-

Tools/supplies

-

Drilling, polishing, grinding

-

Turning

-

Facilities, compressed air and vacuum

-

Goldsmith special tools/GRS

-

Small tools

-

Soldering, melting, casting, welding

-

Measuring and testing

-

Surface treatment

-

Clean, dry, turning, sawing

-

CAD-software / software

-

Watchmaker tools

-

Sales and workshop tools

-

3D Werkzeuge & Reinigung

-

Drilling, polishing, grinding

-

Craft & creative

-

Advent calendar

-

Everything about molding

-

Everything about wood

-

Handicraft sets and tools

-

Poker work

-

Encaustic

-

Experiments

- Colors & polish

-

Galvanizing

-

(Glass) Engraving

-

Kerzen gießen

-

Adhesives

-

Crib construction

-

Jigsaw

-

Soldering & welding

-

Model kits

-

Collector models

-

Sharpening

-

Writing instruments

-

Soap casting

-

teifoc stone building sets

-

Gilding

-

Tools & machines

-

Pouring tin - material and equipment

-

Advent calendar

slide 2 of 4

slide 1 to 4 of 4

Dip and brush bluing stain 200ml

Product number:

363075

Packaging Unit:

1

Delivery time approx. 1 week

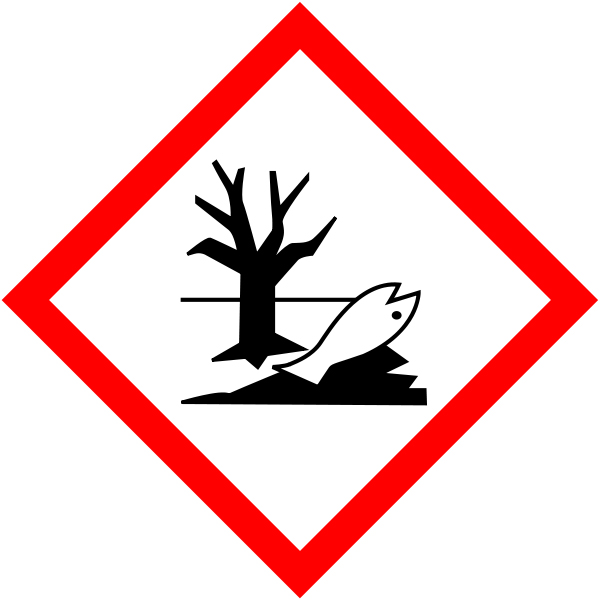

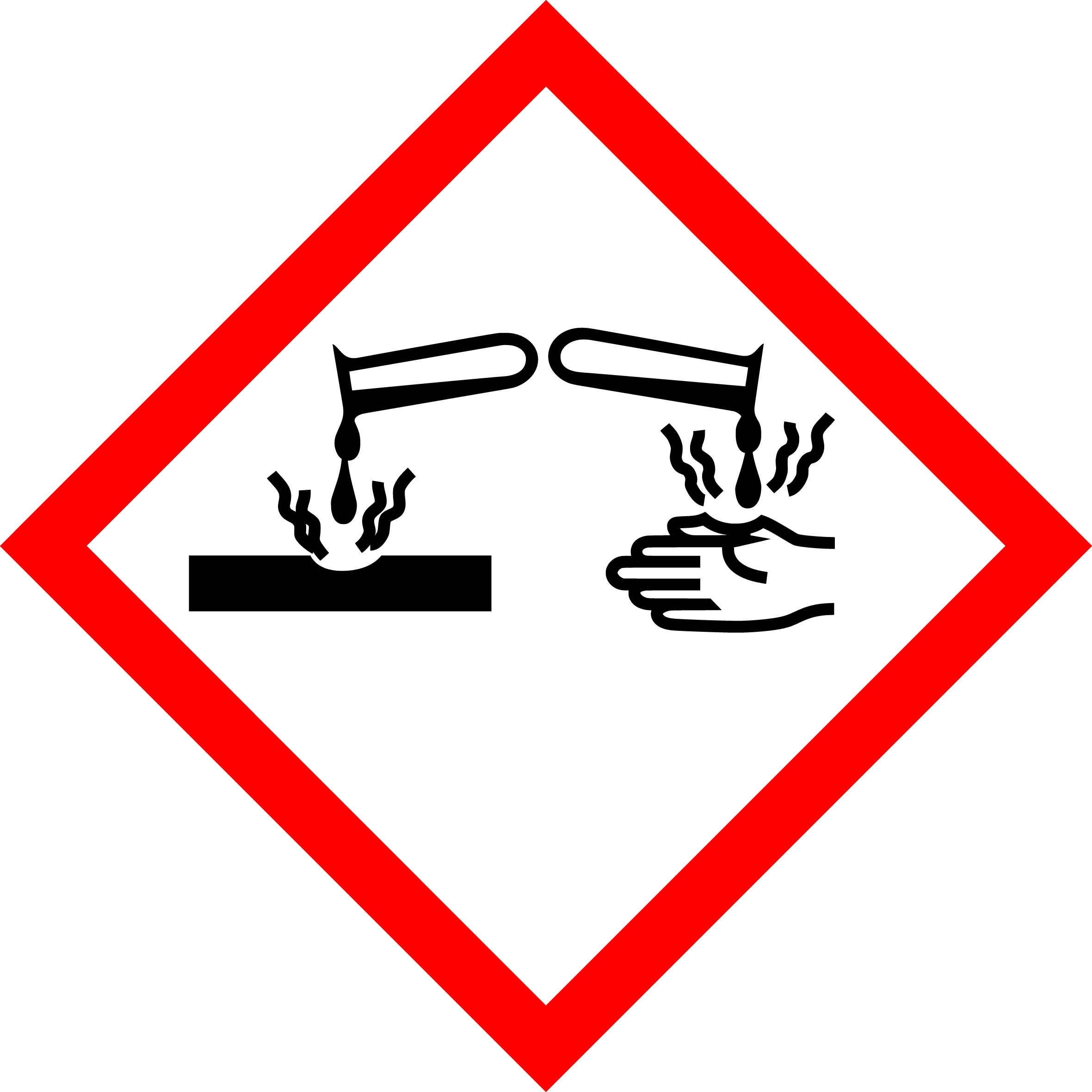

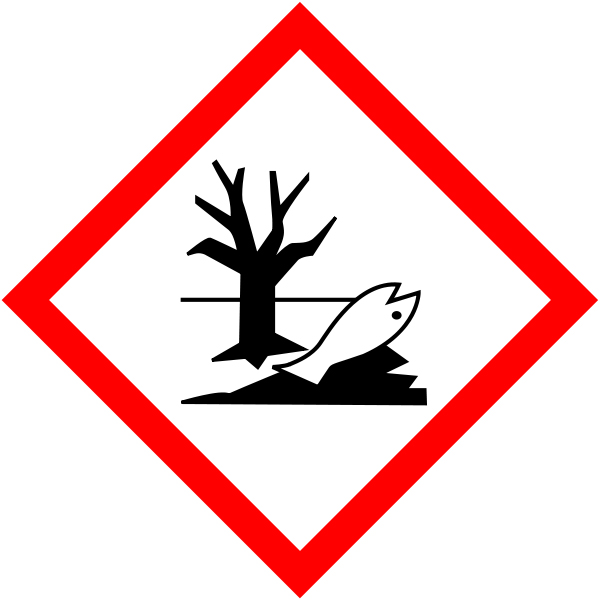

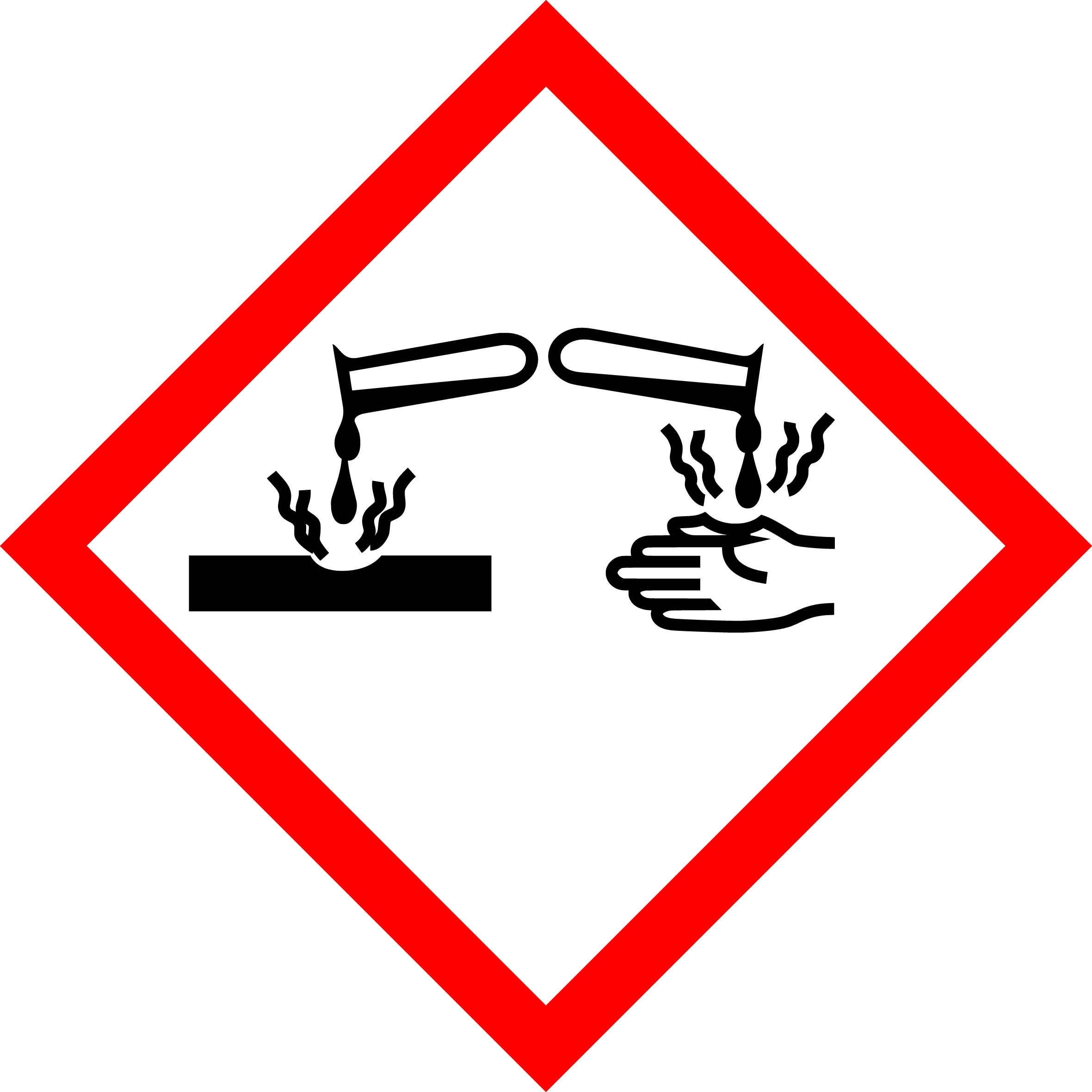

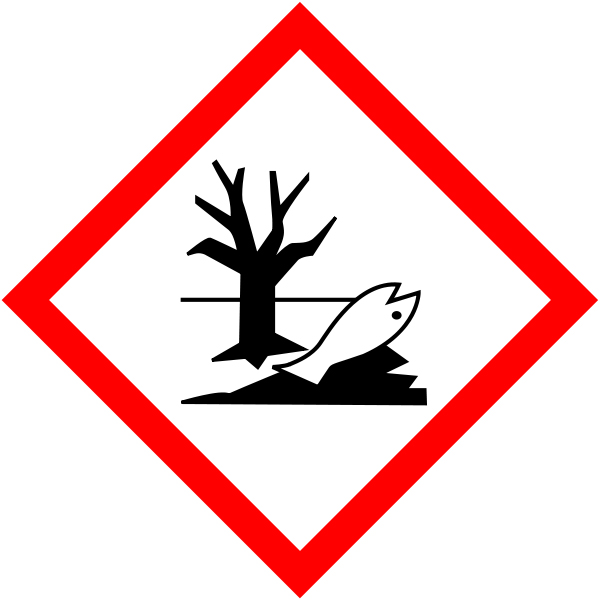

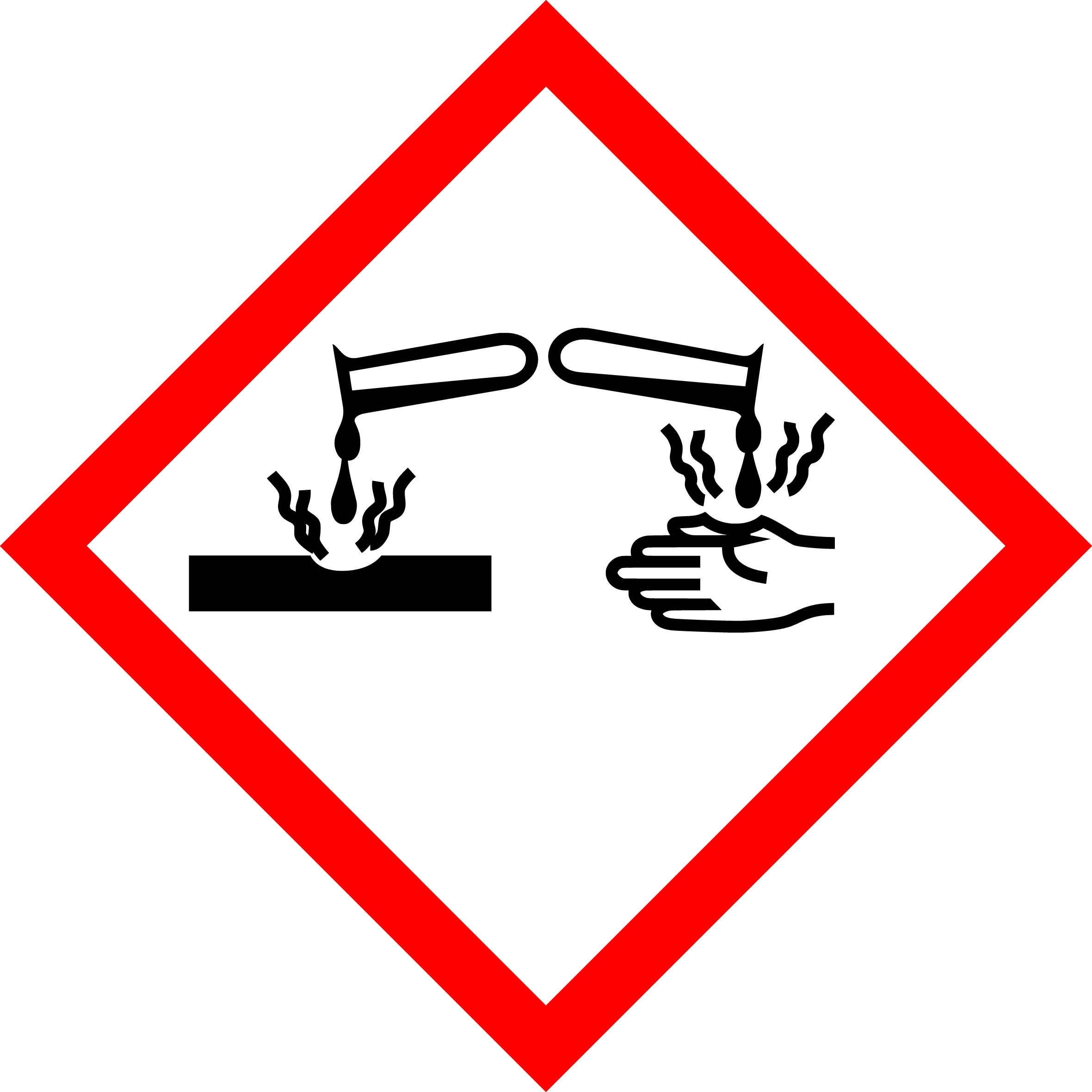

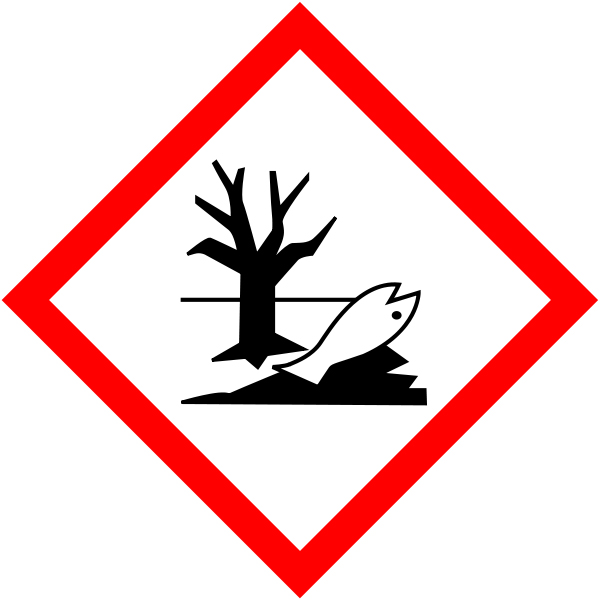

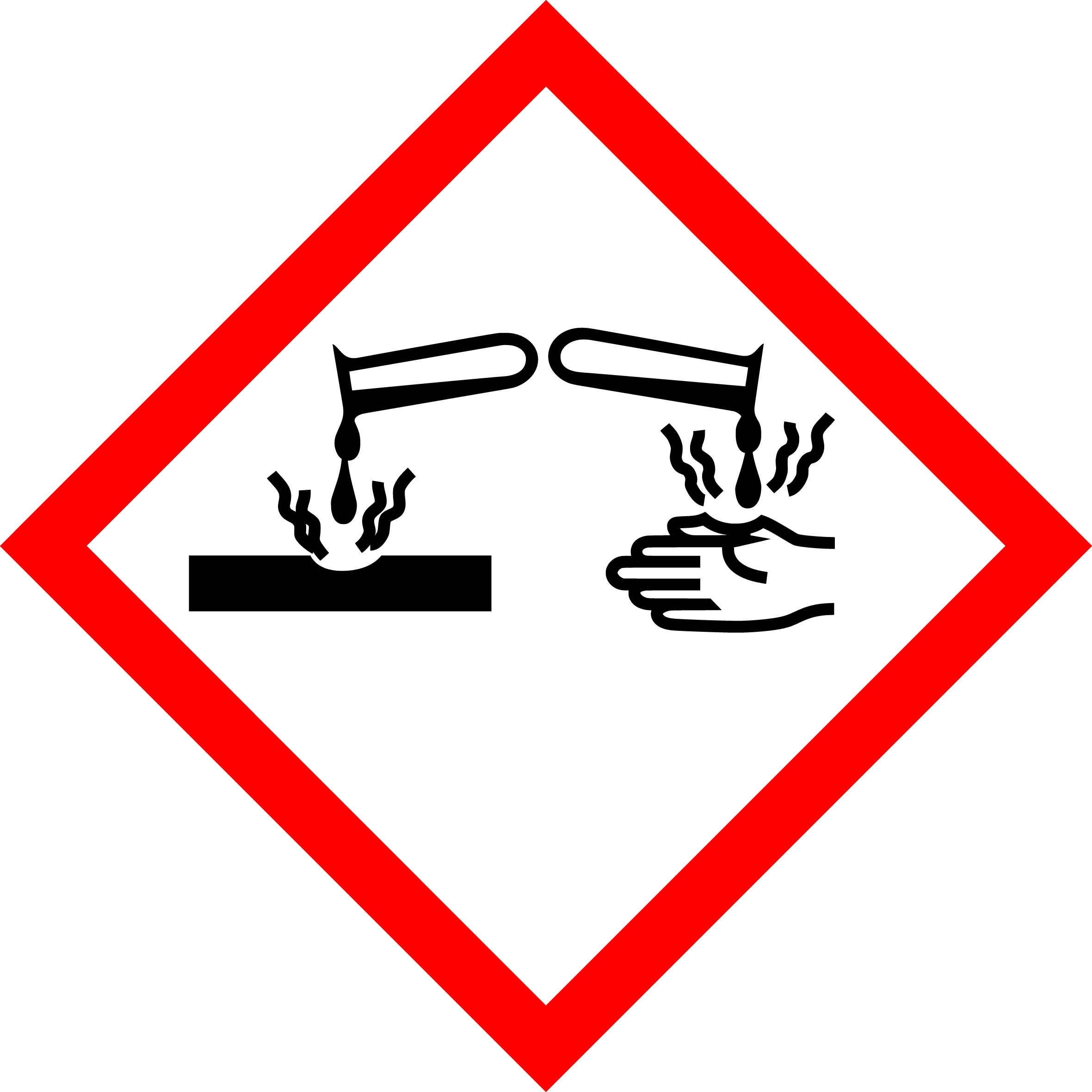

Dangerous goods information

| Description | Ätzender sauerer anorganischer füssiger Stoff n.a.g. ( Salpetersäüre ,Phosphorsäure ) |

|---|---|

| Dangerous goods from: | 130 |

| Dangerous goods class: | 8 |

| UN-Nummer: | 3264 |

| Dangerous goods information: |

| Application: | Altering brass, bronze, copper |

|---|---|

| Article name: | Bluing set |

| Brand: | Piccolino |

| Colour: | brown / black |

| Content: | 200,00 |

| Dangerous goods from quantity: | 130 |

| Unit content: | ml |

Manufacturer Informations

Name: Piccolina

Street: Montfortstr. 15

City: 88069 Tettnang

Country: DE

Email: picco.lina@web.de

Phone: 07542/9477922

0 of 0 reviews

Login

No reviews found. Be the first to share your insights.

Accessoires (optional)

slide 1 to 3 of 3

Processing mode:

sehr fein

Made..

- for matting high-gloss surfaces

- for polishing waxed woods with new wax

- to bring copper and brass to a shine

- to dry glass

RAKSO steel wool

8 pads, a total of 200 g.

The practical 8 PADS format is aimed at home improvement and craftsmen who work on smaller surfaces and expect a user-friendly pre-portioning of the steel wool.

RAKSO is the synonym for steel wool in Germany and in many European countries. Derived from the first name of the company founder Oscar Weil, the RAKSO brand was created as early as 1901. For more than 100 years, a unique, wide assortment of steel wool products has been established under this brand umbrella.

As with the company founder, the guiding principle "quality first" is still valid today, both for the traditional and for all new products. This is how RAKSO stands today

Steel wool characterized by purity, elasticity and environmental friendliness.

Premium quality since 1901

VARIANTS:

00 = reference 334834 (fine)

000 = reference 334833 (very fine)

0000 = reference 345949 (exrrem fine)

These fine grades 0000, 000 and 00 of the RAKSO STAHLWOLLE-PADS are particularly suitable for polishing, for the fine intermediate sanding and for cleaning more sensitive

Surfaces.

Including detailed work instructions and exact application recommendations.

Processing mode:

fein

Made..

- for matting high-gloss surfaces

- for polishing waxed woods with new wax

- to bring copper and brass to a shine

- to dry glass

RAKSO steel wool

8 pads, a total of 200 g.

The practical 8 PADS format is aimed at home improvement and craftsmen who work on smaller surfaces and expect a user-friendly pre-portioning of the steel wool.

RAKSO is the synonym for steel wool in Germany and in many European countries. Derived from the first name of the company founder Oscar Weil, the RAKSO brand was created as early as 1901. For more than 100 years, a unique, wide assortment of steel wool products has been established under this brand umbrella.

As with the company founder, the guiding principle "quality first" is still valid today, both for the traditional and for all new products. This is how RAKSO stands today

Steel wool characterized by purity, elasticity and environmental friendliness.

Premium quality since 1901

VARIANTS:

00 = reference 334834 (fine)

000 = reference 334833 (very fine)

0000 = reference 345949 (exrrem fine)

These fine grades 0000, 000 and 00 of the RAKSO STAHLWOLLE-PADS are particularly suitable for polishing, for the fine intermediate sanding and for cleaning more sensitive

Surfaces.

Including detailed work instructions and exact application recommendations.

Processing mode:

extreme fine

Made..

- for matting high-gloss surfaces

- for polishing waxed woods with new wax

- to bring copper and brass to a shine

- to dry glass

RAKSO steel wool

8 pads, a total of 200 g.

The practical 8 PADS format is aimed at home improvement and craftsmen who work on smaller surfaces and expect a user-friendly pre-portioning of the steel wool.

RAKSO is the synonym for steel wool in Germany and in many European countries. Derived from the first name of the company founder Oscar Weil, the RAKSO brand was created as early as 1901. For more than 100 years, a unique, wide assortment of steel wool products has been established under this brand umbrella.

As with the company founder, the guiding principle "quality first" is still valid today, both for the traditional and for all new products. This is how RAKSO stands today

Steel wool characterized by purity, elasticity and environmental friendliness.

Premium quality since 1901

VARIANTS:

00 = reference 334834 (fine)

000 = reference 334833 (very fine)

0000 = reference 345949 (exrrem fine)

These fine grades 0000, 000 and 00 of the RAKSO STAHLWOLLE-PADS are particularly suitable for polishing, for the fine intermediate sanding and for cleaning more sensitive

Surfaces.

Including detailed work instructions and exact application recommendations.

Product information "Dip and brush bluing stain 200ml"

The term "browning" comes from the word "tanning".

This also includes the blackening, which is mainly used for ferrous articles at a temperature of 300° C or higher. And because this method is far too complex and dangerous for normal domestic use, a so-called brush burnishing, which can be ideally processed at a temperature of 12 to 25° C, is used here.

Many items made of brass, copper or bronze become unsightly over time and need to be reworked. This includes, for example, lamps, candlesticks, lamp bases, vases, handles, candlesticks, figures, fittings and much more.

The partly spotted or soiled surface is first cleaned of dirt and dust adhesions with a common household cleaning agent. This is followed by rubbing with a cloth moistened with solvent to remove paint residue, oil and grease. The object is then carefully sanded down on all sides with fine steel wool (e.g. our reference 334833, 345949 or 334834) in such a way that the original metal color is visible again over the entire surface.

Only then does the burnishing follow.

To do this, the object is thinly painted over with a soft brush soaked in immersion and brush bluing stain. The stain adhering to the metal surface is moved with a brush until it changes colour. This starts with light brown, goes to a medium reddish brown, dark brown to deep black. If the desired color appears, the object is immediately held under running tap water to stop the browning. If this moment has been missed so that the part has become too dark, this can easily be corrected again: To do this, it is rubbed down again with steel wool and then blued again.

After drying, the surface is rubbed with an oily cloth. This prevents further oxidation (browning), which can happen due to humidity. When processing this metal stain, protective gloves and goggles must be worn, which you can also find in our shop.

Black stain contains harmful substances and is labeled according to the CLP regulation.

Brush cleaning with water.

MADE IN GERMANY

CLP classification: Danger

This also includes the blackening, which is mainly used for ferrous articles at a temperature of 300° C or higher. And because this method is far too complex and dangerous for normal domestic use, a so-called brush burnishing, which can be ideally processed at a temperature of 12 to 25° C, is used here.

Many items made of brass, copper or bronze become unsightly over time and need to be reworked. This includes, for example, lamps, candlesticks, lamp bases, vases, handles, candlesticks, figures, fittings and much more.

The partly spotted or soiled surface is first cleaned of dirt and dust adhesions with a common household cleaning agent. This is followed by rubbing with a cloth moistened with solvent to remove paint residue, oil and grease. The object is then carefully sanded down on all sides with fine steel wool (e.g. our reference 334833, 345949 or 334834) in such a way that the original metal color is visible again over the entire surface.

Only then does the burnishing follow.

To do this, the object is thinly painted over with a soft brush soaked in immersion and brush bluing stain. The stain adhering to the metal surface is moved with a brush until it changes colour. This starts with light brown, goes to a medium reddish brown, dark brown to deep black. If the desired color appears, the object is immediately held under running tap water to stop the browning. If this moment has been missed so that the part has become too dark, this can easily be corrected again: To do this, it is rubbed down again with steel wool and then blued again.

After drying, the surface is rubbed with an oily cloth. This prevents further oxidation (browning), which can happen due to humidity. When processing this metal stain, protective gloves and goggles must be worn, which you can also find in our shop.

Black stain contains harmful substances and is labeled according to the CLP regulation.

Brush cleaning with water.

MADE IN GERMANY

CLP classification: Danger