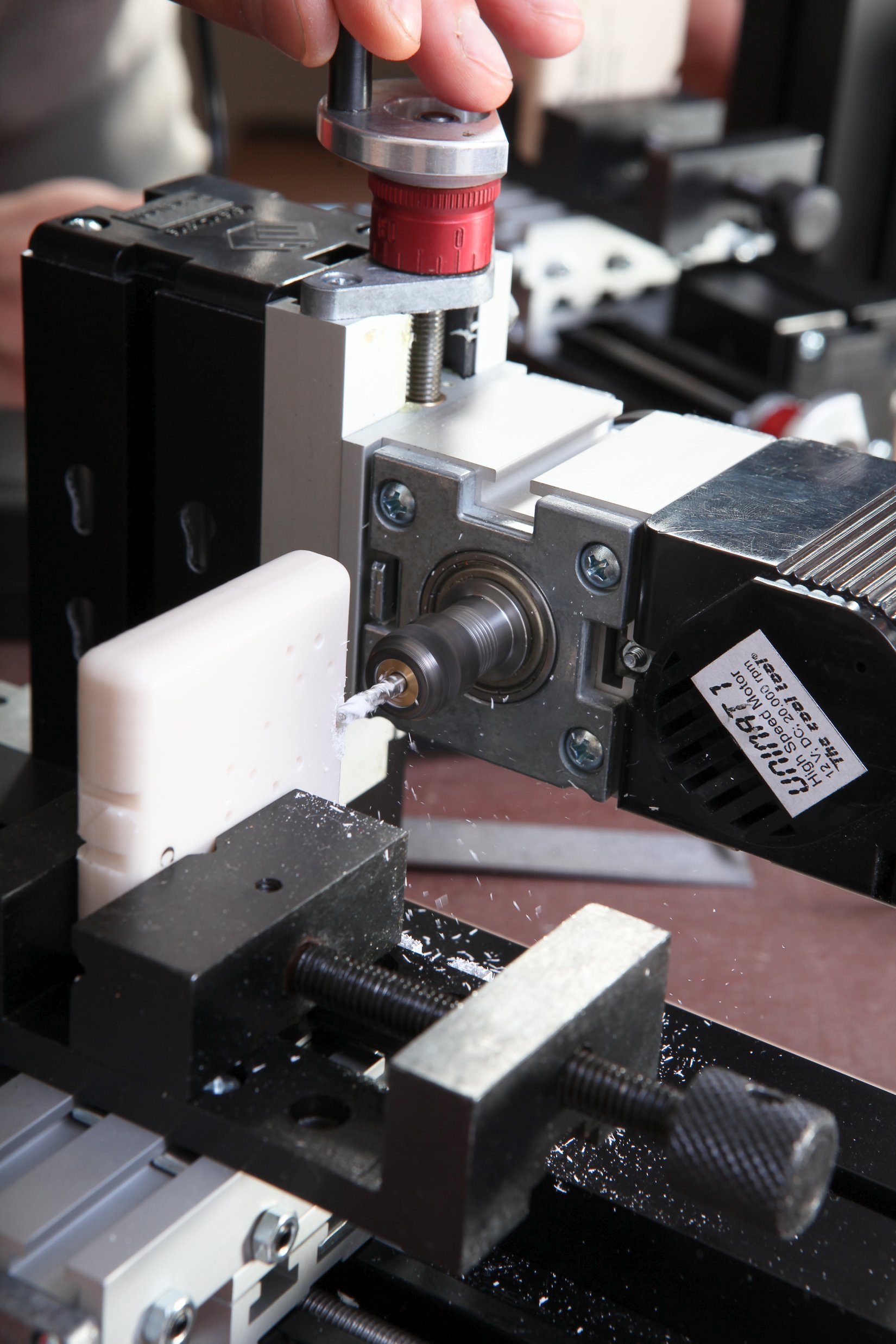

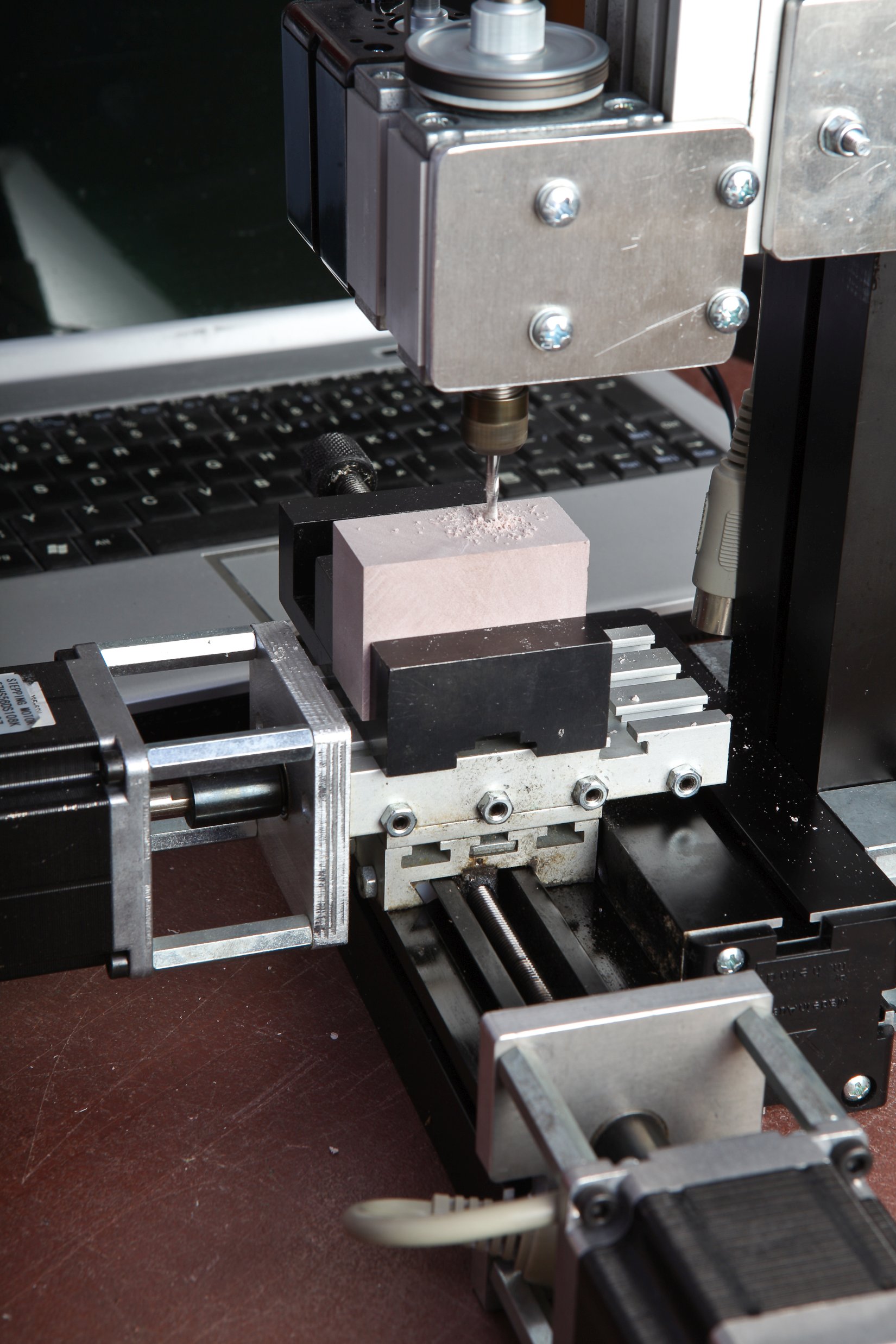

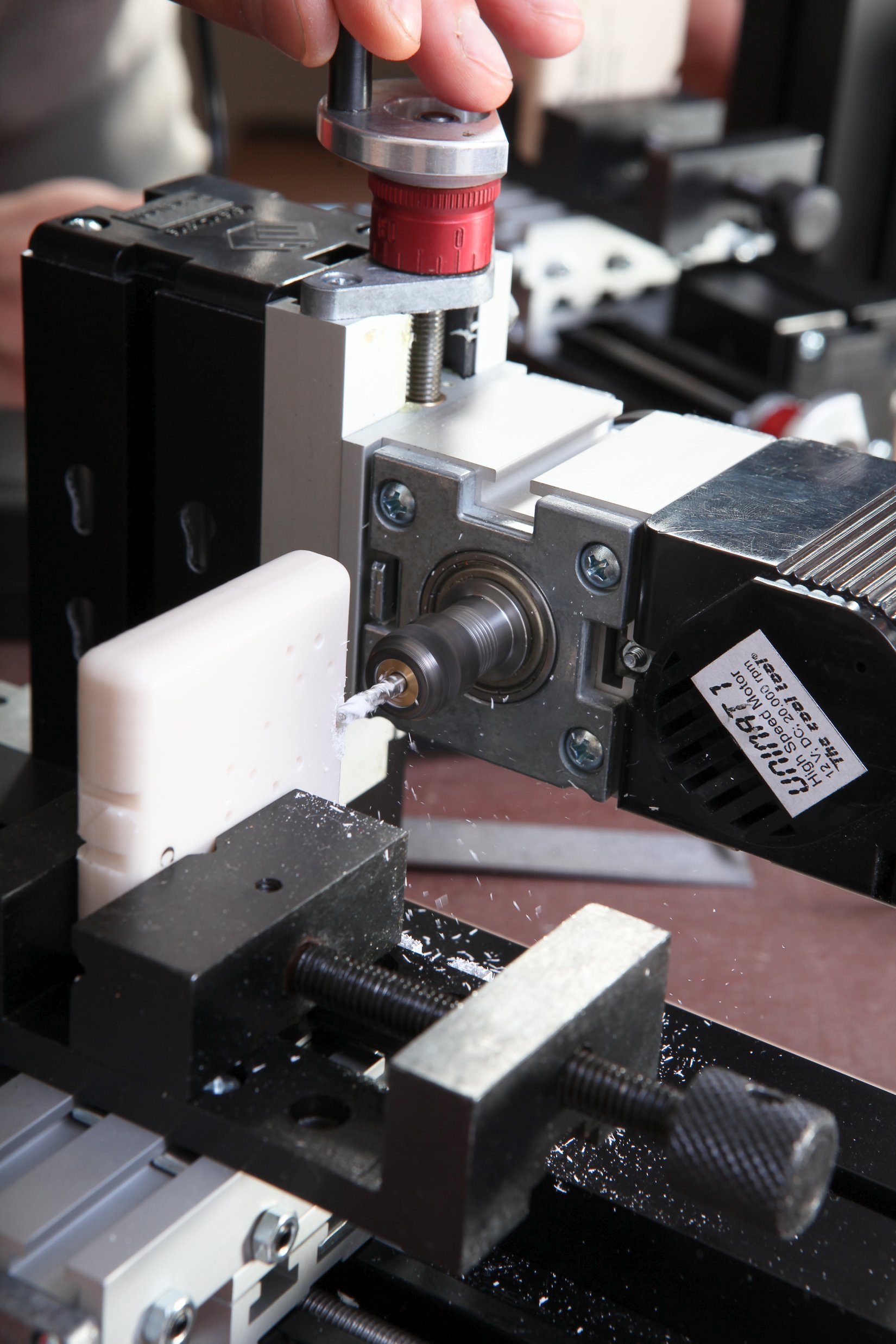

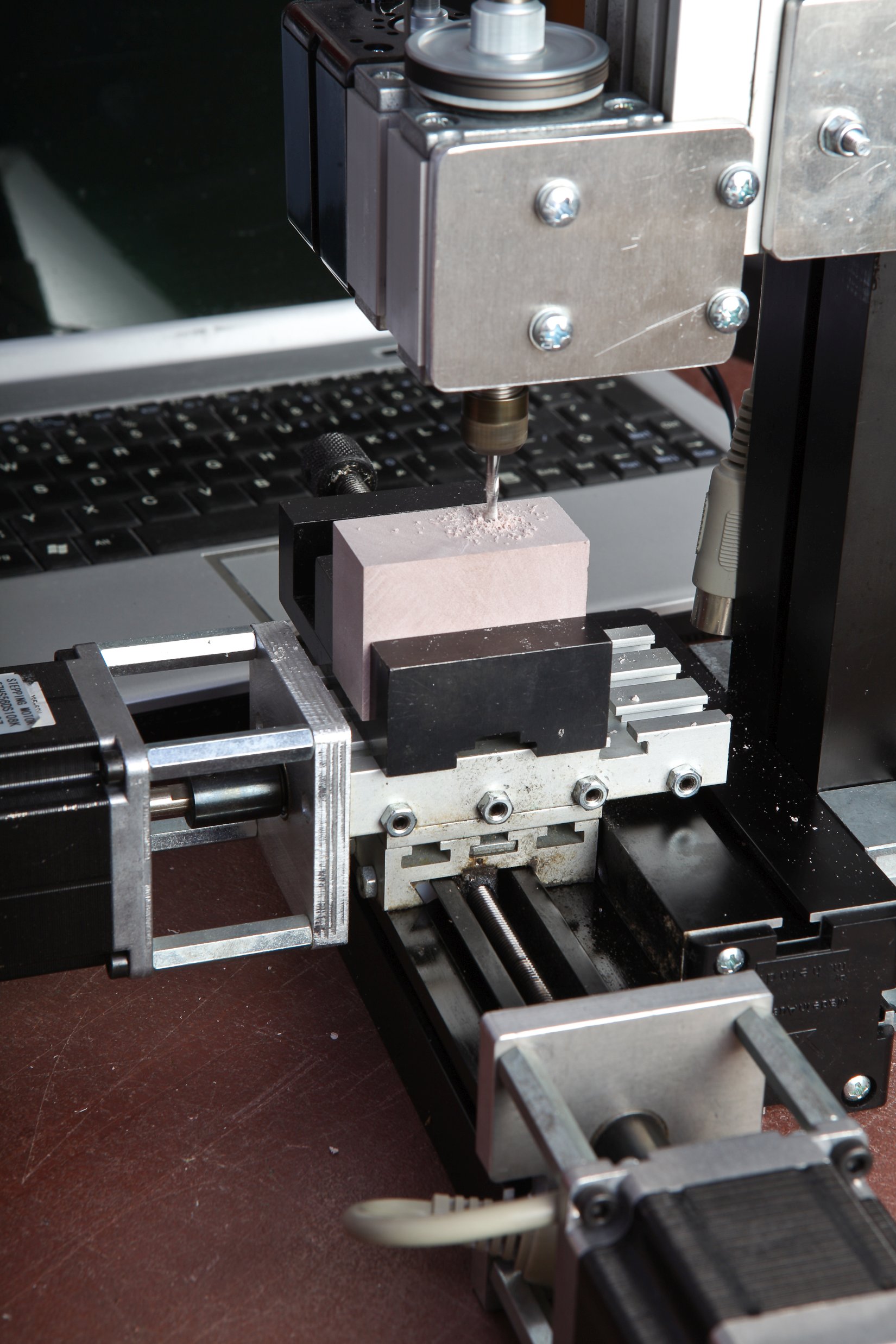

Vertical milling machine / drilling machine:

Two slides form the cross table, the third slide results in the Z axis. The handwheels allow accurate drilling of holes with a specific depth and position. Collets from 1 to 6mm shaft thickness.

Supplied with machine bed (140 and 271mm), longitudinal slide (200mm), 2 x cross slide (90mm), tailstock, metal spacers, metal 3-jaw chuck, countershaft, 12 V motor, 12 V safety transformer, mounting plates u.v.m.