-

Tools/supplies

-

Drilling, polishing, grinding

-

Turning

-

Facilities, compressed air and vacuum

-

Goldsmith special tools/GRS

-

Small tools

-

Soldering, melting, casting, welding

-

Measuring and testing

-

Surface treatment

-

Clean, dry, turning, sawing

-

CAD-software / software

-

Watchmaker tools

- Sales and workshop tools

-

3D Werkzeuge & Reinigung

-

Drilling, polishing, grinding

-

Craft & creative

-

Advent calendar

-

Everything about molding

-

Everything about wood

-

Handicraft sets and tools

-

Poker work

-

Encaustic

-

Experiments

-

Colors & polish

-

Galvanizing

-

(Glass) Engraving

-

Kerzen gießen

-

Adhesives

-

Crib construction

-

Jigsaw

-

Soldering & welding

-

Model kits

-

Collector models

-

Sharpening

-

Writing instruments

-

Soap casting

-

teifoc stone building sets

-

Gilding

-

Tools & machines

-

Pouring tin - material and equipment

-

Advent calendar

slide 2 of 7

slide 1 to 5 of 7

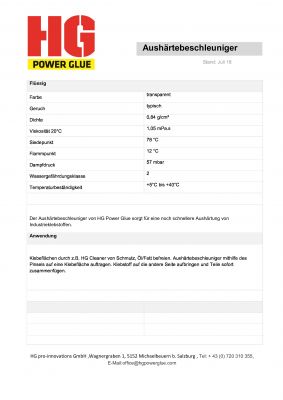

The weld out of the bottle - Activator for brushing (curing accelerator) - 15ml

Product number:

345867

Packaging Unit:

1

From Stock

Dangerous goods information

| Description | Aceton, Lösung |

|---|---|

| Dangerous goods from: | 101 |

| Dangerous goods class: | 3 |

| UN-Nummer: | 1090 |

| Dangerous goods information: |

| Application: | Activator for brushes (curing accelerator) |

|---|---|

| Article name: | The weld out of the bottle |

| Brand: | Die Schweißnaht |

| Content: | 15,00 |

| Dangerous goods from quantity: | 101 |

| Manufacturer name: | HG Power Glue |

| Special feature: | for smallest connections |

| Unit content: | ml |

Manufacturer Informations

Name: HG pro-innovations GmbH

Street: Wagnergraben 1

City: 5152 Dorfbeuern

Country: AT

Email: office@hgpowerglue.com

Phone: +43 (0) 720 310 355

0 of 0 reviews

Login

No reviews found. Be the first to share your insights.

Accessoires (optional)

slide 5 to 7 of 7

HG-activator - The hardening accelerator for professionals

industrial adhesives stick very efficient due to complete absence of oxygen. This is obtained by contact pressure. However, certain materials such as porcelain, stone, tile, wood or ceramic need for bonding without granules often until they are completely cured several hours. Or is very porous, tiny or two non-fit surfaces, so you can not exert a contact pressure. In these cases, the HG-activator causes an extremely rapid bonding. Here our hardening accelerator is specifically tailored to our HG-industrial adhesive. After a few seconds, the breaking point is glued by hand.

The application of the HG-activator

1. Application of the activator

, the curing accelerator may both before and also be applied after the bonding. In the application before bonding one side of the fracture site with the activator is sprayed, the coated other with glue before the two parts are joined together. If the activator spray applied only after the gluing, is previously painted only on one side of the crack HG-industrial adhesive. The two objects were then joined together, the splice is wetted with the hardening accelerator.

2. CURING LET

After a few seconds, the breaking point is glued by hand.

By HG Cleaner Clean and remove the remains

Our highly concentrated cleaner suitable for two applications. First, it cleans as pretreatment surfaces to be bonded from contamination, he removed to another reliably and playing stubborn adhesive residue. Can be made a lasting and stable connection Only through this purification process.

What can you remove the cleaner

the surface of the fracture must be cleaned for a successful bonding of any kind of pollution. These include oil, grease, moisture, rust, dust and other contaminants. In addition, from the cleaner quickly and easily adhesive residue on the surface of the materials to be bonded or hardened remains on the skin, textiles or the tabletop.

The application of HG Cleaners

1. COMPATIBILITY CHECK

Before applying the highly concentrated cleaner that materials should be checked strictly on their EMI. This is best to test a tiny amount of the surface and wipe with an undesired reaction immediately.

2. OPTIONAL: GLUE REMAINS TO REMOVE

case before bonding the fracture adhesive residue must be removed yet, a few drops of the cleaner be applied directly to the glue residue. The cleaner must move in a few minutes and liquefied residues. These can be easily removed with a clean cloth.

3. BASIC CLEANING

For cleaning the breaking point are only applied a few drops of the cleaner at the point where then is stuck. In order to achieve strong adhesion values, it is essential to use a clean cloth and completely remove the cleaner along with dirt. Any contamination degrades the stability of the adhesive bond.

Content:

1x Rugged portable case

1x The weld from the bottle (20g industrial adhesive + 40g granulate)

1x HG-Cleaner / Cleaner and Adhesive Remover (20ml)

1x HG-primer / adhesion promoter for difficult to bond plastics (15ml)

1x HG-activator for brushes / hardening accelerator (15ml)

1x HG activator spray / curing accelerator (200ml)

1x HG-Epoxy Stick / Universal Knetmetall (56g)

Your 4 main benefits at a glance:

QUALITY GIFT: The case is the perfect gift for Father's Day, whether for campers, mechanics, model builders, or for a family man. It is filled with everything a home improvement needed in an emergency.

THE BEST CHOICE FOR COUNTLESS REPAIRS: Whether broken shoe soles, broken china, leaking tanks or extreme breaking points on the car, motorcycle or children's toy: with this case, you always have everything you need on site.

PREMIUM QUALITY: The case is equipped with high-quality adhesive products that you have on hand the right product for almost any application allow.

LIGHTWEIGHT AND PORTABLE: The rugged case is simple and easy to carry, so you always have everything at hand in case of repair.

Der praktische Stick für die schnelle Reparatur!

Montieren, kleben und abdichten mit dem HG Epoxy Stick

Der Epoxy Stick ist eine Reparaturknetmasse, mit der du Ausbesserungsarbeiten schnell und einfach durchführst.

Ein paar Minuten mit der Hand geknetet und diese unscheinbare Masse verwandelt sich in ein regelrechtes Universalgenie.

Nach nur 5 Minuten ist das Material so fest, dass es sich kaum noch verformen lässt. Nach 24 Stunden ist die Masse so hart, dass man hineinbohren oder sogar ein Gewinde hineinschneiden könnte.

Wofür wird das Epoxy eingesetzt?

Der Dübel hält nicht mehr in der Wand? Kein Problem! Die Masse ein paar Minuten kneten und anschließend samt Dübel in das Loch pressen – fertig! Du hast ein Loch in der Regentonne? Kein Ding! Das Epoxy klebt sogar unter Wasser und dichtet deine Tonne wieder ab. Du sparst dir aufwendige Reparaturarbeiten.

Du siehst also: Der Kreativität, das Epoxy sinnvoll einzusetzen, sind keine Grenzen gesetzt. Die Knetmasse eignet sich zum Montieren, Befestigen oder Abdichten. Nach dem Aushärten lässt sich die behandelte Stelle ohne Probleme schleifen, lackieren, bohren usw.

Die Reparaturmasse ist abweisend gegen Wasser, Öl, Benzin und viele anderen Chemikalien. Temperaturbereich: -50°C bis +180°C (kurzfristig bis 300°C)

Anwendung:

1. Reinigung

Jeglichen Schmutz, wie Staub und Fett, von der zu behandelnden Oberfläche entfernen.

2. Folie abziehen

Bevor mit der Knetmasse gearbeitet wird, muss die Schutzfolie rückstandslos entfernt werden.

3. Menge bestimmen

Die benötigte Menge abschätzen und mit einem scharfen Messer vom Epoxy-Stick abschneiden.

4. Kneten

Die benötigte Masse manuell mit der Hand kneten, damit sich die Inhaltsstoffe verbinden und eine Polymerverbindung eingehen (Tipp: Dabei Handschuhe tragen). Wenn das Material warm wird und sich verfärbt, bleiben ca. 5 Minuten zur Verarbeitung des Epoxids.

5. Reparieren und aushärten lassen

Die Reparatur, wie z. B. das Abdichten von Löchern oder das Zusammenkleben kaputter Teile, vornehmen. Nach dem Aushärten kann das Material geschliffen, lackiert und angebohrt werden.

345870 - Epoxy-Stick - 56g

• EIN UNIVERSALGENIE: Das HG Epoxy ist eine vielfältig einsetzbare Knetmasse zum Montieren, Kleben und Abdichten.

• HÄLT AUCH UNTER WASSER: Das Epoxy eignet sich hervorragend zum Stopfen von Löchern und Abdichten von Tanks und Behältern.

• BEARBEITBAR: Das Material wird so hart, dass sich die Stelle beliebig bearbeiten lässt. Du kannst sie schleifen, lackieren und anbohren.

Gefahrenhinweis:

ACHTUG. 4,4'-Methylen diphenyldiglycidylether. Reaktionsprodukte von Pentaerythrit, propoxyliertem und 1-Chlor-2,3-

epoxypropan mit Schwefelwasserstoff. Verursacht Hautreizungen. Verursacht schwere Augenreizung.

Kann allergische Hautreaktionen verursachen. Schädlich für Wasserorganismen, mit langfristiger Wirkung.

Ist ärztlicher Rat erforderlich, Verpackung oder Kennzeichnungsetikett bereithalten.

Darf nicht in die Hände von Kindern gelangen. Schutzhandschuhe / Augenschutz / Gesichtsschutz tragen.

Bei Hautreizung oder -ausschlag: Ärztlichen Rat einholen / ärztliche Hilfe hinzuziehen.

BEI KONTAKT MIT DEN AUGEN: Einige Minuten lang behutsam mit Wasser spülen. Eventuell vorhandene

Kontaktlinsen nach Möglichkeit entfernen. Weiter spülen. Bei anhaltender Augenreizung: Ärztlichen Rat einholen / ärztliche

Hilfe hinzuziehen.Inhalt/Behälter gemäß lokalen/nationalen Vorschriften der Entsorgung zuführen.

Enthält epoxidhaltige Verbindungen. Kann allergische Reaktionen hervorrufen.

UFI: 2E00-V04G-D00J-C2C4

Content:

60.00

Suitable for almost all materials

Our adhesive repair kit the called 'the weld out of the bottle' for good reason. The unique mixture of granules and adhesive industry is many times more efficient than conventional adhesives and welded breaks, cracks, cracks, filling holes and gaps as no adhesive before. Our adhesive repair kit is suitable for almost all materials and is extremely durable with proper treatment. The weld is weather-resistant, cold and heat resistance and furthermore waterproof.

Two components for maximum grip

the weld out of the bottle is supplied in two bottles. One containing the extremely strong industrial adhesive HG-Extreme 1.0, the other the specially tuned granules. Only the combination of the two components results in a chemical reaction that unleashed an indescribable adhesive force. Using the granules can be nachmodellieren also broken brackets or threaded back and even grind.

The application of adhesive repair kit

1. cleaning the surface of

the weld seam from the bottle can only achieve their full adhesive strength when the breaking point is prepared. Ideally, one roughens the surface with sandpaper or wire brush on something and cleans it of any dirt. It must find no dust, rust, grease or adhesive residue and adhesive surfaces must be dry. Only then high bond strength can be guaranteed.

2. GRANULAT trickling

Subsequently, the adherend objects are precisely joined at the fracture site and applying a fine layer of granules. The powder height must not exceed 2 mm. Before adding the industrial glue, no chemical reaction occurs.

3. INDUSTRIAL ADHESIVE APPLICATION

Now, the adhesive industry HG-Extreme 1.0 carefully dropped from the second bottle on the granules, impregnated until all the granules in cement. Once the two components come into contact, it comes to chemical reaction and heat is produced. We always recommend to provide both sides of the break point with a weld, for maximum grip. The more the bonding process is repeated, the more stable the compound is.

4. CONNECTION CURING LET

After a few seconds the weld from the bottle reaches its full adhesive strength. Then, when the chemical reaction is finished, the suture can be sanded immediately be drilled or even painted. Depending on the materials, the ultimate strength of the breaking point may vary.

Content:

15.00

Suitable for almost all materials

Our adhesive repair kit the called 'the weld out of the bottle' for good reason. The unique mixture of granules and adhesive industry is many times more efficient than conventional adhesives and welded breaks, cracks, cracks, filling holes and gaps as no adhesive before. Our adhesive repair kit is suitable for almost all materials and is extremely durable with proper treatment. The weld is weather-resistant, cold and heat resistance and furthermore waterproof.

Two components for maximum grip

the weld out of the bottle is supplied in two bottles. One containing the extremely strong industrial adhesive HG-Extreme 1.0, the other the specially tuned granules. Only the combination of the two components results in a chemical reaction that unleashed an indescribable adhesive force. Using the granules can be nachmodellieren also broken brackets or threaded back and even grind.

The application of adhesive repair kit

1. cleaning the surface of

the weld seam from the bottle can only achieve their full adhesive strength when the breaking point is prepared. Ideally, one roughens the surface with sandpaper or wire brush on something and cleans it of any dirt. It must find no dust, rust, grease or adhesive residue and adhesive surfaces must be dry. Only then high bond strength can be guaranteed.

2. GRANULAT trickling

Subsequently, the adherend objects are precisely joined at the fracture site and applying a fine layer of granules. The powder height must not exceed 2 mm. Before adding the industrial glue, no chemical reaction occurs.

3. INDUSTRIAL ADHESIVE APPLICATION

Now, the adhesive industry HG-Extreme 1.0 carefully dropped from the second bottle on the granules, impregnated until all the granules in cement. Once the two components come into contact, it comes to chemical reaction and heat is produced. We always recommend to provide both sides of the break point with a weld, for maximum grip. The more the bonding process is repeated, the more stable the compound is.

4. CONNECTION CURING LET

After a few seconds the weld from the bottle reaches its full adhesive strength. Then, when the chemical reaction is finished, the suture can be sanded immediately be drilled or even painted. Depending on the materials, the ultimate strength of the breaking point may vary.

here are plastics on the market, here you will be really mad if you try to glue them. This is due to the increased wax layer of these plastics these include, for example, PE or PP. (Like installed in children's toys, lunch boxes, etc.)

If you try to glue such plastics without a primer, it only achieved a slight but no liability proper bonding.

With this primer you can even wax-containing materials such as PE or PP permanently to bond again and bombproof together.

Our advice to you:

We recommend this adhesive to each weld from the bottle - the there comes a time where you encounter such plastics - and without these primers it is not possible to glue them successfully.

PS: The primer has no expiration date, and is even cheaper by 20% in a set with 'the weld oit of the bottle'.

1. roughen surface & PRIMER APPLICATION

In order for feeding the liquid primer deep, it is important to roughen the surface to be bonded something. A fine primer layer is then applied directly to the breaking point by means of the brush. The liquid then changed chemically the surface structure.

2. BONDING PROCESS PERFORM

After a few seconds, the HG-primer has completed his work and evaporates. Now the actual bonding process can be carried out as usual. It should be noted that after applying the primer, the actual ultimate strength of the bond is reached after 24 hours.

HG-activator - The hardening accelerator for professionals

industrial adhesives stick very efficient due to complete absence of oxygen. This is obtained by contact pressure. However, certain materials such as porcelain, stone, tile, wood or ceramic need for bonding without granules often until they are completely cured several hours. Or is very porous, tiny or two non-fit surfaces, so you can not exert a contact pressure. In these cases, the HG-activator causes an extremely rapid bonding. Here our hardening accelerator is specifically tailored to our HG-industrial adhesive. After a few seconds, the breaking point is glued by hand.

The application of the HG-activator

1. Application of the activator

, the curing accelerator may both before and also be applied after the bonding. In the application before bonding one side of the fracture site with the activator is sprayed, the coated other with glue before the two parts are joined together. If the activator spray applied only after the gluing, is previously painted only on one side of the crack HG-industrial adhesive. The two objects were then joined together, the splice is wetted with the hardening accelerator.

2. CURING LET

After a few seconds, the breaking point is glued by hand.

By HG Cleaner Clean and remove the remains

Our highly concentrated cleaner suitable for two applications. First, it cleans as pretreatment surfaces to be bonded from contamination, he removed to another reliably and playing stubborn adhesive residue. Can be made a lasting and stable connection Only through this purification process.

What can you remove the cleaner

the surface of the fracture must be cleaned for a successful bonding of any kind of pollution. These include oil, grease, moisture, rust, dust and other contaminants. In addition, from the cleaner quickly and easily adhesive residue on the surface of the materials to be bonded or hardened remains on the skin, textiles or the tabletop.

The application of HG Cleaners

1. COMPATIBILITY CHECK

Before applying the highly concentrated cleaner that materials should be checked strictly on their EMI. This is best to test a tiny amount of the surface and wipe with an undesired reaction immediately.

2. OPTIONAL: GLUE REMAINS TO REMOVE

case before bonding the fracture adhesive residue must be removed yet, a few drops of the cleaner be applied directly to the glue residue. The cleaner must move in a few minutes and liquefied residues. These can be easily removed with a clean cloth.

3. BASIC CLEANING

For cleaning the breaking point are only applied a few drops of the cleaner at the point where then is stuck. In order to achieve strong adhesion values, it is essential to use a clean cloth and completely remove the cleaner along with dirt. Any contamination degrades the stability of the adhesive bond.

Content:

1x Rugged portable case

1x The weld from the bottle (20g industrial adhesive + 40g granulate)

1x HG-Cleaner / Cleaner and Adhesive Remover (20ml)

1x HG-primer / adhesion promoter for difficult to bond plastics (15ml)

1x HG-activator for brushes / hardening accelerator (15ml)

1x HG activator spray / curing accelerator (200ml)

1x HG-Epoxy Stick / Universal Knetmetall (56g)

Your 4 main benefits at a glance:

QUALITY GIFT: The case is the perfect gift for Father's Day, whether for campers, mechanics, model builders, or for a family man. It is filled with everything a home improvement needed in an emergency.

THE BEST CHOICE FOR COUNTLESS REPAIRS: Whether broken shoe soles, broken china, leaking tanks or extreme breaking points on the car, motorcycle or children's toy: with this case, you always have everything you need on site.

PREMIUM QUALITY: The case is equipped with high-quality adhesive products that you have on hand the right product for almost any application allow.

LIGHTWEIGHT AND PORTABLE: The rugged case is simple and easy to carry, so you always have everything at hand in case of repair.

Der praktische Stick für die schnelle Reparatur!

Montieren, kleben und abdichten mit dem HG Epoxy Stick

Der Epoxy Stick ist eine Reparaturknetmasse, mit der du Ausbesserungsarbeiten schnell und einfach durchführst.

Ein paar Minuten mit der Hand geknetet und diese unscheinbare Masse verwandelt sich in ein regelrechtes Universalgenie.

Nach nur 5 Minuten ist das Material so fest, dass es sich kaum noch verformen lässt. Nach 24 Stunden ist die Masse so hart, dass man hineinbohren oder sogar ein Gewinde hineinschneiden könnte.

Wofür wird das Epoxy eingesetzt?

Der Dübel hält nicht mehr in der Wand? Kein Problem! Die Masse ein paar Minuten kneten und anschließend samt Dübel in das Loch pressen – fertig! Du hast ein Loch in der Regentonne? Kein Ding! Das Epoxy klebt sogar unter Wasser und dichtet deine Tonne wieder ab. Du sparst dir aufwendige Reparaturarbeiten.

Du siehst also: Der Kreativität, das Epoxy sinnvoll einzusetzen, sind keine Grenzen gesetzt. Die Knetmasse eignet sich zum Montieren, Befestigen oder Abdichten. Nach dem Aushärten lässt sich die behandelte Stelle ohne Probleme schleifen, lackieren, bohren usw.

Die Reparaturmasse ist abweisend gegen Wasser, Öl, Benzin und viele anderen Chemikalien. Temperaturbereich: -50°C bis +180°C (kurzfristig bis 300°C)

Anwendung:

1. Reinigung

Jeglichen Schmutz, wie Staub und Fett, von der zu behandelnden Oberfläche entfernen.

2. Folie abziehen

Bevor mit der Knetmasse gearbeitet wird, muss die Schutzfolie rückstandslos entfernt werden.

3. Menge bestimmen

Die benötigte Menge abschätzen und mit einem scharfen Messer vom Epoxy-Stick abschneiden.

4. Kneten

Die benötigte Masse manuell mit der Hand kneten, damit sich die Inhaltsstoffe verbinden und eine Polymerverbindung eingehen (Tipp: Dabei Handschuhe tragen). Wenn das Material warm wird und sich verfärbt, bleiben ca. 5 Minuten zur Verarbeitung des Epoxids.

5. Reparieren und aushärten lassen

Die Reparatur, wie z. B. das Abdichten von Löchern oder das Zusammenkleben kaputter Teile, vornehmen. Nach dem Aushärten kann das Material geschliffen, lackiert und angebohrt werden.

345870 - Epoxy-Stick - 56g

• EIN UNIVERSALGENIE: Das HG Epoxy ist eine vielfältig einsetzbare Knetmasse zum Montieren, Kleben und Abdichten.

• HÄLT AUCH UNTER WASSER: Das Epoxy eignet sich hervorragend zum Stopfen von Löchern und Abdichten von Tanks und Behältern.

• BEARBEITBAR: Das Material wird so hart, dass sich die Stelle beliebig bearbeiten lässt. Du kannst sie schleifen, lackieren und anbohren.

Gefahrenhinweis:

ACHTUG. 4,4'-Methylen diphenyldiglycidylether. Reaktionsprodukte von Pentaerythrit, propoxyliertem und 1-Chlor-2,3-

epoxypropan mit Schwefelwasserstoff. Verursacht Hautreizungen. Verursacht schwere Augenreizung.

Kann allergische Hautreaktionen verursachen. Schädlich für Wasserorganismen, mit langfristiger Wirkung.

Ist ärztlicher Rat erforderlich, Verpackung oder Kennzeichnungsetikett bereithalten.

Darf nicht in die Hände von Kindern gelangen. Schutzhandschuhe / Augenschutz / Gesichtsschutz tragen.

Bei Hautreizung oder -ausschlag: Ärztlichen Rat einholen / ärztliche Hilfe hinzuziehen.

BEI KONTAKT MIT DEN AUGEN: Einige Minuten lang behutsam mit Wasser spülen. Eventuell vorhandene

Kontaktlinsen nach Möglichkeit entfernen. Weiter spülen. Bei anhaltender Augenreizung: Ärztlichen Rat einholen / ärztliche

Hilfe hinzuziehen.Inhalt/Behälter gemäß lokalen/nationalen Vorschriften der Entsorgung zuführen.

Enthält epoxidhaltige Verbindungen. Kann allergische Reaktionen hervorrufen.

UFI: 2E00-V04G-D00J-C2C4

Content:

60.00

Suitable for almost all materials

Our adhesive repair kit the called 'the weld out of the bottle' for good reason. The unique mixture of granules and adhesive industry is many times more efficient than conventional adhesives and welded breaks, cracks, cracks, filling holes and gaps as no adhesive before. Our adhesive repair kit is suitable for almost all materials and is extremely durable with proper treatment. The weld is weather-resistant, cold and heat resistance and furthermore waterproof.

Two components for maximum grip

the weld out of the bottle is supplied in two bottles. One containing the extremely strong industrial adhesive HG-Extreme 1.0, the other the specially tuned granules. Only the combination of the two components results in a chemical reaction that unleashed an indescribable adhesive force. Using the granules can be nachmodellieren also broken brackets or threaded back and even grind.

The application of adhesive repair kit

1. cleaning the surface of

the weld seam from the bottle can only achieve their full adhesive strength when the breaking point is prepared. Ideally, one roughens the surface with sandpaper or wire brush on something and cleans it of any dirt. It must find no dust, rust, grease or adhesive residue and adhesive surfaces must be dry. Only then high bond strength can be guaranteed.

2. GRANULAT trickling

Subsequently, the adherend objects are precisely joined at the fracture site and applying a fine layer of granules. The powder height must not exceed 2 mm. Before adding the industrial glue, no chemical reaction occurs.

3. INDUSTRIAL ADHESIVE APPLICATION

Now, the adhesive industry HG-Extreme 1.0 carefully dropped from the second bottle on the granules, impregnated until all the granules in cement. Once the two components come into contact, it comes to chemical reaction and heat is produced. We always recommend to provide both sides of the break point with a weld, for maximum grip. The more the bonding process is repeated, the more stable the compound is.

4. CONNECTION CURING LET

After a few seconds the weld from the bottle reaches its full adhesive strength. Then, when the chemical reaction is finished, the suture can be sanded immediately be drilled or even painted. Depending on the materials, the ultimate strength of the breaking point may vary.

Content:

15.00

Suitable for almost all materials

Our adhesive repair kit the called 'the weld out of the bottle' for good reason. The unique mixture of granules and adhesive industry is many times more efficient than conventional adhesives and welded breaks, cracks, cracks, filling holes and gaps as no adhesive before. Our adhesive repair kit is suitable for almost all materials and is extremely durable with proper treatment. The weld is weather-resistant, cold and heat resistance and furthermore waterproof.

Two components for maximum grip

the weld out of the bottle is supplied in two bottles. One containing the extremely strong industrial adhesive HG-Extreme 1.0, the other the specially tuned granules. Only the combination of the two components results in a chemical reaction that unleashed an indescribable adhesive force. Using the granules can be nachmodellieren also broken brackets or threaded back and even grind.

The application of adhesive repair kit

1. cleaning the surface of

the weld seam from the bottle can only achieve their full adhesive strength when the breaking point is prepared. Ideally, one roughens the surface with sandpaper or wire brush on something and cleans it of any dirt. It must find no dust, rust, grease or adhesive residue and adhesive surfaces must be dry. Only then high bond strength can be guaranteed.

2. GRANULAT trickling

Subsequently, the adherend objects are precisely joined at the fracture site and applying a fine layer of granules. The powder height must not exceed 2 mm. Before adding the industrial glue, no chemical reaction occurs.

3. INDUSTRIAL ADHESIVE APPLICATION

Now, the adhesive industry HG-Extreme 1.0 carefully dropped from the second bottle on the granules, impregnated until all the granules in cement. Once the two components come into contact, it comes to chemical reaction and heat is produced. We always recommend to provide both sides of the break point with a weld, for maximum grip. The more the bonding process is repeated, the more stable the compound is.

4. CONNECTION CURING LET

After a few seconds the weld from the bottle reaches its full adhesive strength. Then, when the chemical reaction is finished, the suture can be sanded immediately be drilled or even painted. Depending on the materials, the ultimate strength of the breaking point may vary.

here are plastics on the market, here you will be really mad if you try to glue them. This is due to the increased wax layer of these plastics these include, for example, PE or PP. (Like installed in children's toys, lunch boxes, etc.)

If you try to glue such plastics without a primer, it only achieved a slight but no liability proper bonding.

With this primer you can even wax-containing materials such as PE or PP permanently to bond again and bombproof together.

Our advice to you:

We recommend this adhesive to each weld from the bottle - the there comes a time where you encounter such plastics - and without these primers it is not possible to glue them successfully.

PS: The primer has no expiration date, and is even cheaper by 20% in a set with 'the weld oit of the bottle'.

1. roughen surface & PRIMER APPLICATION

In order for feeding the liquid primer deep, it is important to roughen the surface to be bonded something. A fine primer layer is then applied directly to the breaking point by means of the brush. The liquid then changed chemically the surface structure.

2. BONDING PROCESS PERFORM

After a few seconds, the HG-primer has completed his work and evaporates. Now the actual bonding process can be carried out as usual. It should be noted that after applying the primer, the actual ultimate strength of the bond is reached after 24 hours.

HG-activator - The hardening accelerator for professionals

industrial adhesives stick very efficient due to complete absence of oxygen. This is obtained by contact pressure. However, certain materials such as porcelain, stone, tile, wood or ceramic need for bonding without granules often until they are completely cured several hours. Or is very porous, tiny or two non-fit surfaces, so you can not exert a contact pressure. In these cases, the HG-activator causes an extremely rapid bonding. Here our hardening accelerator is specifically tailored to our HG-industrial adhesive. After a few seconds, the breaking point is glued by hand.

The application of the HG-activator

1. Application of the activator

, the curing accelerator may both before and also be applied after the bonding. In the application before bonding one side of the fracture site with the activator is sprayed, the coated other with glue before the two parts are joined together. If the activator spray applied only after the gluing, is previously painted only on one side of the crack HG-industrial adhesive. The two objects were then joined together, the splice is wetted with the hardening accelerator.

2. CURING LET

After a few seconds, the breaking point is glued by hand.

Product information "The weld out of the bottle - Activator for brushing (curing accelerator) - 15ml"

HG-activator - The hardening accelerator for professionals

industrial adhesives stick very efficient due to complete absence of oxygen. This is obtained by contact pressure. However, certain materials such as porcelain, stone, tile, wood or ceramic need for bonding without granules often until they are completely cured several hours. Or is very porous, tiny or two non-fit surfaces, so you can not exert a contact pressure. In these cases, the HG-activator causes an extremely rapid bonding. Here our hardening accelerator is specifically tailored to our HG-industrial adhesive. After a few seconds, the breaking point is glued by hand.

The application of the HG-activator

1. APPLY the activator AND INDUSTRY CEMENT

The hardening accelerator is only applied to one side of the fracture. For this purpose the surface must only be wetted with a fine layer of liquid. HG-industrial adhesive is applied to the second side of the crack.

2. APPLICATION OF GLUE INDUSTRY

then the two objects are joined. After a few seconds, the breaking point is hand-glued

industrial adhesives stick very efficient due to complete absence of oxygen. This is obtained by contact pressure. However, certain materials such as porcelain, stone, tile, wood or ceramic need for bonding without granules often until they are completely cured several hours. Or is very porous, tiny or two non-fit surfaces, so you can not exert a contact pressure. In these cases, the HG-activator causes an extremely rapid bonding. Here our hardening accelerator is specifically tailored to our HG-industrial adhesive. After a few seconds, the breaking point is glued by hand.

The application of the HG-activator

1. APPLY the activator AND INDUSTRY CEMENT

The hardening accelerator is only applied to one side of the fracture. For this purpose the surface must only be wetted with a fine layer of liquid. HG-industrial adhesive is applied to the second side of the crack.

2. APPLICATION OF GLUE INDUSTRY

then the two objects are joined. After a few seconds, the breaking point is hand-glued