-

Tools/supplies

-

Drilling, polishing, grinding

-

Turning

-

Facilities, compressed air and vacuum

-

Goldsmith special tools/GRS

-

Small tools

- Soldering, melting, casting, welding

-

Measuring and testing

-

Surface treatment

-

Clean, dry, turning, sawing

-

CAD-software / software

-

Watchmaker tools

-

Sales and workshop tools

-

3D Werkzeuge & Reinigung

-

Drilling, polishing, grinding

slide 2 of 13

slide 1 to 5 of 13

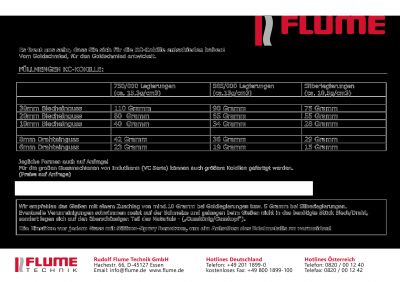

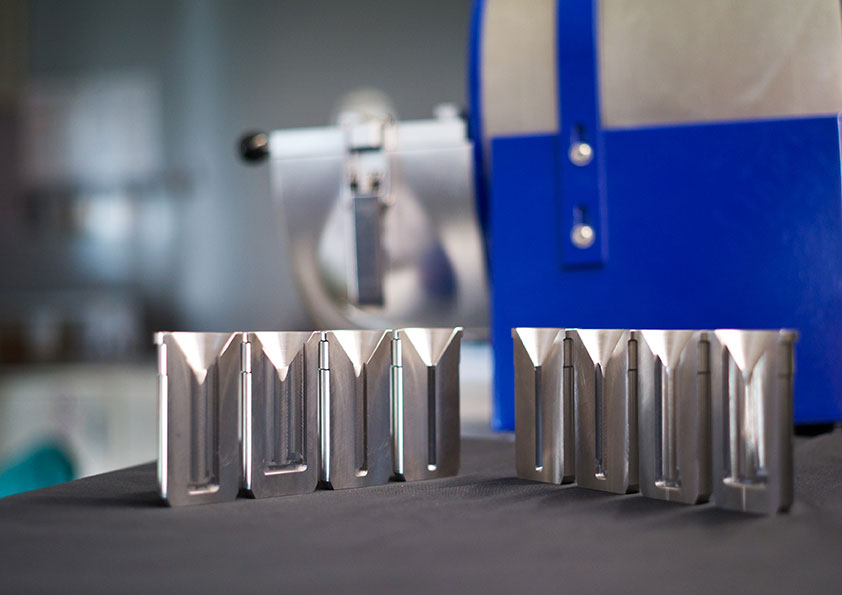

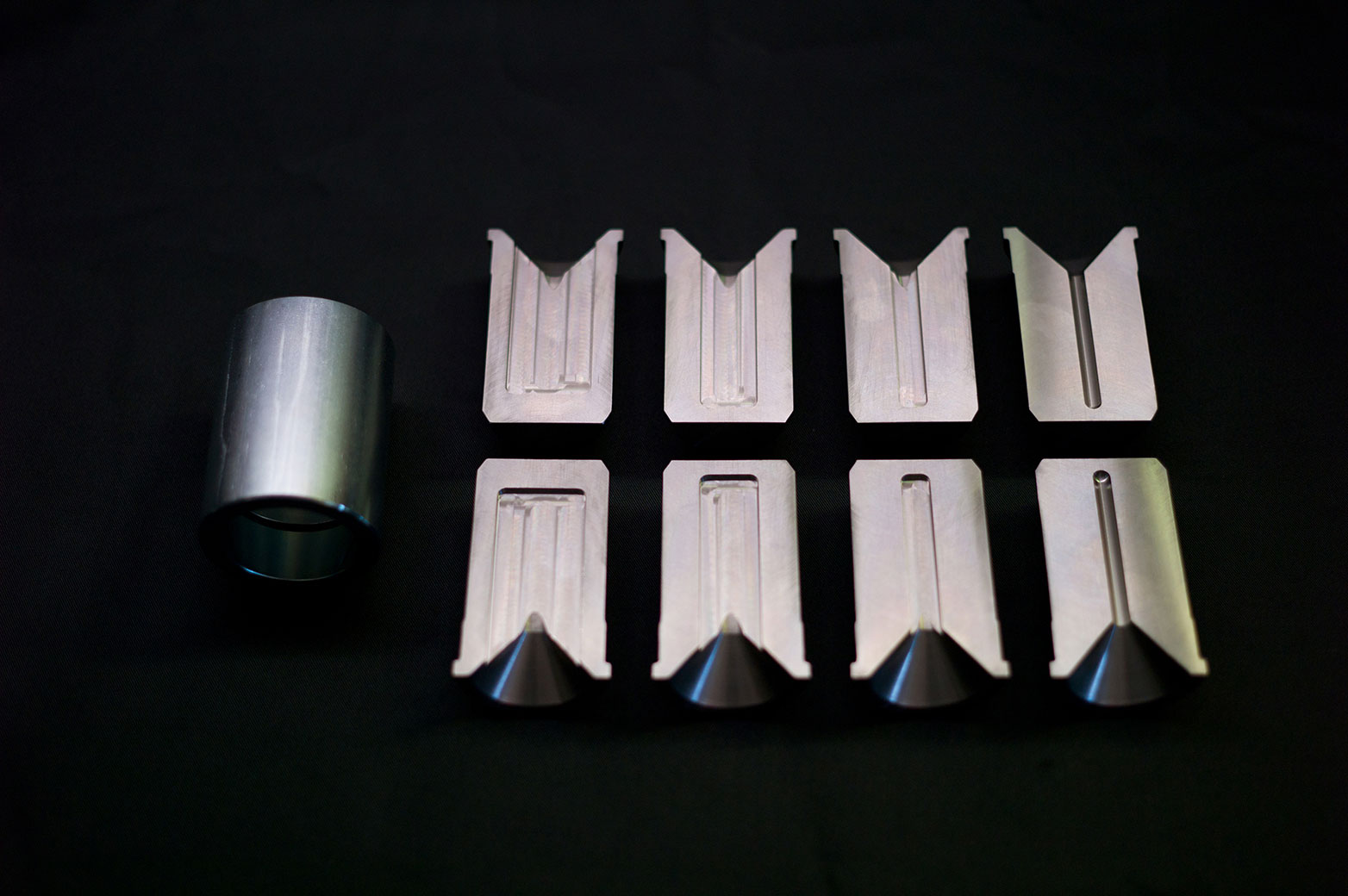

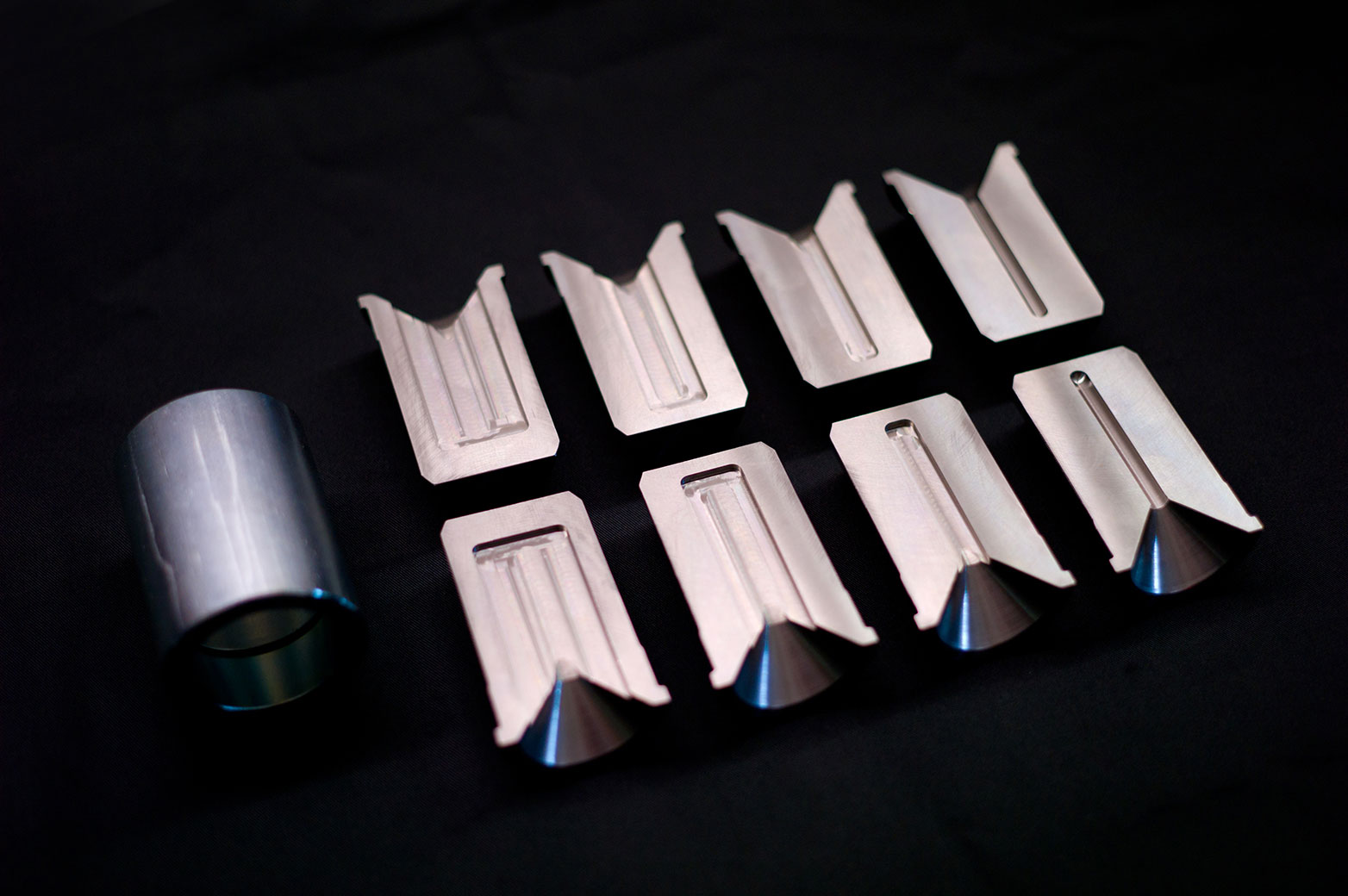

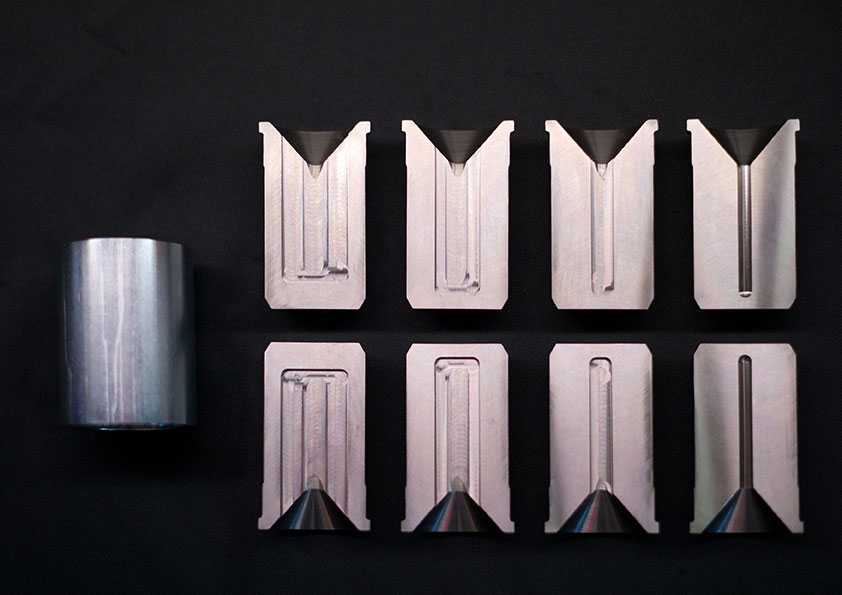

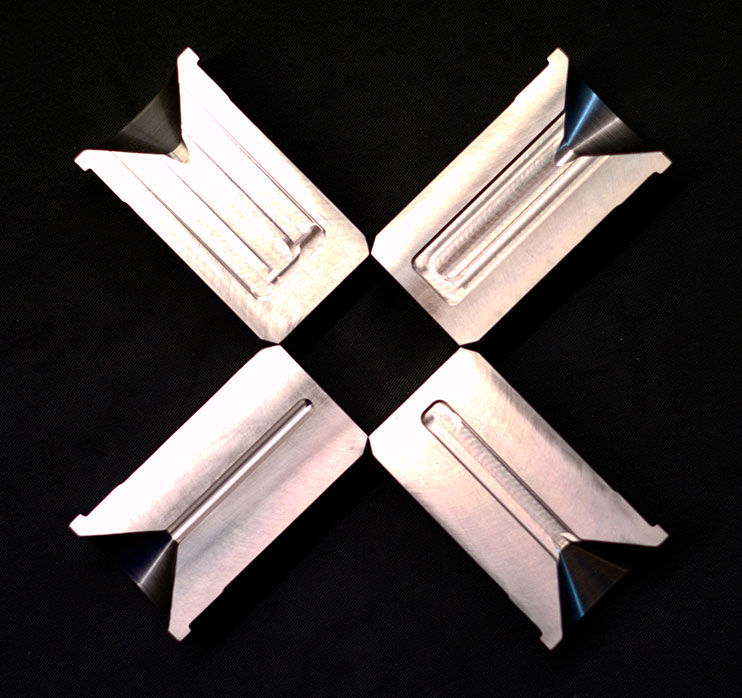

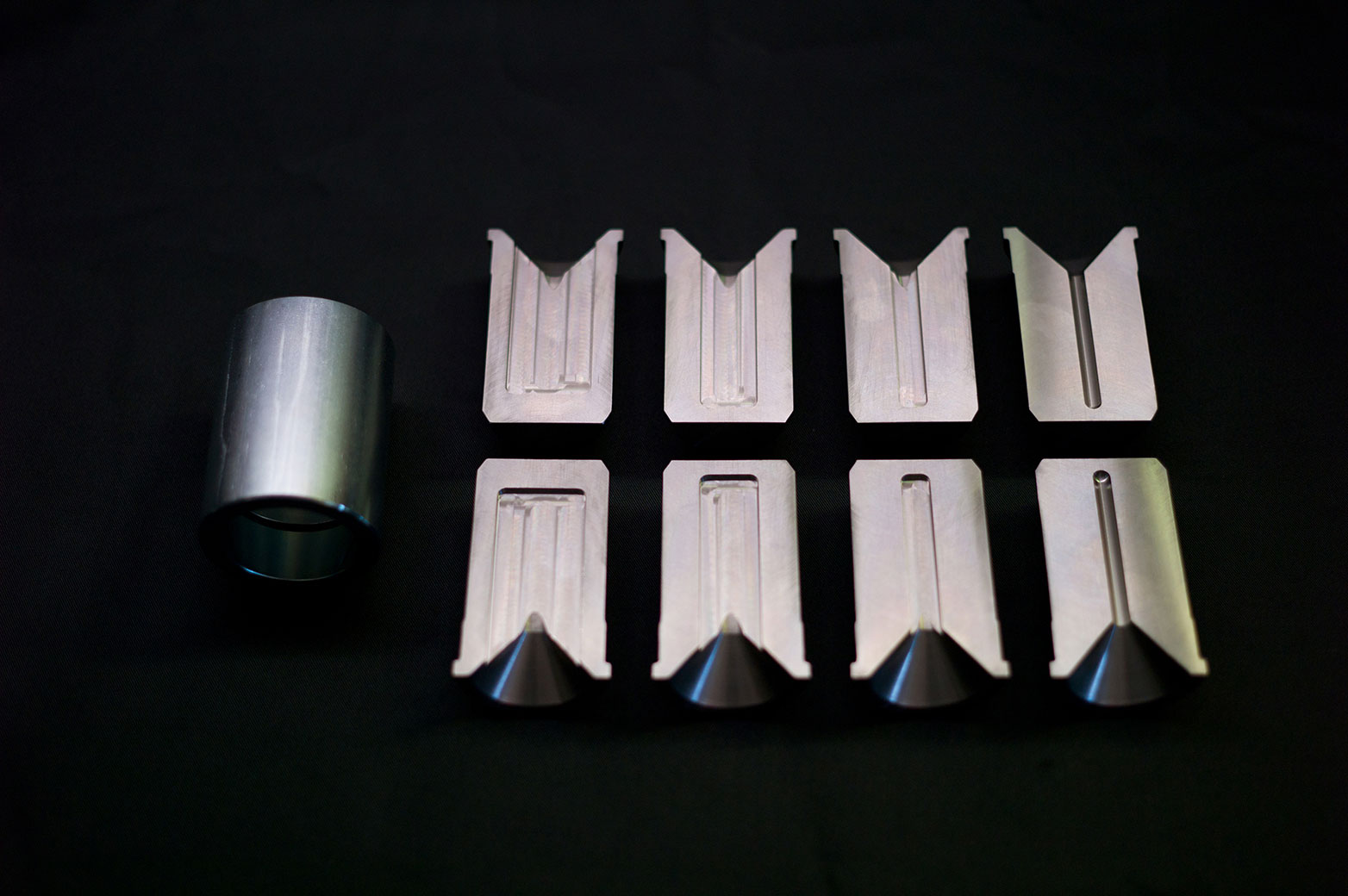

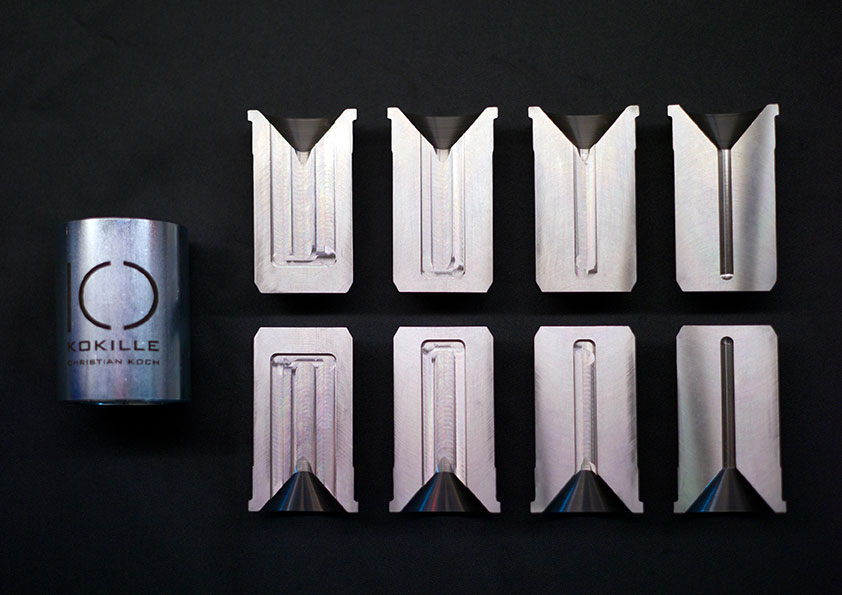

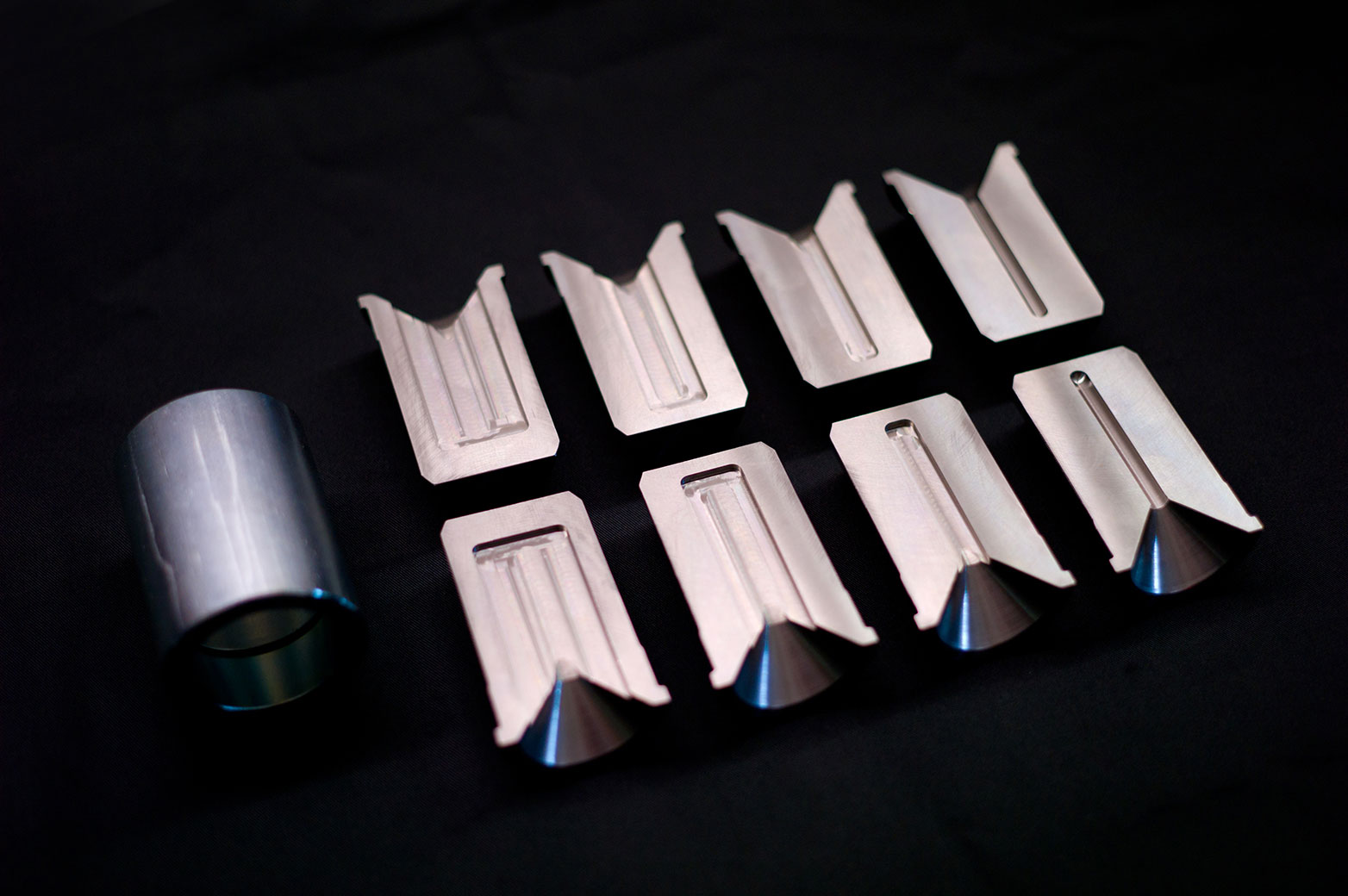

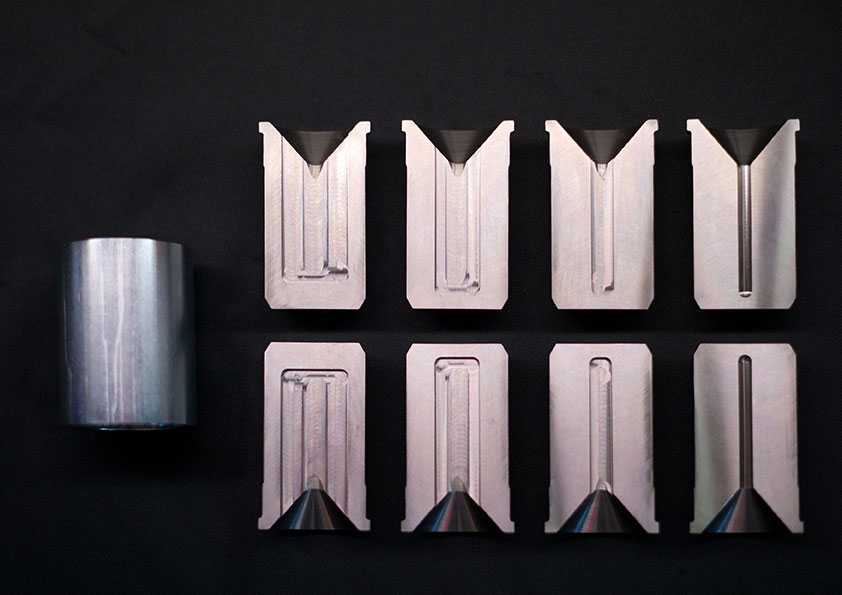

Sheet metal casting 20 x 55 x 5mm

Product number:

359033

Packaging Unit:

1

From Stock

Downloads

| Application: | Manufacture of semi-finished products |

|---|---|

| Article name: | Sheet metal casting |

| Brand: | Koch |

| Property: | 20 x 55 x 5mm |

| Special feature: | approx. 85gr |

0 of 0 reviews

Login

No reviews found. Be the first to share your insights.

Accessoires (required)

slide 1 of 1

Sleeve for our KC sprues with the references 359030, 359031, 359032, 359033 and 359034

Accessoires (optional)

slide 1 to 2 of 2

For the lubrication of highly stressed sliding surfaces of all kinds. Especially at low speeds and oscillating movements. Separation of temperature-stressed components. Corrosion protection on screws, pins, bolts, flanges, spindles and fits.

Semi-synthetic, white high-temperature paste. Prevents cold welding, rusting and sticking. Metal free. Very good wear and corrosion protection. Universally applicable. Resistant to hot and cold water as well as acids and alkalis.

Operating temperature range: –40 ° C to +1,400 ° C.

Contents: 400 ml

Application: Before treatment with ceramic paste, the parts must be clean and free of residues, dirt and moisture. Apply to the cleaned surfaces with a paintbrush, brush or lint-free cloth. Spray on the appropriate amount depending on the area of application.

Optimal release agent for gas shielded welding

In addition, silicone spray is suitable as a

• excellent lubricant and

• optimal care and protection agent for plastics and rubber.

• Also for eliminating noise on plastic cladding.

Mineral oil and grease-free release agent, lubricant and protective agent based on silicone. For plastics, rubber, metal and wood. Clean application. Spray the parts to be treated thinly and let them dry. Eliminates annoying noises in the plastic area. Impregnated and insulated. Pleasant smell.

Contents: 300 ml

Application: Spray the components to be treated thinly and evenly, repeat treatment if necessary. Do not use in the vicinity of painting stations. It must be ensured that silicone spray is not sprayed onto food or machine parts that come into direct contact with food.

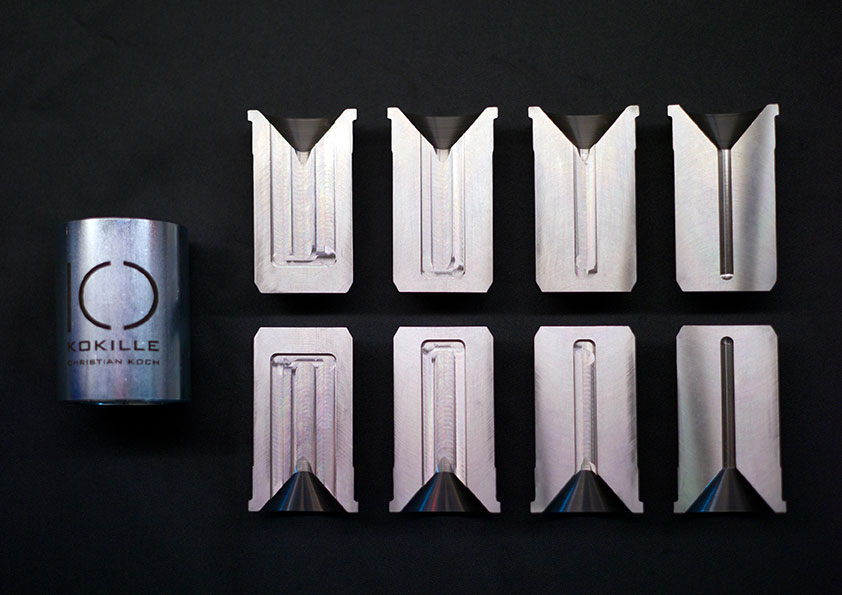

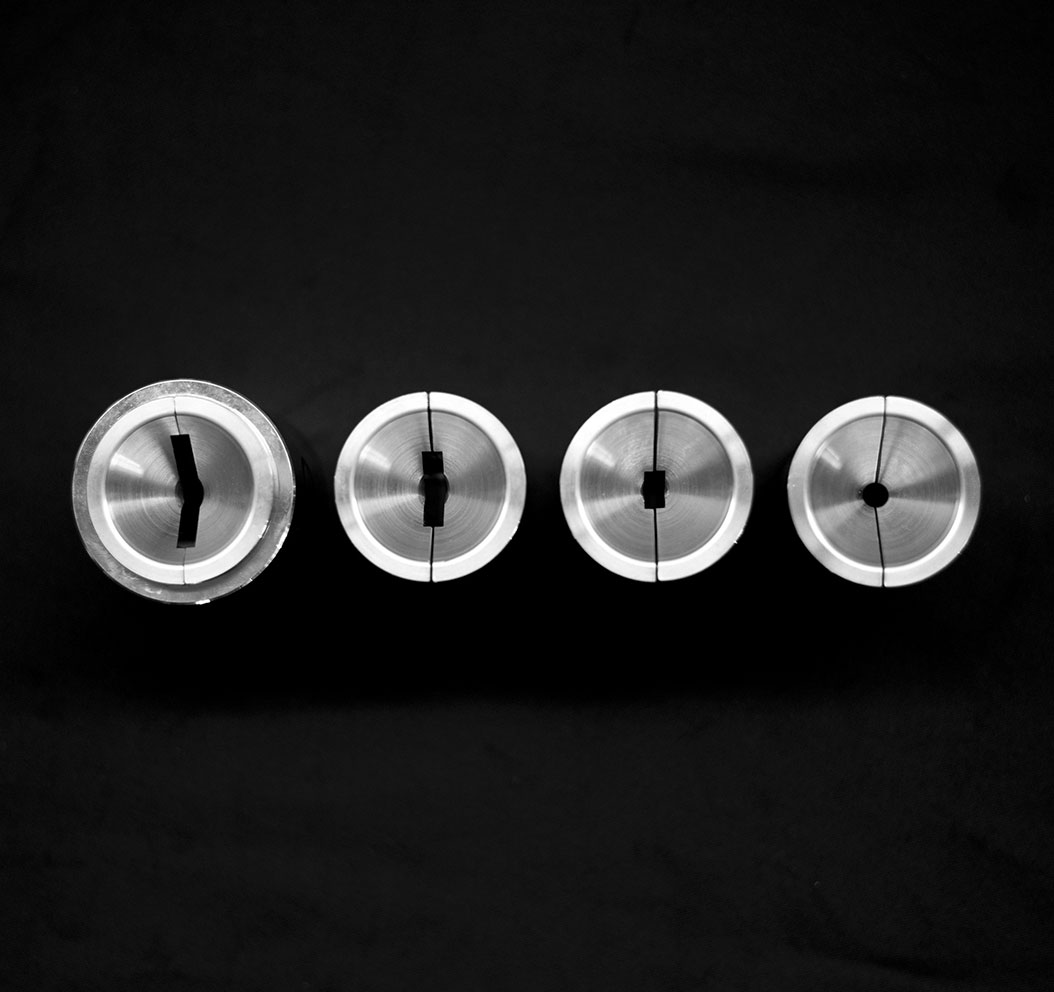

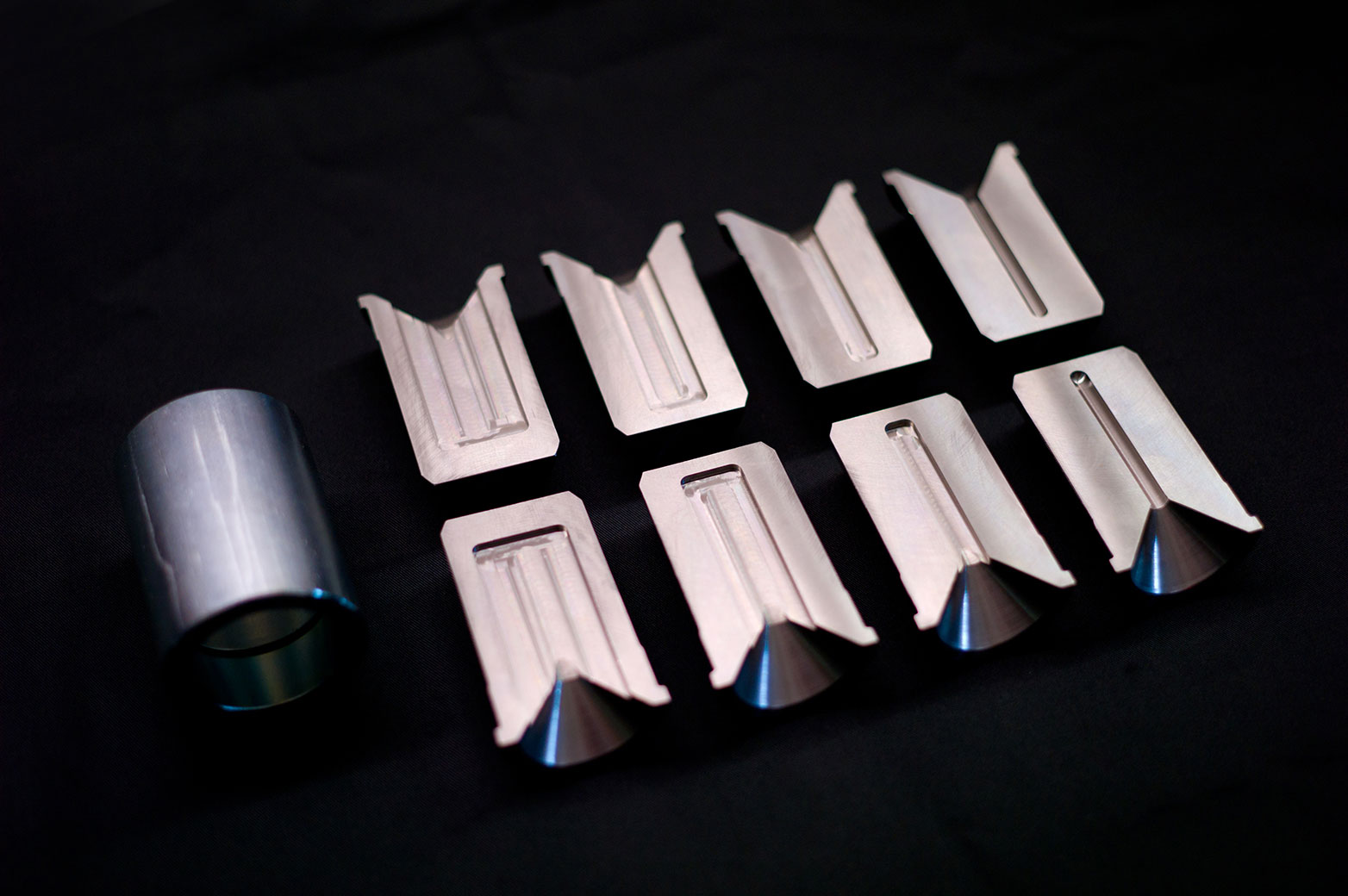

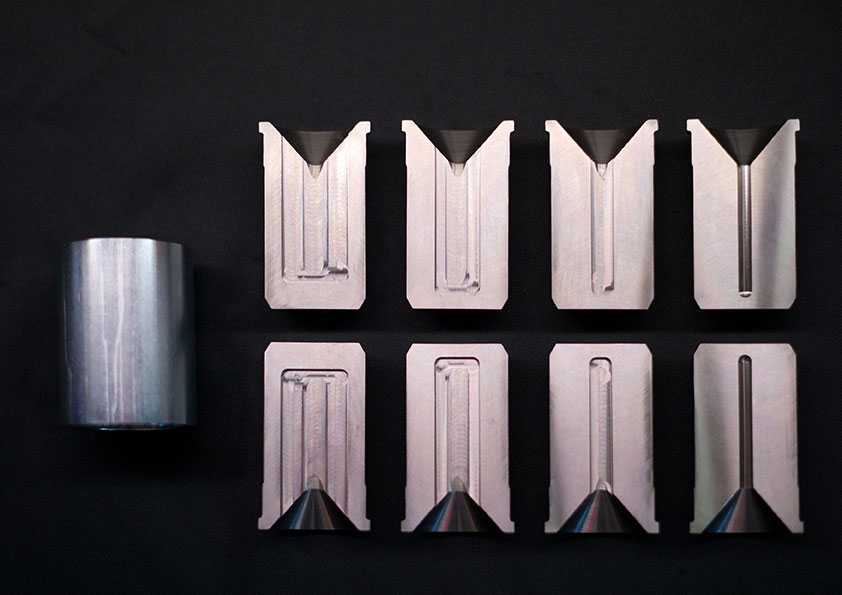

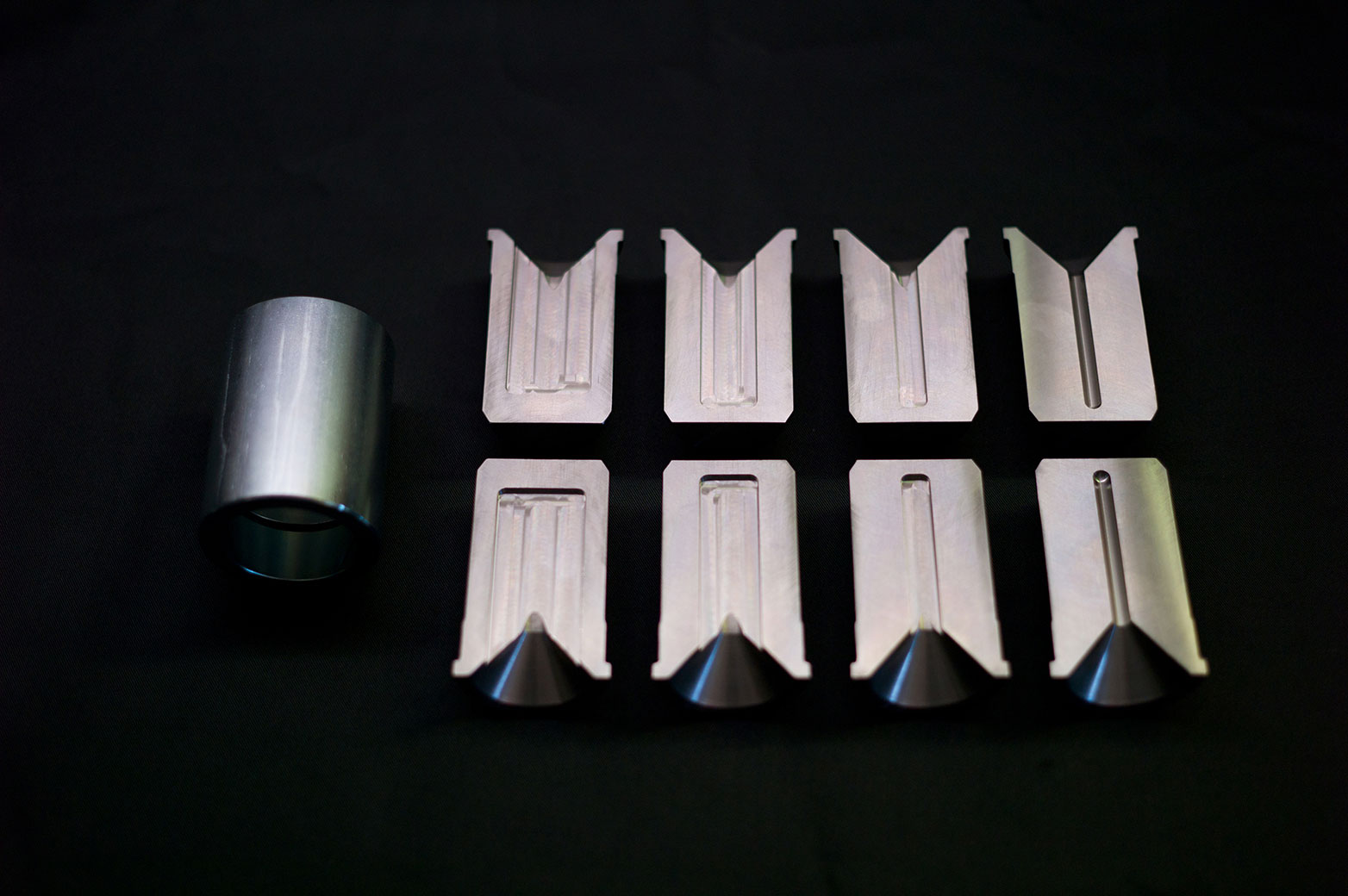

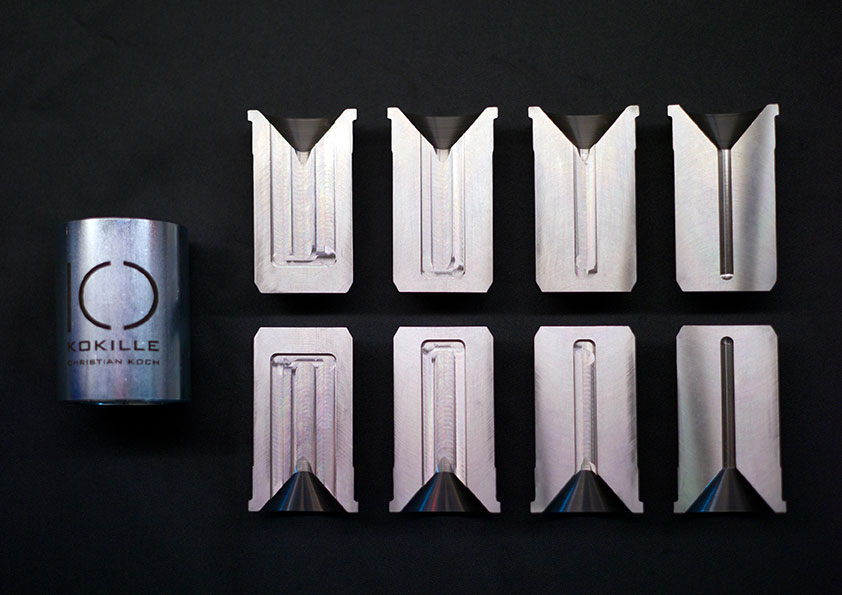

Product information "Sheet metal casting 20 x 55 x 5mm"

Developed by goldsmiths for the goldsmith. Made in Austria.

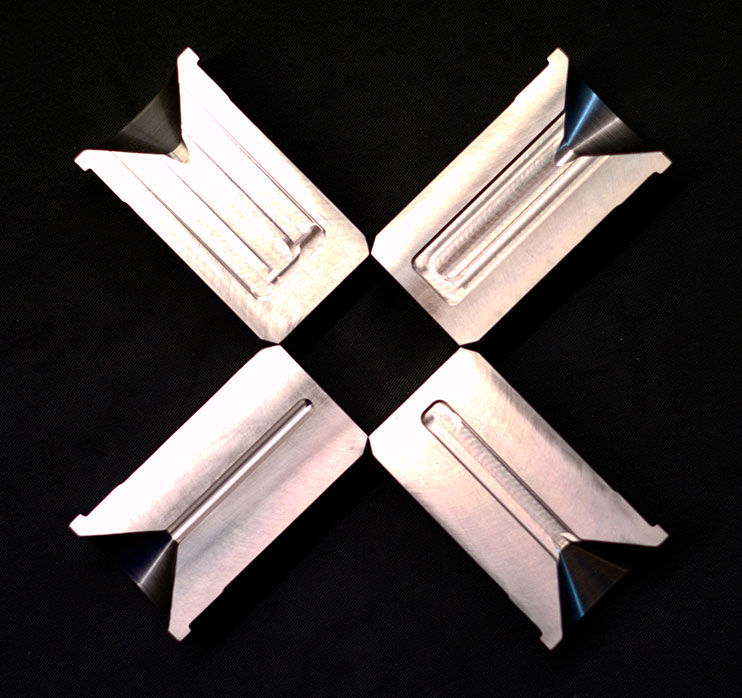

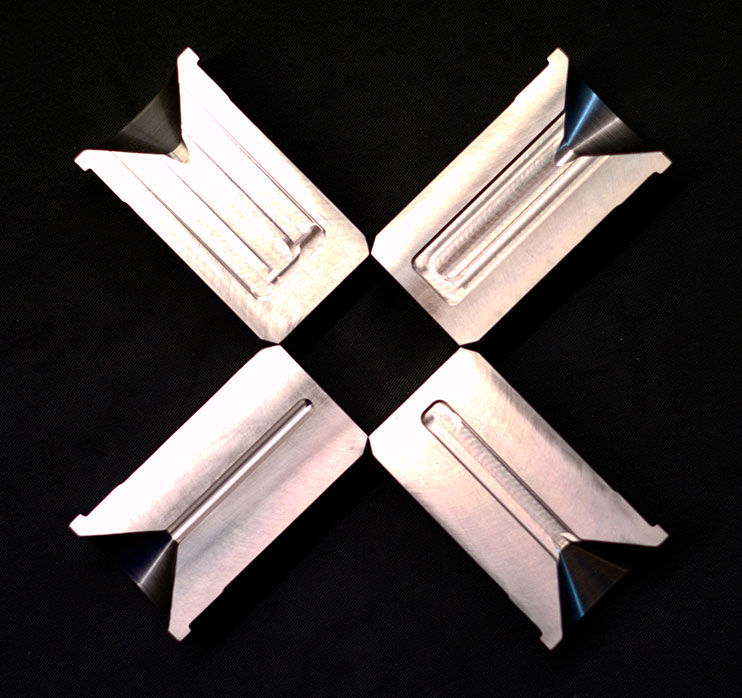

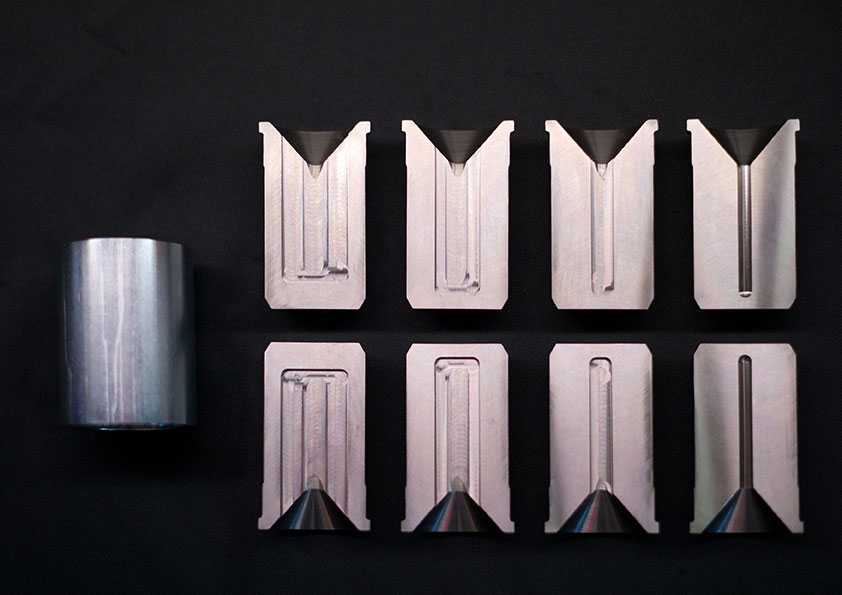

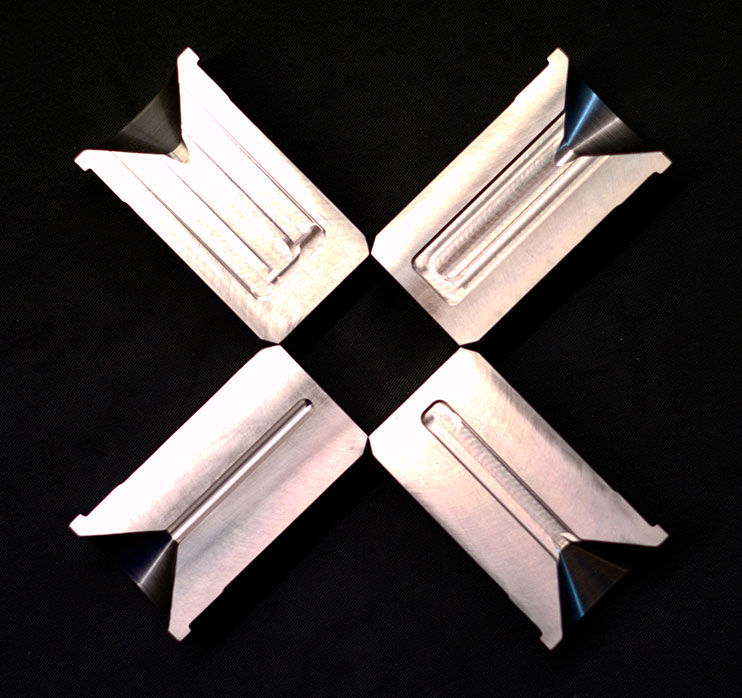

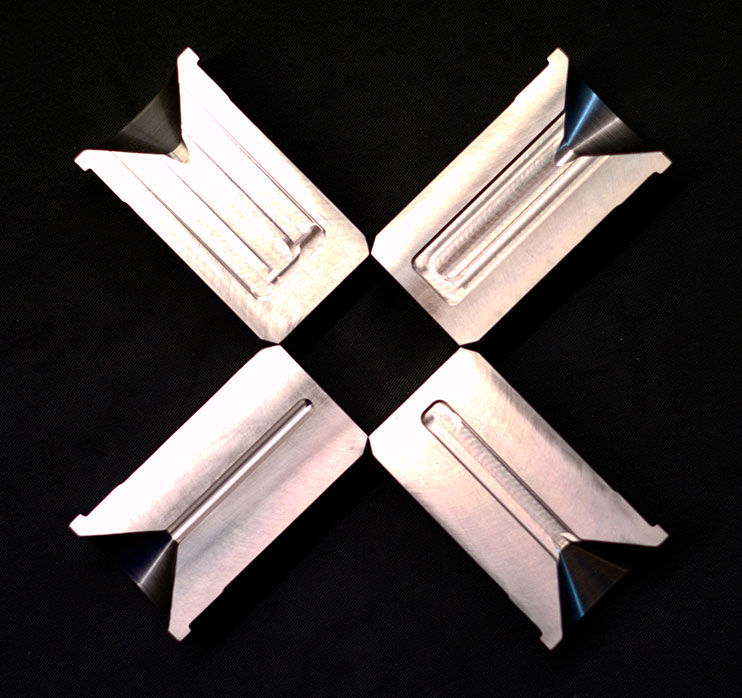

The well thought-out sprue for the manufacture of semi-finished products.

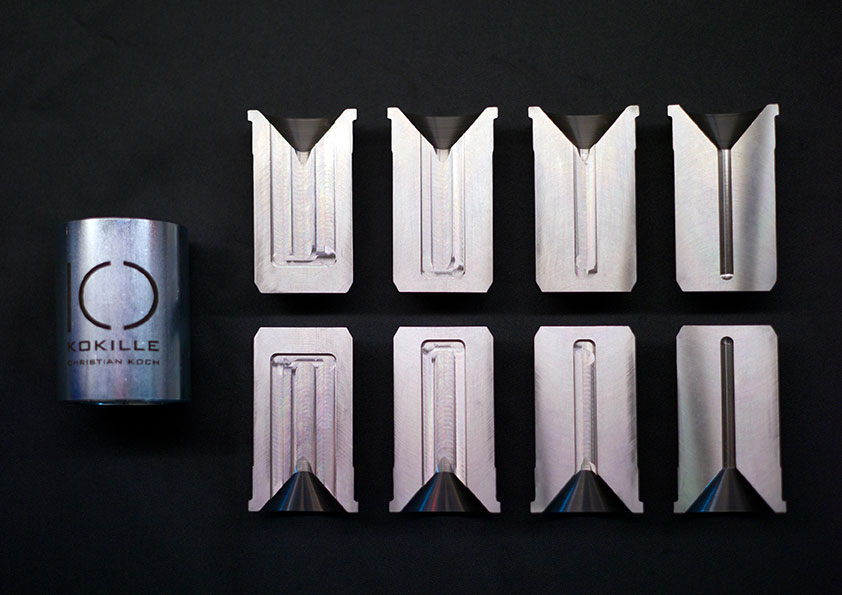

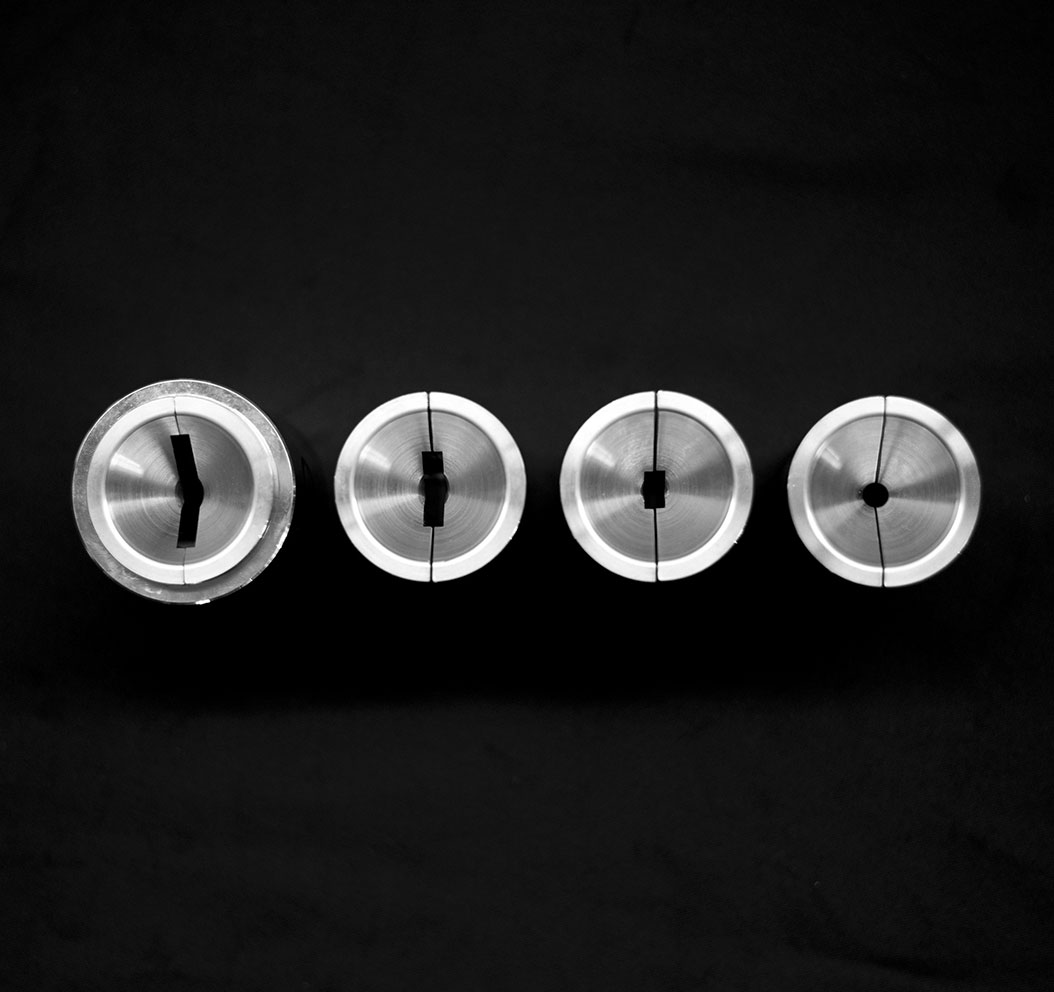

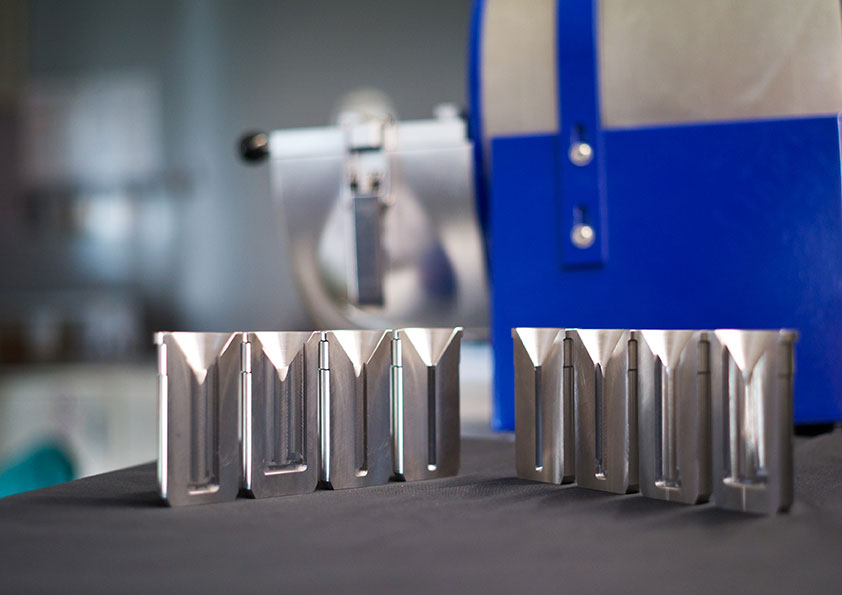

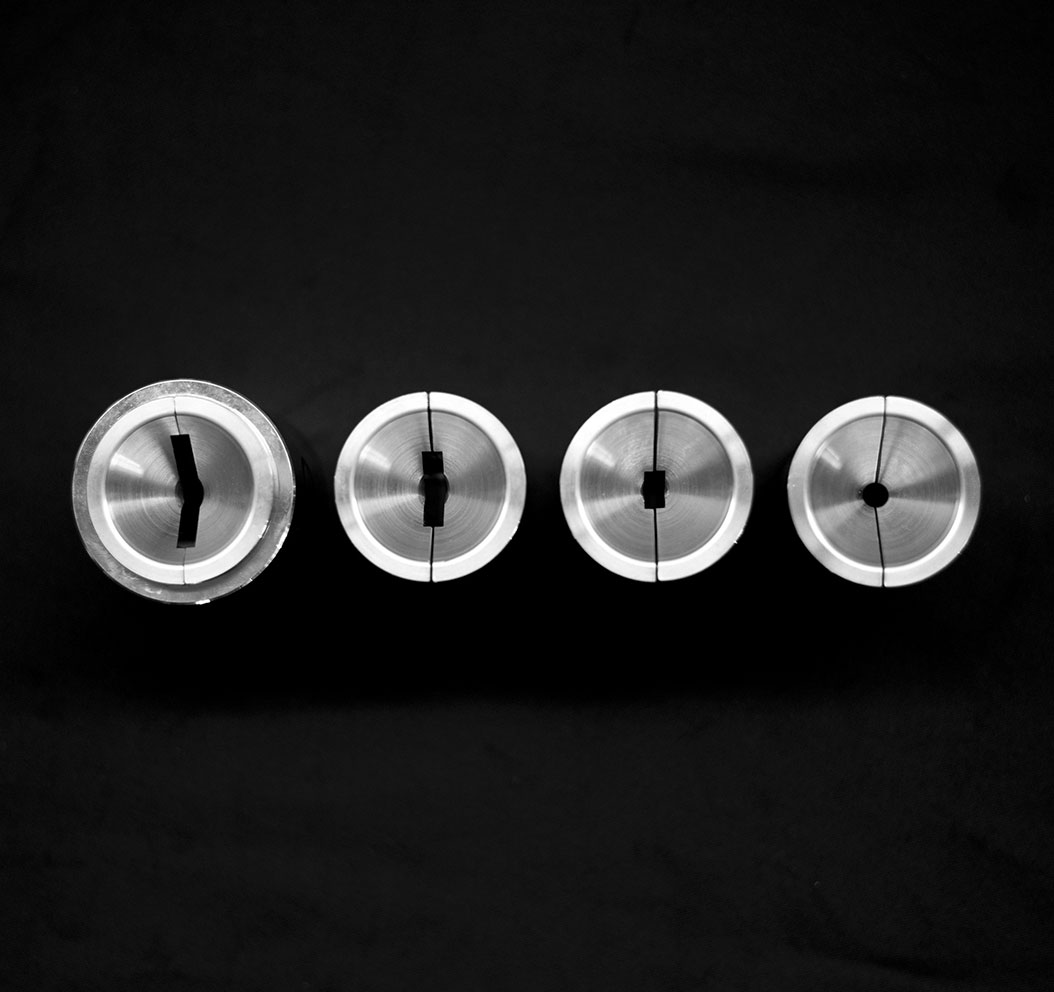

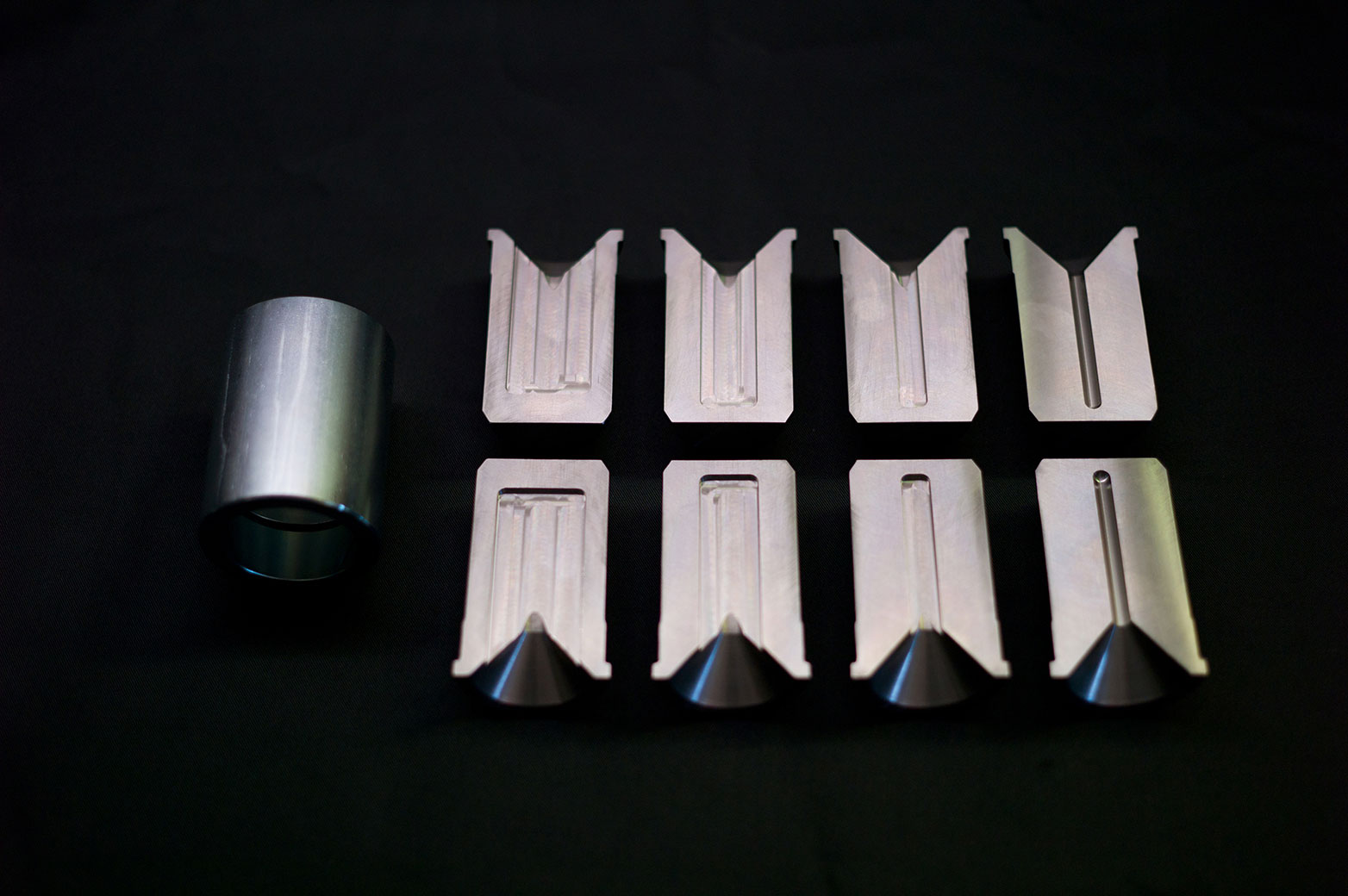

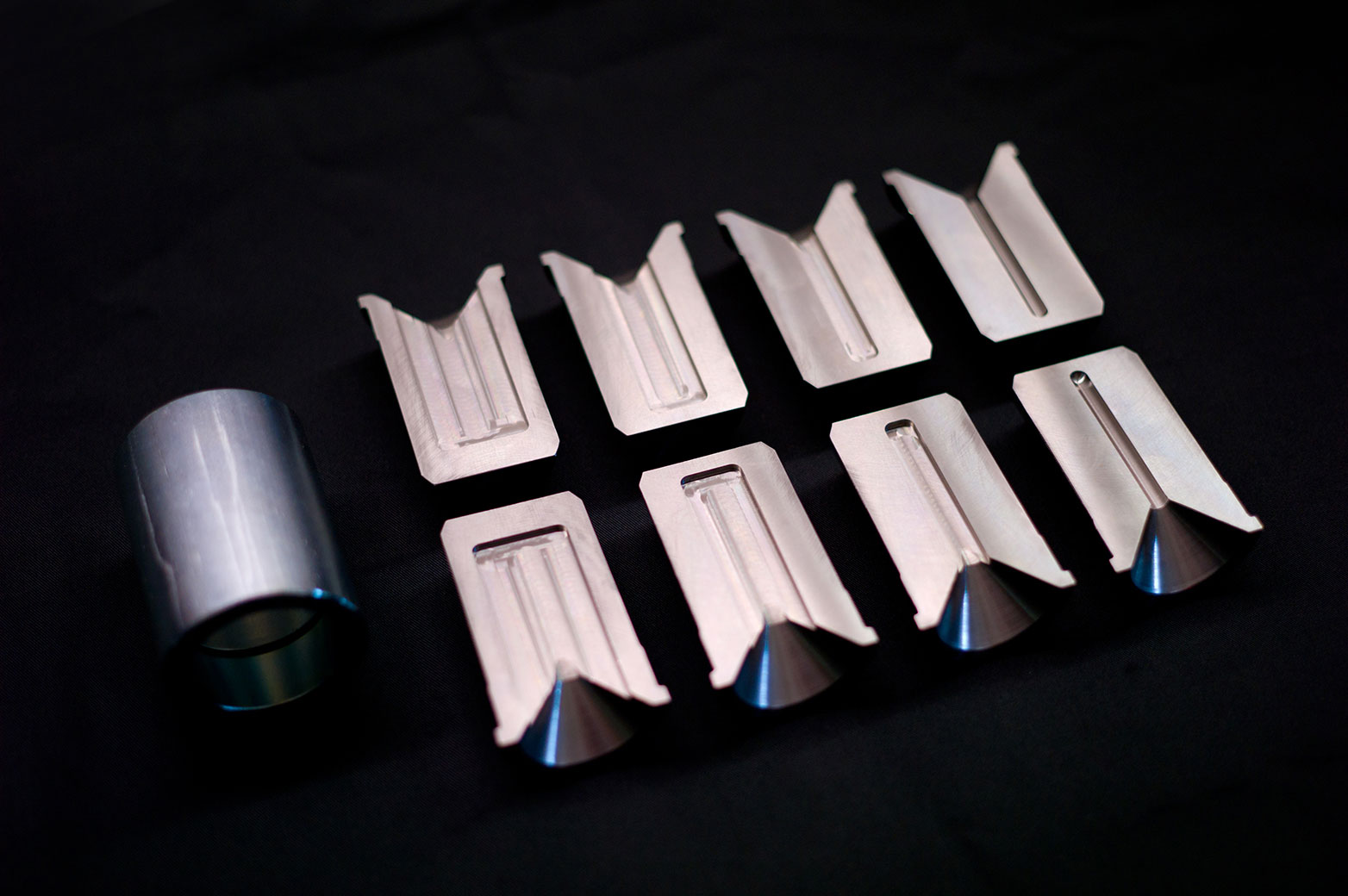

The exclusive KC mold is a sprue that consists of two cylinder halves and a metal sleeve. Double O-rings are worked into this metal sleeve, which press the two cylinder halves together. The cylinder halves are turned offset. Thanks to this deliberate edge, the halves remain stable in shape.

• Manufactured in the Stubai Valley, Austria, which is known around the world for its outstanding quality in metalworking and toolmaking.

ADVANTAGES OF OUR CHILLES:

• Very large pouring funnel (Ø 4cm)

• No clamps or screws

• Simple and quick opening and closing

• Solid and robustly built

• Rapid solidification of the melt = finer-grain structure

• Rounded ends

• Cylinder halves made of high quality stainless steel

The specialty - and thus the greatest advantage of our Flume molds - is

• COMPATIBILITY WITH (ALMOST) ALL CASTING PLANTS:

Due to the cylindrical shape, the mold can be easily inserted or placed. It opens up new possibilities for optimizing the work process, increasing the quality of the semi-finished products and also reducing the "time" cost factor.

• Extremely fast melting through induction etc.

• Control of the temperature of the melt

• Melting in a protective atmosphere = no oxidations

• Enormous time savings!

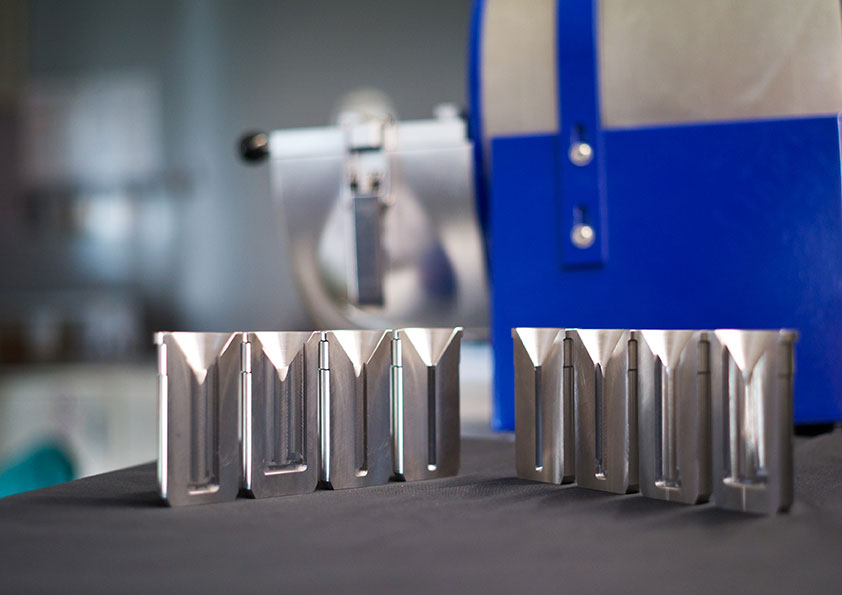

EXECUTIONS

• WIRE CASTING available in Ø 6mm (reference 359030) - approx. 25gr. 750/000

• WIRE INLET available in Ø 8mm (reference 359031) - approx. 40gr. 750/000

• SHEET INLET available in 10 x 55 x 5mm (reference 359032) - approx. 40gr. 750/000

• SHEET CASTING available in 20 x 55 x 5mm (reference 359033) - approx. 85gr. 750/000

• SHEET CASTING available in 30 x 55 x 5mm (reference 359034) - approx. 110gr. 750/000

Please also order:

• SLEEVE - Reference 359035

All parts are CNC machined; the outer tube into which the inserts are inserted is galvanized and therefore corrosion-resistant. The incorporated O-rings are the only wear parts that have to be replaced every now and then.

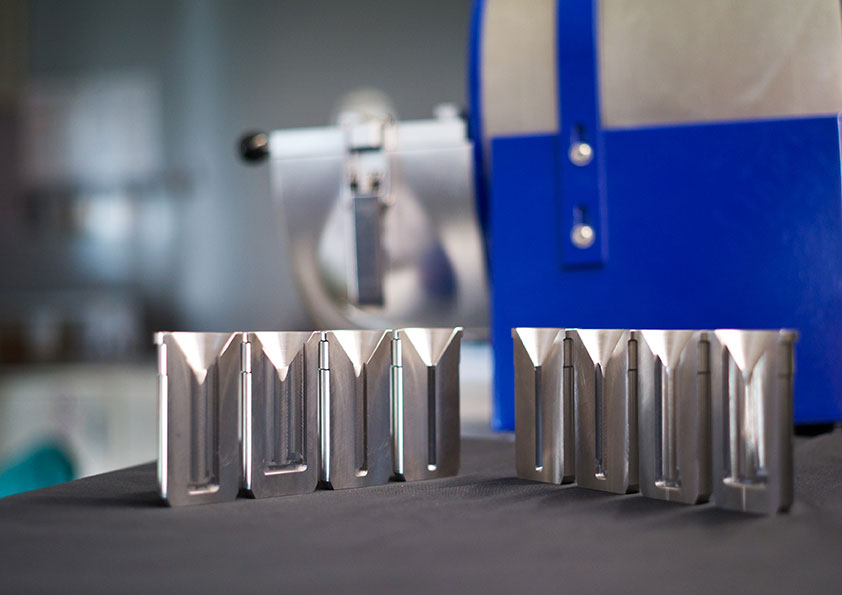

WORTH KNOWING ABOUT THE USE and IDEA OF THE KC-KOKILLEN (from the developer):

"At the beginning of the development it was" only "about being able to cast our own sheets and wires faster, more efficiently and in better quality with the help of our Indutherm MC 15+ Month saved without the disadvantages of conventional molds.

By omitting clamps or screws, the KC mold is suitable for almost all casting machines. Especially for the MC series an optimal addition through and through. The cylinder halves are made of high quality stainless steel, the sleeve of galvanized steel. Two embedded O-rings complete the system. They press the cylinder halves together and hold them in the sleeve. This enables both quick and easy opening and closing. The pouring funnel with a diameter of 4 cm is not only a boon for newcomers to the profession. No spilling or the famous “shivering” into the mold.

If the customer has a casting plant, they will be able to produce better semi-finished products themself with the help of the KC mold. Alloying or melting normally takes approx. 10 minutes (+/- 3 minutes) (without any other aids).

Gloves on, protective goggles on, turn on propane gas, place the mold correctly, set the flame, add borax, melt, wait until the fine gold and silver are liquid, add copper, continue heating. When the melt is homogeneous, pour into the mold. Take off your glasses, take off your gloves, twist everything off and put the cast sheet metal / wire into the stain to remove borax residues. With the KC mold, this takes a maximum of 5 minutes.

Insert the middle holder, insert the mold and melt + pour into the mold. This includes the time in which the system melts. The actual active process is significantly shorter. A mold pays for itself after 6 months at the latest if it is only used 8 times a month. We use them about 2 times a day (3 goldsmiths).

The O-rings should always be lightly oiled - this makes inserting and removing especially easy. If the cylinder halves no longer close or jam when inserting (corners hit, etc.), simply pull them off on a plane surface. After many years of use, our molds are still ready for use as they were on the first day. Should it happen that the molds are significantly abraded, then thicker O-rings can be used without any problems.

We coat the mold with silicone spray, but preferably with a boron nitride spray. When properly applied (degreased beforehand), this layer will last for weeks to months."

In our range:

• BORNIDRID-SPRAY / CERAMIC PASTE - MADE IN GERMANY - LIQUI MOLY - Reference 359038

• SILICONE SPRAY - MADE IN GERMANY - LIQUI MOLY - Reference 359039

PLEASE ALSO NOTE THE DOCUMENT ON THE CAPACITY IN THE "DOCUMENTS" TAB ON THIS PAGE

The well thought-out sprue for the manufacture of semi-finished products.

The exclusive KC mold is a sprue that consists of two cylinder halves and a metal sleeve. Double O-rings are worked into this metal sleeve, which press the two cylinder halves together. The cylinder halves are turned offset. Thanks to this deliberate edge, the halves remain stable in shape.

• Manufactured in the Stubai Valley, Austria, which is known around the world for its outstanding quality in metalworking and toolmaking.

ADVANTAGES OF OUR CHILLES:

• Very large pouring funnel (Ø 4cm)

• No clamps or screws

• Simple and quick opening and closing

• Solid and robustly built

• Rapid solidification of the melt = finer-grain structure

• Rounded ends

• Cylinder halves made of high quality stainless steel

The specialty - and thus the greatest advantage of our Flume molds - is

• COMPATIBILITY WITH (ALMOST) ALL CASTING PLANTS:

Due to the cylindrical shape, the mold can be easily inserted or placed. It opens up new possibilities for optimizing the work process, increasing the quality of the semi-finished products and also reducing the "time" cost factor.

• Extremely fast melting through induction etc.

• Control of the temperature of the melt

• Melting in a protective atmosphere = no oxidations

• Enormous time savings!

EXECUTIONS

• WIRE CASTING available in Ø 6mm (reference 359030) - approx. 25gr. 750/000

• WIRE INLET available in Ø 8mm (reference 359031) - approx. 40gr. 750/000

• SHEET INLET available in 10 x 55 x 5mm (reference 359032) - approx. 40gr. 750/000

• SHEET CASTING available in 20 x 55 x 5mm (reference 359033) - approx. 85gr. 750/000

• SHEET CASTING available in 30 x 55 x 5mm (reference 359034) - approx. 110gr. 750/000

Please also order:

• SLEEVE - Reference 359035

All parts are CNC machined; the outer tube into which the inserts are inserted is galvanized and therefore corrosion-resistant. The incorporated O-rings are the only wear parts that have to be replaced every now and then.

WORTH KNOWING ABOUT THE USE and IDEA OF THE KC-KOKILLEN (from the developer):

"At the beginning of the development it was" only "about being able to cast our own sheets and wires faster, more efficiently and in better quality with the help of our Indutherm MC 15+ Month saved without the disadvantages of conventional molds.

By omitting clamps or screws, the KC mold is suitable for almost all casting machines. Especially for the MC series an optimal addition through and through. The cylinder halves are made of high quality stainless steel, the sleeve of galvanized steel. Two embedded O-rings complete the system. They press the cylinder halves together and hold them in the sleeve. This enables both quick and easy opening and closing. The pouring funnel with a diameter of 4 cm is not only a boon for newcomers to the profession. No spilling or the famous “shivering” into the mold.

If the customer has a casting plant, they will be able to produce better semi-finished products themself with the help of the KC mold. Alloying or melting normally takes approx. 10 minutes (+/- 3 minutes) (without any other aids).

Gloves on, protective goggles on, turn on propane gas, place the mold correctly, set the flame, add borax, melt, wait until the fine gold and silver are liquid, add copper, continue heating. When the melt is homogeneous, pour into the mold. Take off your glasses, take off your gloves, twist everything off and put the cast sheet metal / wire into the stain to remove borax residues. With the KC mold, this takes a maximum of 5 minutes.

Insert the middle holder, insert the mold and melt + pour into the mold. This includes the time in which the system melts. The actual active process is significantly shorter. A mold pays for itself after 6 months at the latest if it is only used 8 times a month. We use them about 2 times a day (3 goldsmiths).

The O-rings should always be lightly oiled - this makes inserting and removing especially easy. If the cylinder halves no longer close or jam when inserting (corners hit, etc.), simply pull them off on a plane surface. After many years of use, our molds are still ready for use as they were on the first day. Should it happen that the molds are significantly abraded, then thicker O-rings can be used without any problems.

We coat the mold with silicone spray, but preferably with a boron nitride spray. When properly applied (degreased beforehand), this layer will last for weeks to months."

In our range:

• BORNIDRID-SPRAY / CERAMIC PASTE - MADE IN GERMANY - LIQUI MOLY - Reference 359038

• SILICONE SPRAY - MADE IN GERMANY - LIQUI MOLY - Reference 359039

PLEASE ALSO NOTE THE DOCUMENT ON THE CAPACITY IN THE "DOCUMENTS" TAB ON THIS PAGE