-

Tools/supplies

-

Drilling, polishing, grinding

-

Turning

-

Facilities, compressed air and vacuum

-

Goldsmith special tools/GRS

-

Small tools

- Soldering, melting, casting, welding

-

Measuring and testing

-

Surface treatment

-

Clean, dry, turning, sawing

-

CAD-software / software

-

Watchmaker tools

-

Sales and workshop tools

-

3D Werkzeuge & Reinigung

-

Drilling, polishing, grinding

Pickling unit

Product number:

4442011

Packaging Unit:

1

From Stock

| Article name: | Pickling unit \Deoxor\ |

|---|---|

| Content: | 0,60 |

| Manufacturer name: | DEOXOR |

| Temperature °C.: | 70 °C |

| Unit content: | ml |

Manufacturer Informations

Name: Helmut Klein GmbH

Street: Fritz-Neuert-Str. 31

City: 75181 Pforzheim

Country: DE

Email: info@klein-messtechnik.de

Phone: 0049-7231-953590

0 of 0 reviews

Login

No reviews found. Be the first to share your insights.

Accessoires (required)

slide 6 to 8 of 5

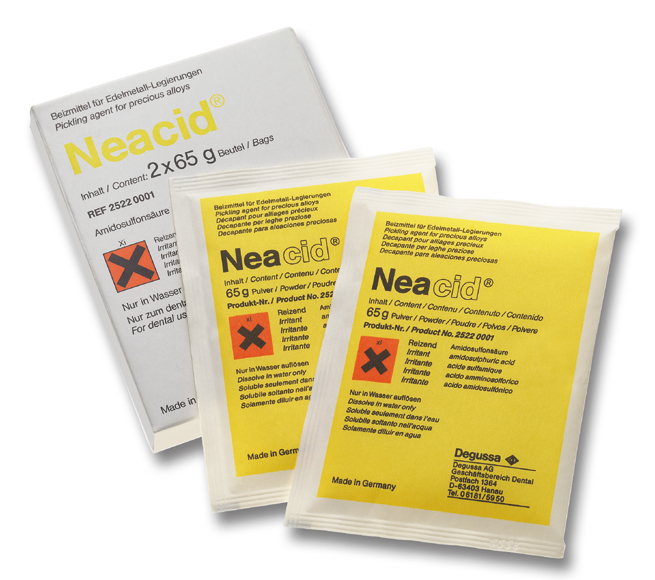

To remove oxidation and flux residues from solder joints on all coloured gold and palladium white gold alloys of 14 and 18 ct. Mixing ratio 65 g in 250 ml of water.

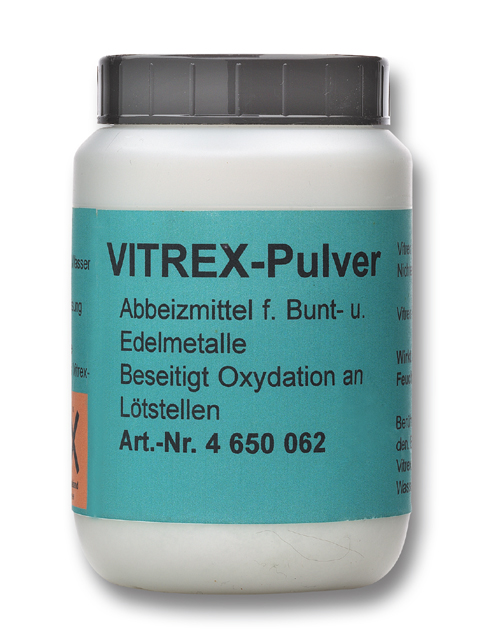

The VITREX formula:

- For removing oxidations and flux residues from soldering points on all non-ferrous and precious metals.

The VITREX plus:

The particular advantage of our Vitrex powder is the constant activity. It works to the last drop. Vitrex removes oxides and flux residues from all precious and non-ferrous metals. Vitrex is unsuitable for iron.

The VITREX application:

- Prepare the solution: approx. 32g powder in approx. 250ml. Tap water as a supersaturated solution (approx. 50g to 400ml)

- Immerse the metal to be cleaned in the solution.

- Rinse with water after removal.

The VITREX tip:

- A solution heated to around 50 ° -70 ° C accelerates cleaning.

- The agent is suitable for pickling devices with polypropylene or stainless steel tubs.

The VITREX advisor:

When making your own stain, make sure that the acid is added to the water. This releases a considerable amount of heat. If you were to proceed the other way around, i.e. pour the water into the acid, the water droplets poured in could immediately heat up to the boiling point, and when they evaporate, they would splash out explosively parts of the acid. So please pay attention to the following: FIRST THE WATER, THEN THE ACID!

- The powder / solution is corrosive in combination with moisture

- Avoid contact with skin and eyes

- In the event of possible contact or wetting of the eyes, rinse immediately with plenty of water

To remove oxidation and flux residues from solder joints on all gold and silver alloys. Mixing ratio 30 g in 250 ml of water.

Content:

1000

Ready to use mordant for removing oxidation and flux residues from solder joints on all non-ferrous and precious metals. For yellow gold alloys 333, pickling will not create reddish deposits. Ultra-Poon-S can be diluted 1:1 with water and can even be used cold as a de-oxidiser. Unlike all other mordants, this product can be disposed off in the sewer system.

Content:

5000

Ready to use mordant for removing oxidation and flux residues from solder joints on all non-ferrous and precious metals. For yellow gold alloys 333, pickling will not create reddish deposits. Ultra-Poon-S can be diluted 1:1 with water and can even be used cold as a de-oxidiser. Unlike all other mordants, this product can be disposed off in the sewer system.

To remove oxidation and flux residues from solder joints on all coloured gold and palladium white gold alloys of 14 and 18 ct. Mixing ratio 65 g in 250 ml of water.

The VITREX formula:

- For removing oxidations and flux residues from soldering points on all non-ferrous and precious metals.

The VITREX plus:

The particular advantage of our Vitrex powder is the constant activity. It works to the last drop. Vitrex removes oxides and flux residues from all precious and non-ferrous metals. Vitrex is unsuitable for iron.

The VITREX application:

- Prepare the solution: approx. 32g powder in approx. 250ml. Tap water as a supersaturated solution (approx. 50g to 400ml)

- Immerse the metal to be cleaned in the solution.

- Rinse with water after removal.

The VITREX tip:

- A solution heated to around 50 ° -70 ° C accelerates cleaning.

- The agent is suitable for pickling devices with polypropylene or stainless steel tubs.

The VITREX advisor:

When making your own stain, make sure that the acid is added to the water. This releases a considerable amount of heat. If you were to proceed the other way around, i.e. pour the water into the acid, the water droplets poured in could immediately heat up to the boiling point, and when they evaporate, they would splash out explosively parts of the acid. So please pay attention to the following: FIRST THE WATER, THEN THE ACID!

- The powder / solution is corrosive in combination with moisture

- Avoid contact with skin and eyes

- In the event of possible contact or wetting of the eyes, rinse immediately with plenty of water

To remove oxidation and flux residues from solder joints on all gold and silver alloys. Mixing ratio 30 g in 250 ml of water.

Content:

1000

Ready to use mordant for removing oxidation and flux residues from solder joints on all non-ferrous and precious metals. For yellow gold alloys 333, pickling will not create reddish deposits. Ultra-Poon-S can be diluted 1:1 with water and can even be used cold as a de-oxidiser. Unlike all other mordants, this product can be disposed off in the sewer system.

Content:

5000

Ready to use mordant for removing oxidation and flux residues from solder joints on all non-ferrous and precious metals. For yellow gold alloys 333, pickling will not create reddish deposits. Ultra-Poon-S can be diluted 1:1 with water and can even be used cold as a de-oxidiser. Unlike all other mordants, this product can be disposed off in the sewer system.

To remove oxidation and flux residues from solder joints on all coloured gold and palladium white gold alloys of 14 and 18 ct. Mixing ratio 65 g in 250 ml of water.

The VITREX formula:

- For removing oxidations and flux residues from soldering points on all non-ferrous and precious metals.

The VITREX plus:

The particular advantage of our Vitrex powder is the constant activity. It works to the last drop. Vitrex removes oxides and flux residues from all precious and non-ferrous metals. Vitrex is unsuitable for iron.

The VITREX application:

- Prepare the solution: approx. 32g powder in approx. 250ml. Tap water as a supersaturated solution (approx. 50g to 400ml)

- Immerse the metal to be cleaned in the solution.

- Rinse with water after removal.

The VITREX tip:

- A solution heated to around 50 ° -70 ° C accelerates cleaning.

- The agent is suitable for pickling devices with polypropylene or stainless steel tubs.

The VITREX advisor:

When making your own stain, make sure that the acid is added to the water. This releases a considerable amount of heat. If you were to proceed the other way around, i.e. pour the water into the acid, the water droplets poured in could immediately heat up to the boiling point, and when they evaporate, they would splash out explosively parts of the acid. So please pay attention to the following: FIRST THE WATER, THEN THE ACID!

- The powder / solution is corrosive in combination with moisture

- Avoid contact with skin and eyes

- In the event of possible contact or wetting of the eyes, rinse immediately with plenty of water

To remove oxidation and flux residues from solder joints on all gold and silver alloys. Mixing ratio 30 g in 250 ml of water.

Content:

1000

Ready to use mordant for removing oxidation and flux residues from solder joints on all non-ferrous and precious metals. For yellow gold alloys 333, pickling will not create reddish deposits. Ultra-Poon-S can be diluted 1:1 with water and can even be used cold as a de-oxidiser. Unlike all other mordants, this product can be disposed off in the sewer system.

Content:

5000

Ready to use mordant for removing oxidation and flux residues from solder joints on all non-ferrous and precious metals. For yellow gold alloys 333, pickling will not create reddish deposits. Ultra-Poon-S can be diluted 1:1 with water and can even be used cold as a de-oxidiser. Unlike all other mordants, this product can be disposed off in the sewer system.

Product information "Pickling unit"

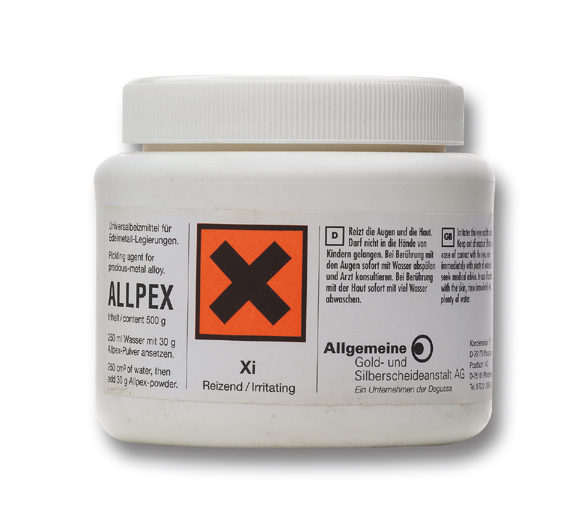

This unit can heat pickling agents, such as Allpex, Neacid, Vitrex, or up to 10% sulfuric acid.

Modern and convenient unit for efficient stripping of workpieces up to the size of glasses frames.

- Electrically heated, thermostatically controlled

- Impact-resistant polypropylene housing

- Temperature and acid resistant

- Removable basket (190 x 80 mm) br

- Easy swivelling of the workpieces into the pickling liquid

- Yellow indicator light indicates reaching operating temperature

230 V, 50 Hz.

Modern and convenient unit for efficient stripping of workpieces up to the size of glasses frames.

- Electrically heated, thermostatically controlled

- Impact-resistant polypropylene housing

- Temperature and acid resistant

- Removable basket (190 x 80 mm) br

- Easy swivelling of the workpieces into the pickling liquid

- Yellow indicator light indicates reaching operating temperature

230 V, 50 Hz.