-

Tools/supplies

-

Drilling, polishing, grinding

-

Turning

-

Facilities, compressed air and vacuum

-

Goldsmith special tools/GRS

-

Small tools

-

Soldering, melting, casting, welding

-

Measuring and testing

-

Surface treatment

-

Files

-

Electroplate

- Electroplating equipment

-

Accessories for all galvanic devices

-

Accessories for equipment container

-

Accessories for RM01

-

Anodes

-

Stiftgalvanik

-

Stiftgalvanik chemicals

-

Stiftgalvanik accessories

-

Galvanic degreasing

-

Chemicals for the preparation

-

Chemicals for electroplating power

-

Chemicals to the plating without current

-

Chemicals to shine (material ablation)

-

Blacking for silver

-

Surface protection

-

Engraving

-

Plating

-

Coatings

-

Sand blasting

-

Files

-

Clean, dry, turning, sawing

-

CAD-software / software

-

Watchmaker tools

-

Sales and workshop tools

-

Drilling, polishing, grinding

Rhodium Machine RMgo! Set 2 - for rhodium and cold gold color plating

Product number:

346336

Packaging Unit:

1

Extra order! Delivery time approx. 4 weeks, return is not possible.

| Application: | degrease, rhodium, gild |

|---|---|

| Article name: | RM Go |

| Brand: | Jentner |

| Gross weight grams: | 6.450 |

| Special feature: | Complete set |

Manufacturer Informations

Name: Jentner

Street: Johann-Staib-Str. 2

City: 75179 Pforzheim

Country: DE

Email: info@jentner.de

Phone: 07231-418094-0

0 of 0 reviews

Login

No reviews found. Be the first to share your insights.

Accessoires (required)

Colour:

Pale yellow 14 ct.

Use at room temperature, heating as for conventional electrolytes is not required. Low repair and maintenance costs since neither immersion heater nor thermostat or circulation is required.

Energy-efficient

Ready to use. Includes 1 g fine gold, contains cyanide.

To create decorative, thin but hard colour gilding on all non-ferrous and precious metal alloys

Contents 1 litres

Application

Anodes - stainless steel

Tray: glass or plastic

Goods movement: no

Temperature: 18-25 °C

Voltage: 3V

Time: 10-30 seconds

Colour:

Red

Use at room temperature, heating as for conventional electrolytes is not required. Low repair and maintenance costs since neither immersion heater nor thermostat or circulation is required.

Energy-efficient

Ready to use. Includes 1 g fine gold, contains cyanide.

To create decorative, thin but hard colour gilding on all non-ferrous and precious metal alloys

Contents 1 litres

Application

Anodes - stainless steel

Tray: glass or plastic

Goods movement: no

Temperature: 18-25 °C

Voltage: 3V

Time: 10-30 seconds

Colour:

rosegold

Use at room temperature, heating as for conventional electrolytes is not required. Low repair and maintenance costs since neither immersion heater nor thermostat or circulation is required.

Energy-efficient

Ready to use. Includes 1 g fine gold, contains cyanide.

To create decorative, thin but hard colour gilding on all non-ferrous and precious metal alloys

Contents 1 litres

Application

Anodes - stainless steel

Tray: glass or plastic

Goods movement: no

Temperature: 18-25 °C

Voltage: 3V

Time: 10-30 seconds

Preparation salt, cyanide, 60-90 g per litre. For all articles for degreasing before electroplating treatment.

Application:

Anodes - stainless steel

Tray - glass/PPH

Goods movement - no

Temperature - 15-30 °C

Voltage - 8-10 V

Time - 30-60 sec.

Concentrate with 2 g of rhodium per litre.

The products achieve dark, anthracite rhodium plating and are extremely resistant to abrasion.

Application:

Anodes - titanium/mixed oxide

Tray - Glass/PPH

Goods movement - yes

Temperature - 18-25 °C

Voltage - 1.8-2.2 V

Time - 1-2 minutes

Article name:

Ruthenium bath JE 12

Ready to use. Includes 5 g ruthenium.

The products obtain a dark, grey-black surface. The bath preserves lasting shine.

Application:

Anodes - titanium or mixed oxide

Tray - PPH

Goods movement - yes

Temperature - 60-70 °C

Voltage - 2-3 V

Time - 2-4 minutes

Colour:

Fine gold colour

Use at room temperature, heating as for conventional electrolytes is not required. Low repair and maintenance costs since neither immersion heater nor thermostat or circulation is required.

Energy-efficient

Ready to use. Includes 1 g fine gold, contains cyanide.

To create decorative, thin but hard colour gilding on all non-ferrous and precious metal alloys

Contents 1 litres

Application

Anodes - stainless steel

Tray: glass or plastic

Goods movement: no

Temperature: 18-25 °C

Voltage: 3V

Time: 10-30 seconds

For rhodium plating. Fits galvanising unit RM01

Für Rhodiniergerät RM01.

Rotes Kabel mit Stecker nicht im Lieferumfang enthalten.

Product information "Rhodium Machine RMgo! Set 2 - for rhodium and cold gold color plating"

Pre-set processing times and voltages, together with an automatic energy cut-off, allow a professional end result.

The time intervals can be selected between 15, 30 or 60 seconds.

This guarantees a reliable calculation. Set processing time - GO! Key and, in conjunction with Jentner's unique electrolytes, which are already deposited perfectly at room temperature, Rinse and ready! The RMGO is so simple and user-friendly!

Your advantages:

Rhodium savings due to pre-settable deposition time. Optimal is a coating interval of 30-60 seconds to obtain a high-quality surface.

Model calculation:

A deposit time of 36 seconds instead of 30 seconds will cost you 20% more of your expensive rhodium. This is a cost savings of 0.2 g of rhodium at 1000 rings when coated exactly 30 seconds.

Absolutely safe process, since the voltage does not have to be adjusted - easy handling by only one GO! button

Errors are avoided, as trained employees quickly get to grips with each other

More than 1000 rings with 1 L rhodium solution JE88 and a brilliant and glossy surface

The baths are available as concentrates or ready for use

This Set includes:

3 x Beaker 1000ml incl. Cover

3 x Beaker 600ml incl. Cover

3 x red Cable

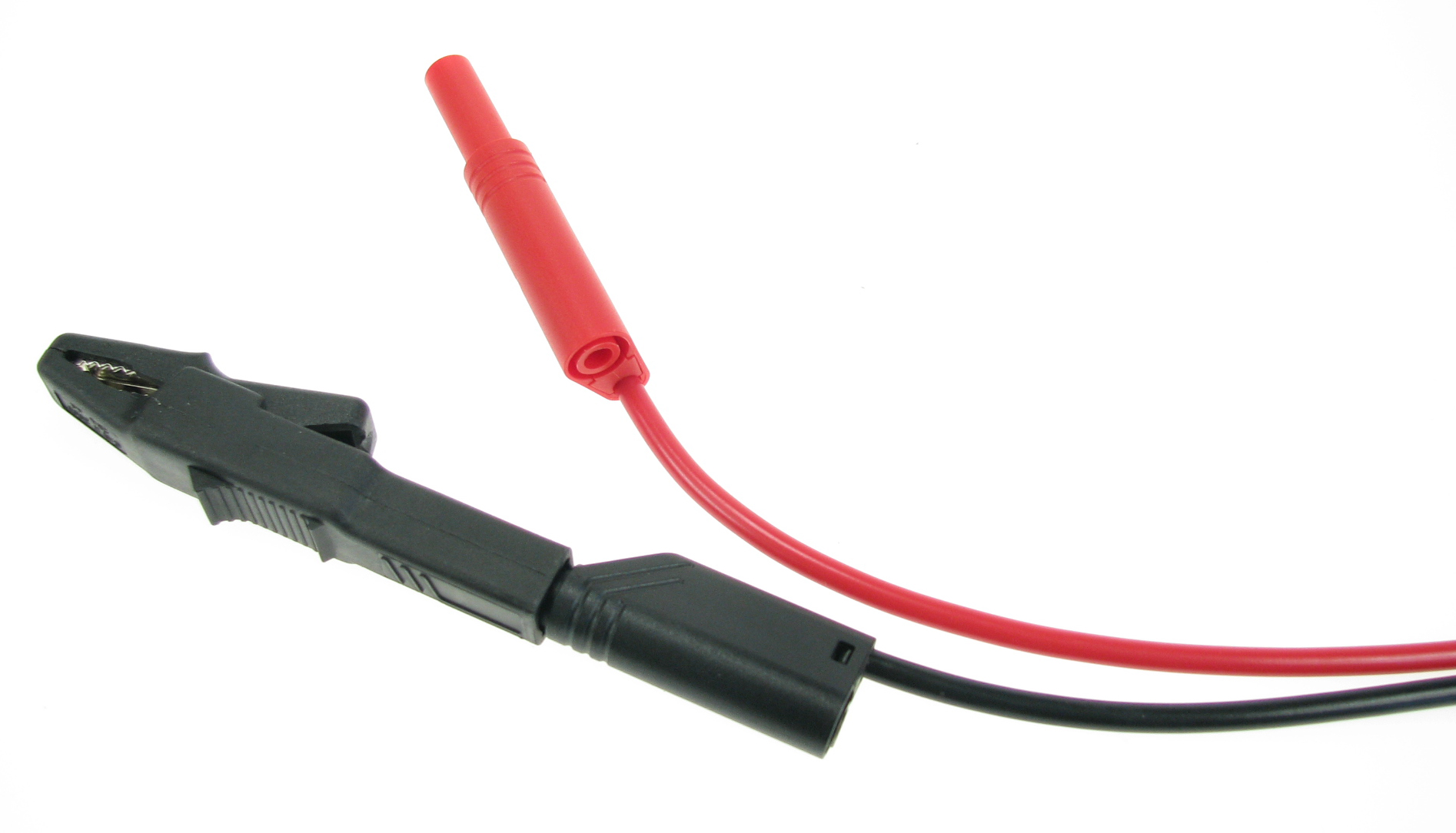

1 x black Cable with crocodile clip

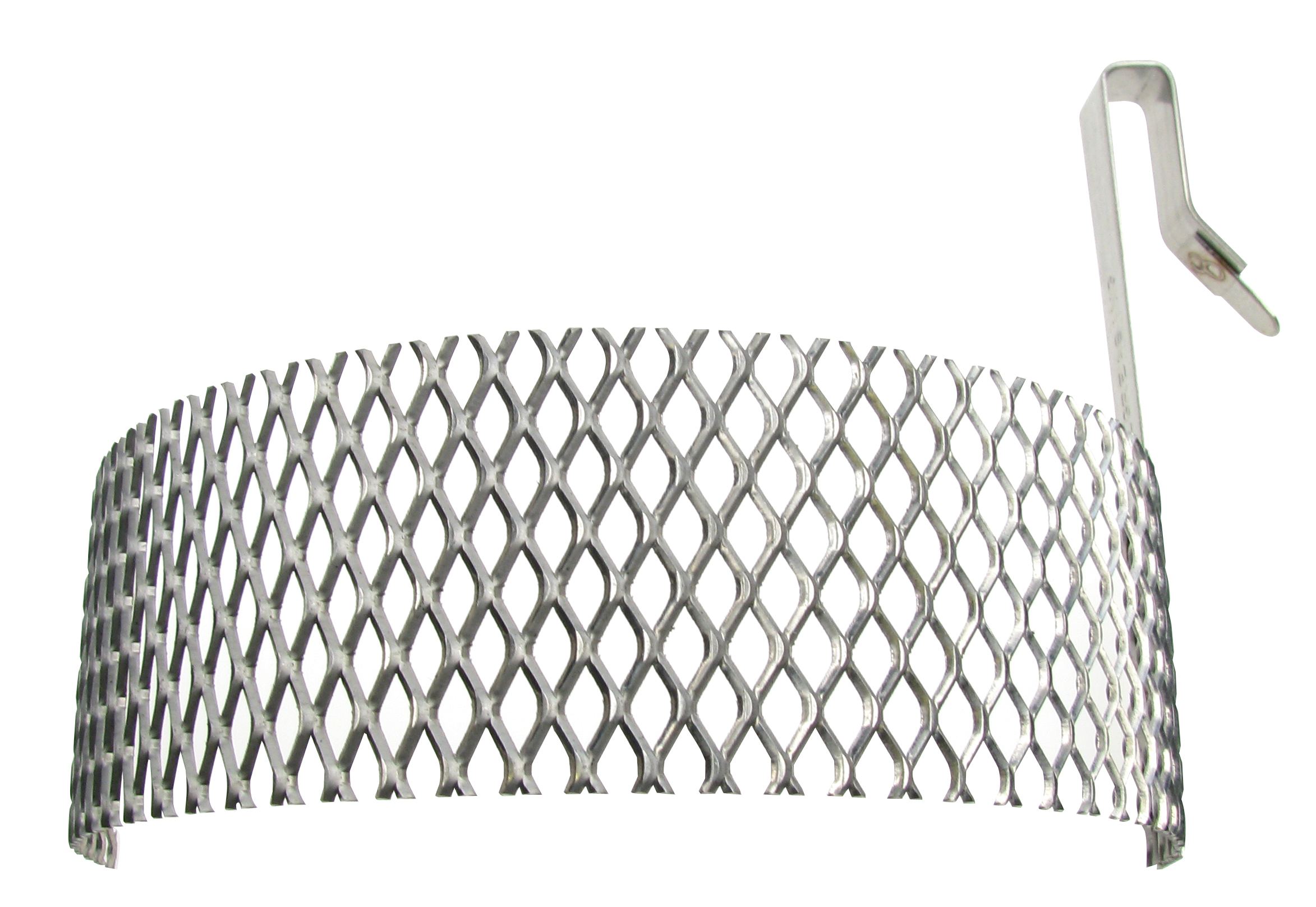

2 x Stainless steel anode

1 x Mixed oxide anode

1 x Jig with 4 hooks

The time intervals can be selected between 15, 30 or 60 seconds.

This guarantees a reliable calculation. Set processing time - GO! Key and, in conjunction with Jentner's unique electrolytes, which are already deposited perfectly at room temperature, Rinse and ready! The RMGO is so simple and user-friendly!

Your advantages:

Rhodium savings due to pre-settable deposition time. Optimal is a coating interval of 30-60 seconds to obtain a high-quality surface.

Model calculation:

A deposit time of 36 seconds instead of 30 seconds will cost you 20% more of your expensive rhodium. This is a cost savings of 0.2 g of rhodium at 1000 rings when coated exactly 30 seconds.

Absolutely safe process, since the voltage does not have to be adjusted - easy handling by only one GO! button

Errors are avoided, as trained employees quickly get to grips with each other

More than 1000 rings with 1 L rhodium solution JE88 and a brilliant and glossy surface

The baths are available as concentrates or ready for use

This Set includes:

3 x Beaker 1000ml incl. Cover

3 x Beaker 600ml incl. Cover

3 x red Cable

1 x black Cable with crocodile clip

2 x Stainless steel anode

1 x Mixed oxide anode

1 x Jig with 4 hooks