-

Tools/supplies

-

Drilling, polishing, grinding

-

Drilling, milling

-

Boxes and socket

- Milling cutter

-

Lapping machine

-

Polishing

-

Polishing for hand pieces

-

Grinding

-

Drilling, milling

-

Turning

-

Facilities, compressed air and vacuum

-

Goldsmith special tools/GRS

-

Small tools

-

Soldering, melting, casting, welding

-

Measuring and testing

-

Surface treatment

-

Clean, dry, turning, sawing

-

CAD-software / software

-

Watchmaker tools

-

Sales and workshop tools

-

3D Werkzeuge & Reinigung

-

Drilling, polishing, grinding

slide 2 of 8

slide 1 to 5 of 8

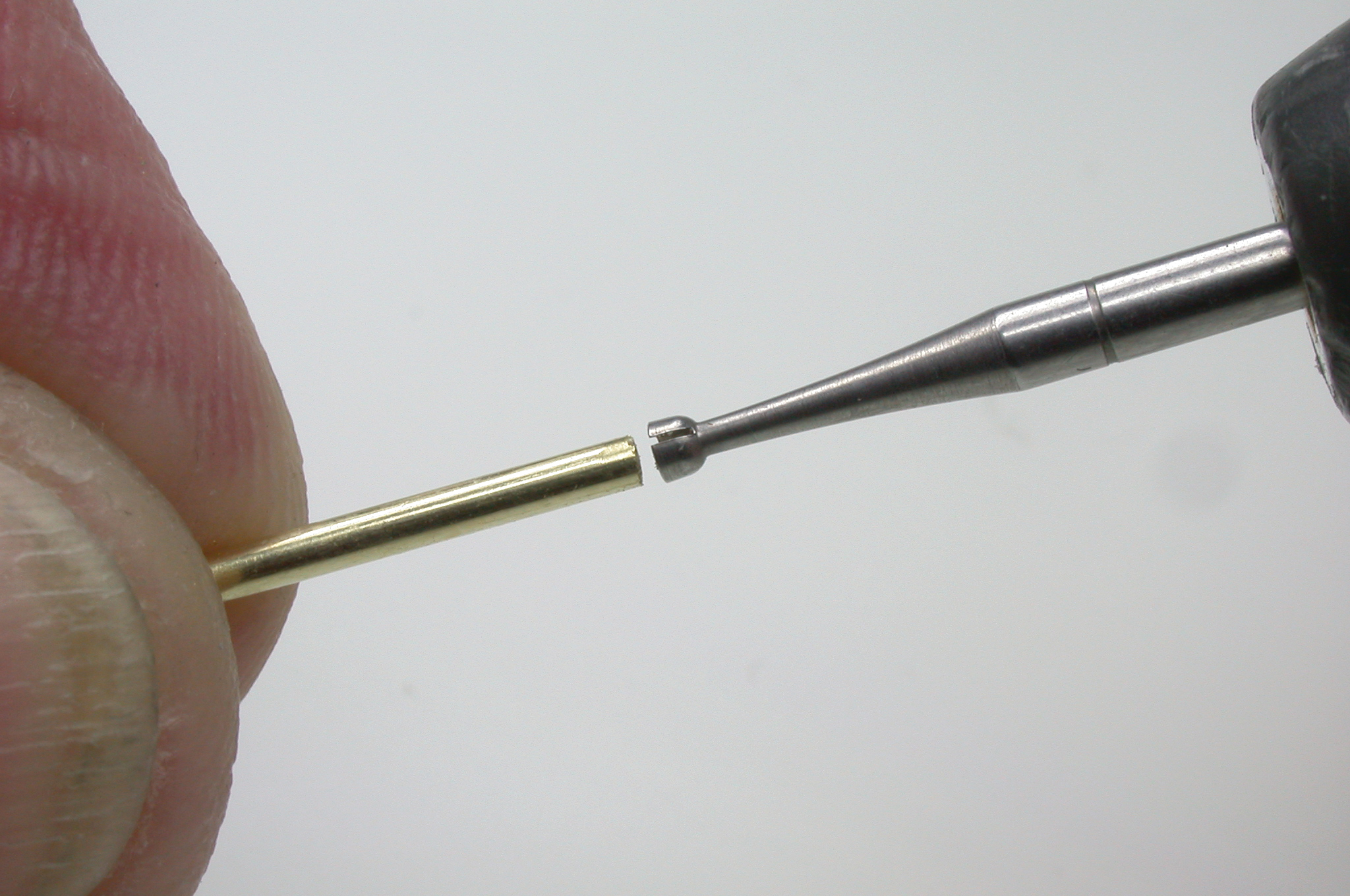

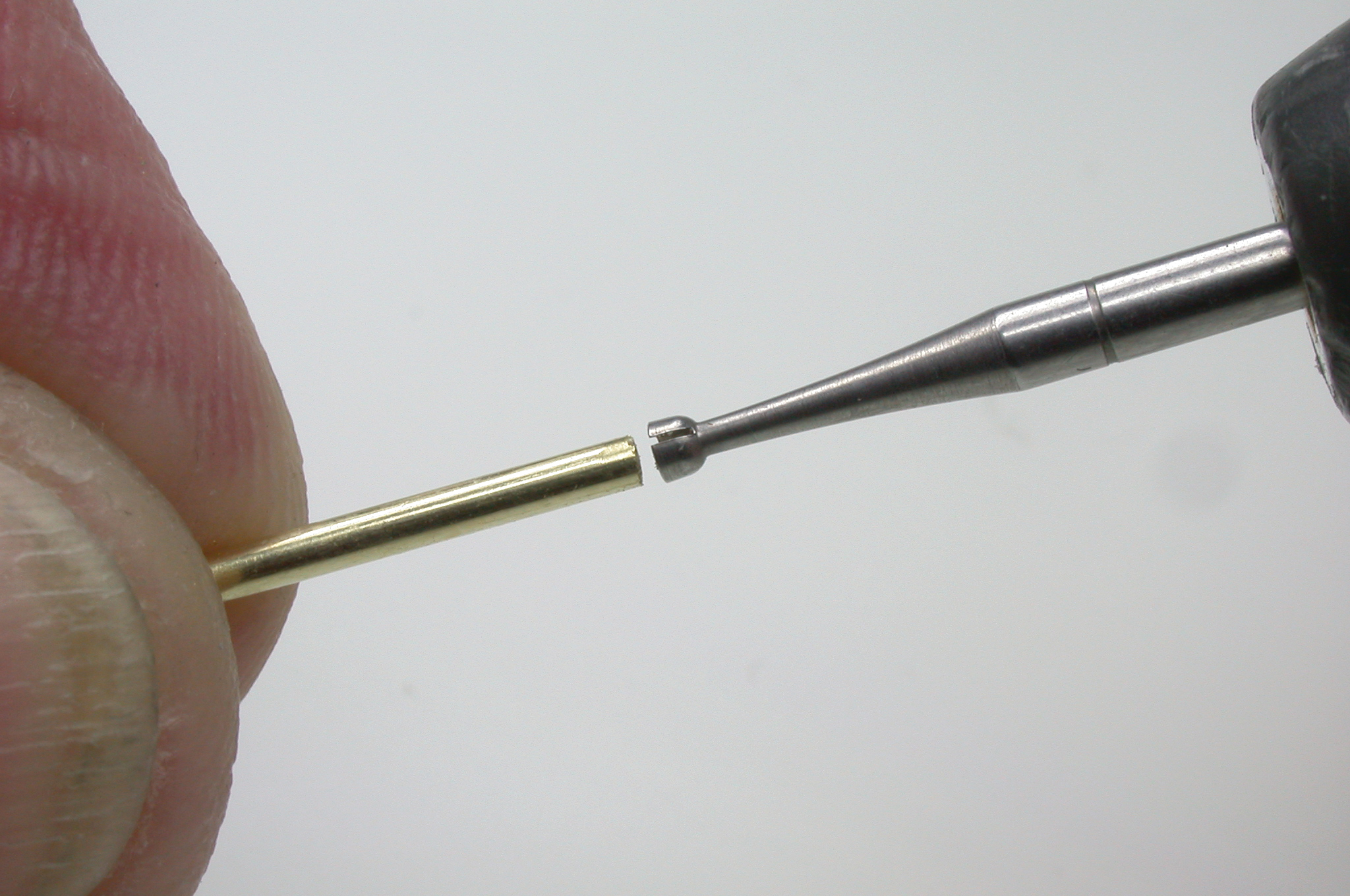

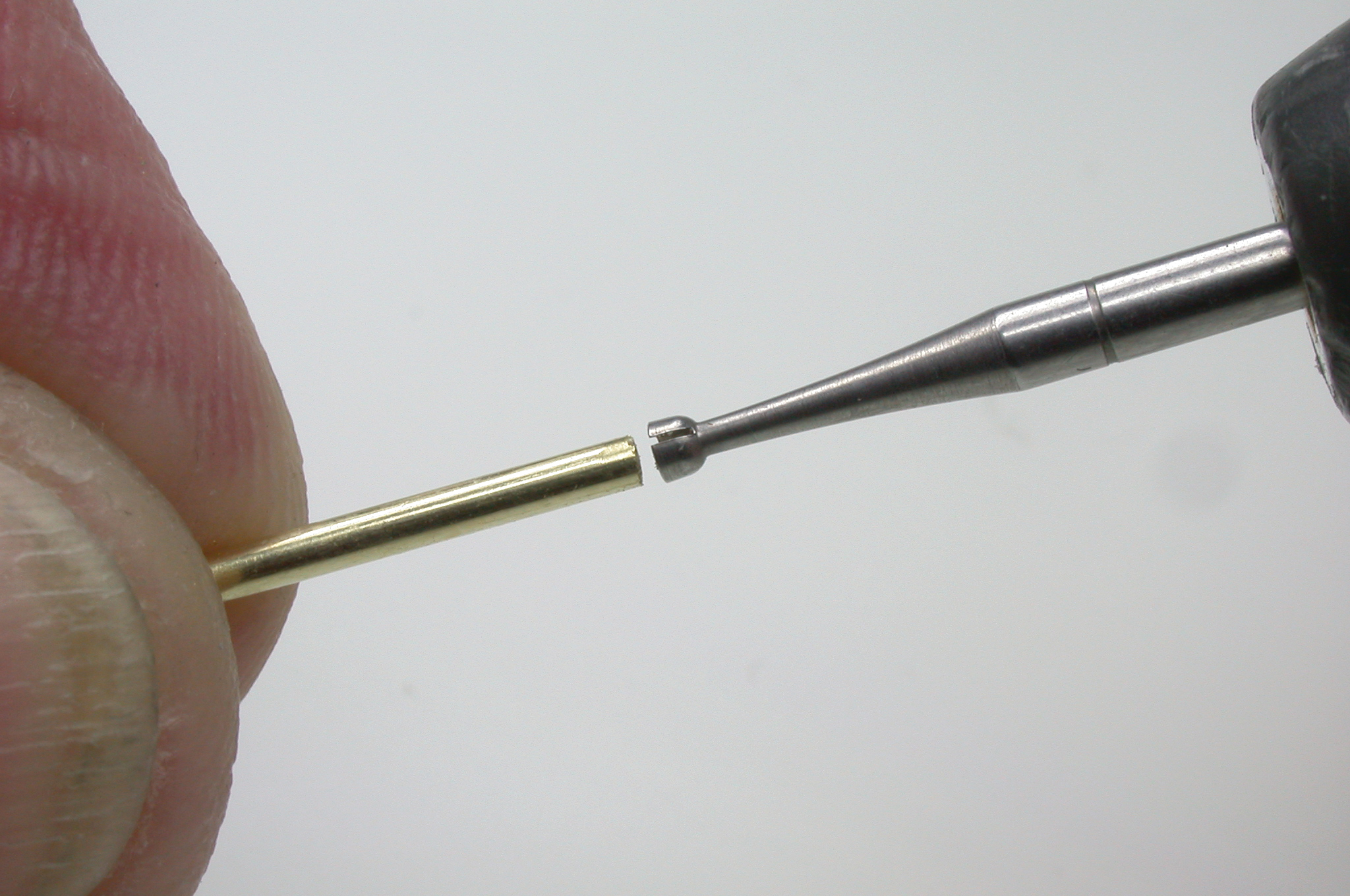

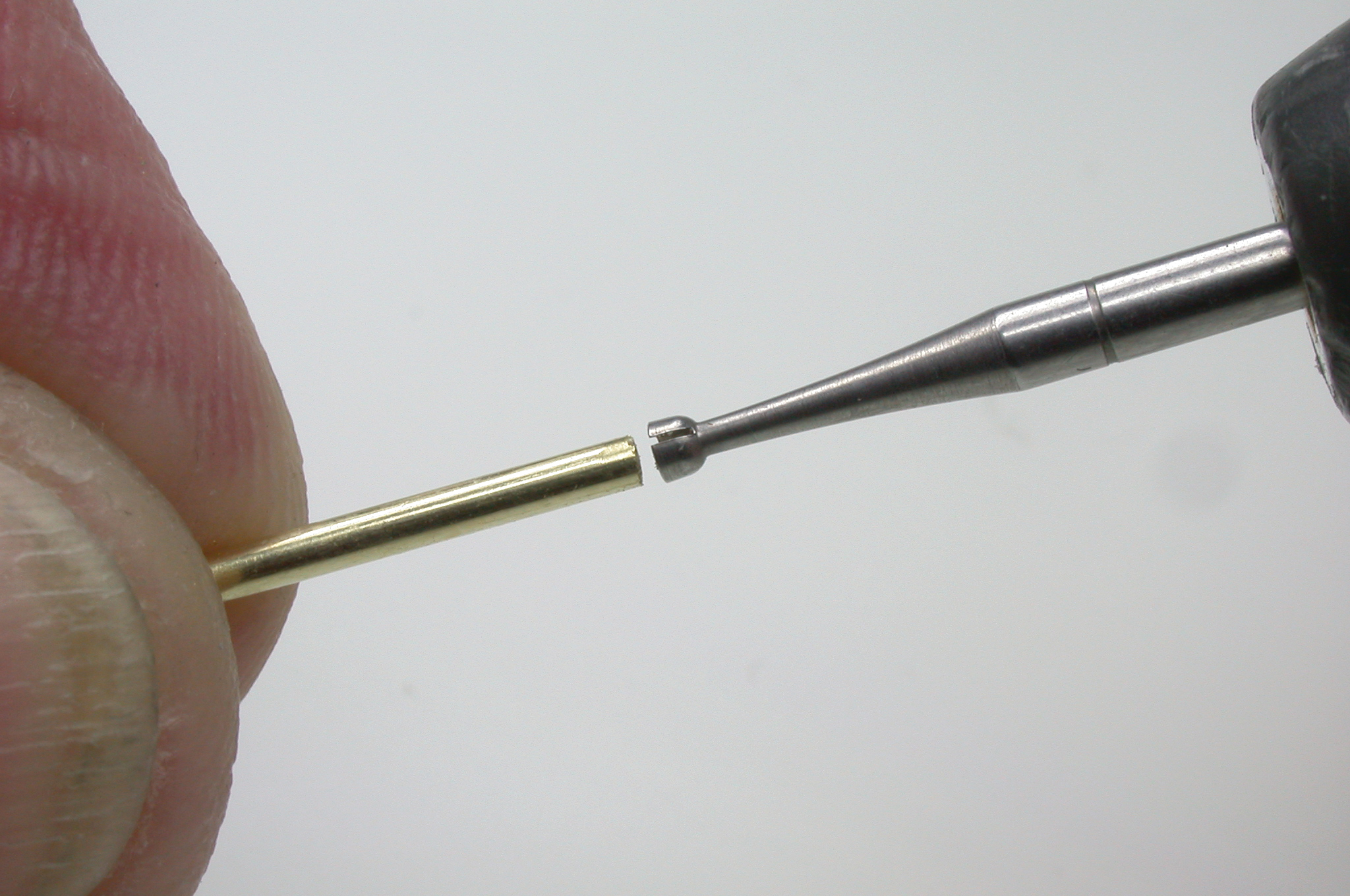

Concave cutter Twincut 1,9mm

Product number:

346017

Packaging Unit:

6

From Stock

| Article name: | Hohlfräser Twincut |

|---|---|

| Brand: | Busch |

| Head length mm: | 1,42 |

| Head Ø mm: | 1,90 |

| Manufacturer name: | Figur 411 T |

| Material: | Werkzeugstahl |

| Shank Ø mm: | 2,35 |

| Unité d'emballage petite: | 6 |

Manufacturer Informations

Name: Busch & Co. GmbH&Co.KG

Street: Unterkaltenbach 17-27

City: 51766 Engelskirchen

Country: DE

Email: mail@busch.eu

Phone: +49 (0) 22 63 - 86 - 0

0 of 0 reviews

Login

No reviews found. Be the first to share your insights.

Product information "Concave cutter Twincut 1,9mm"

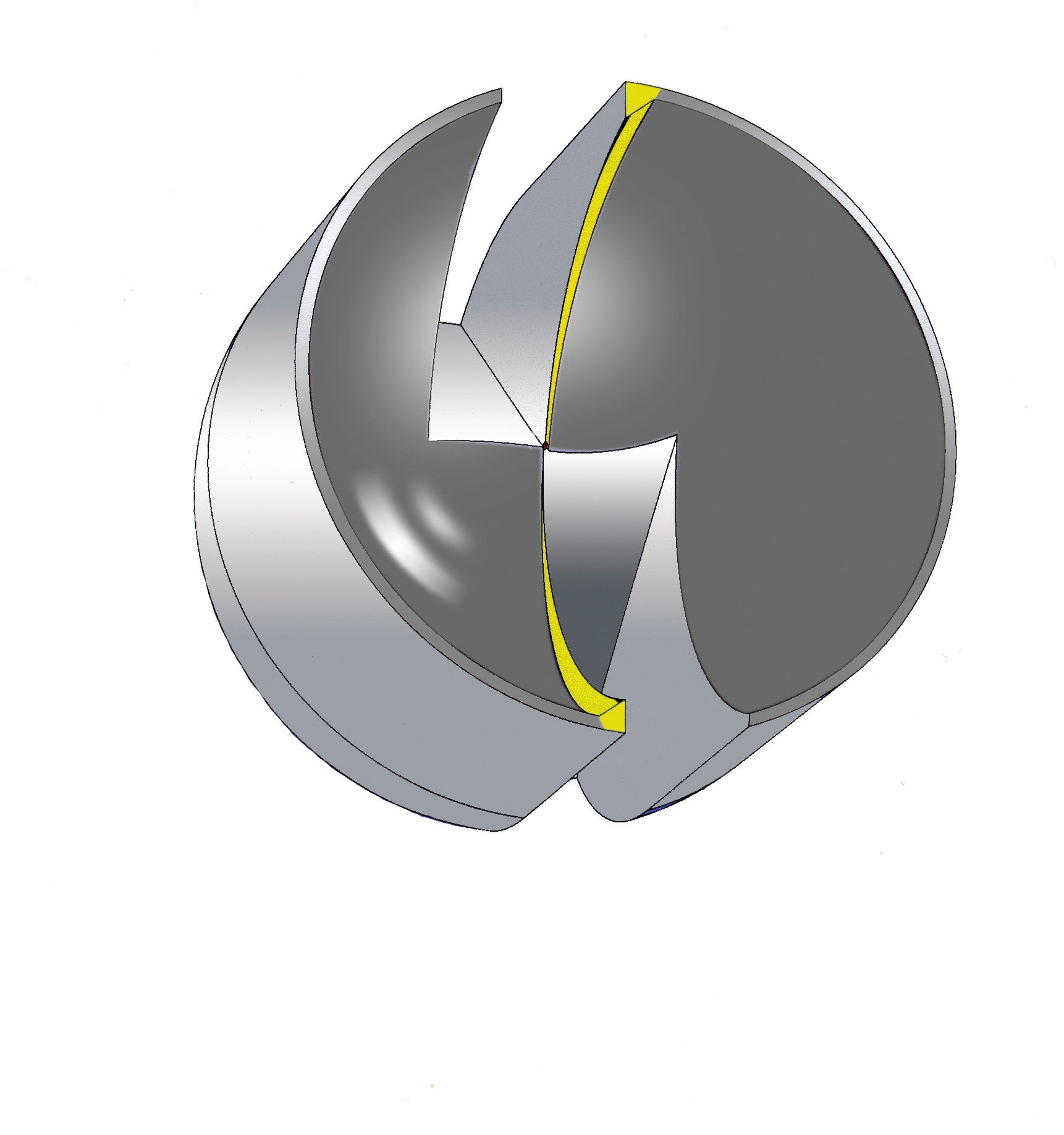

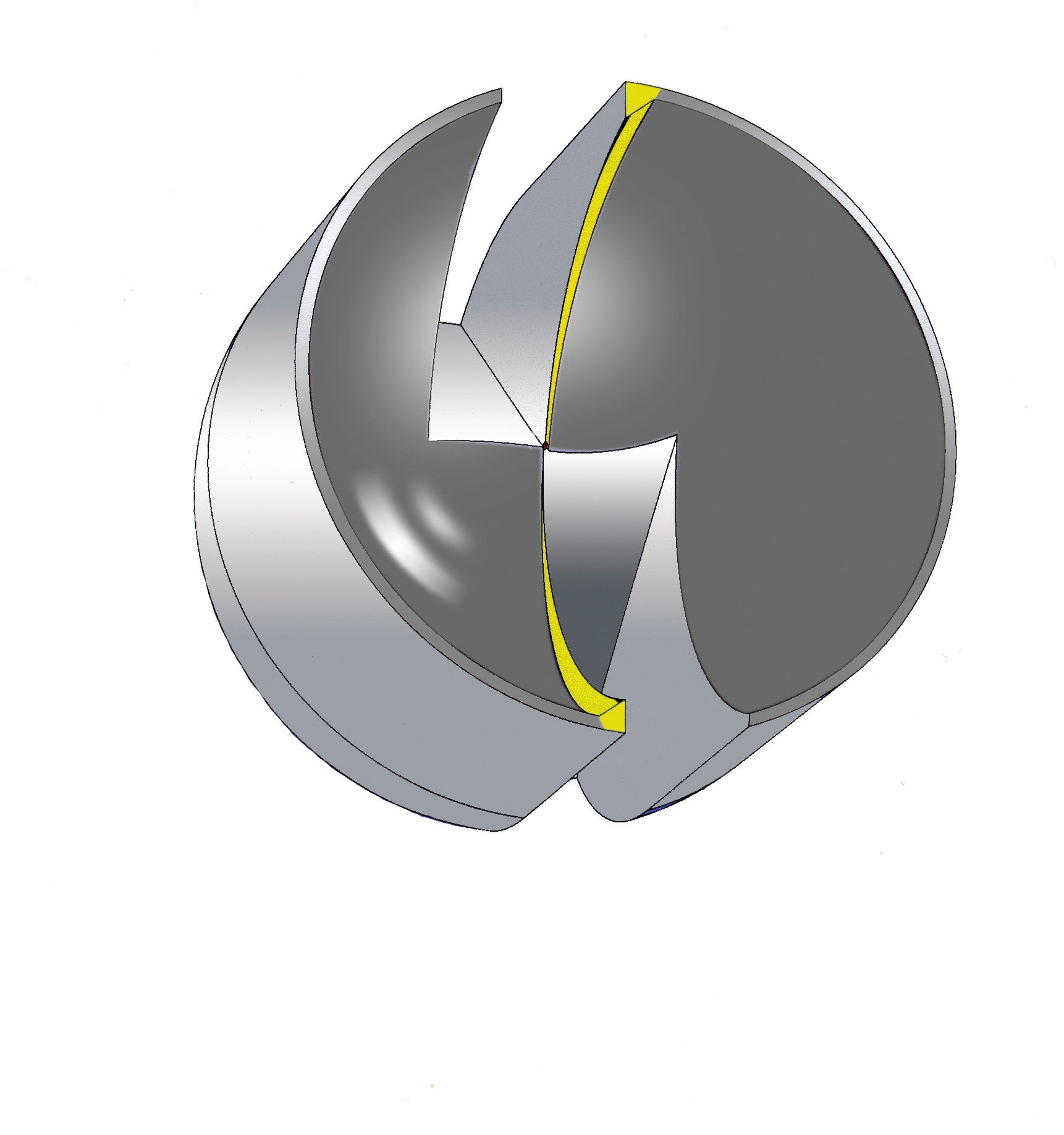

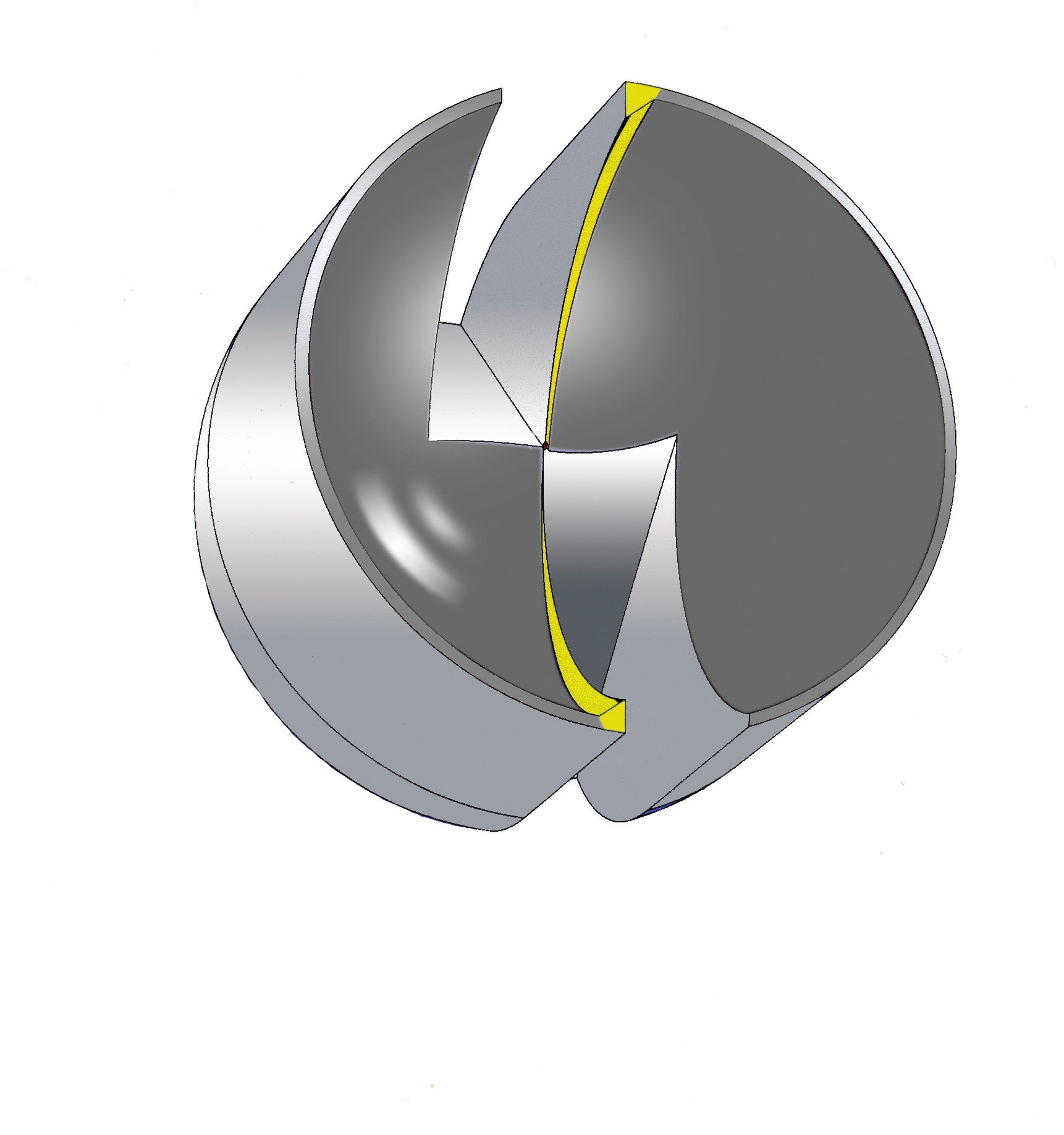

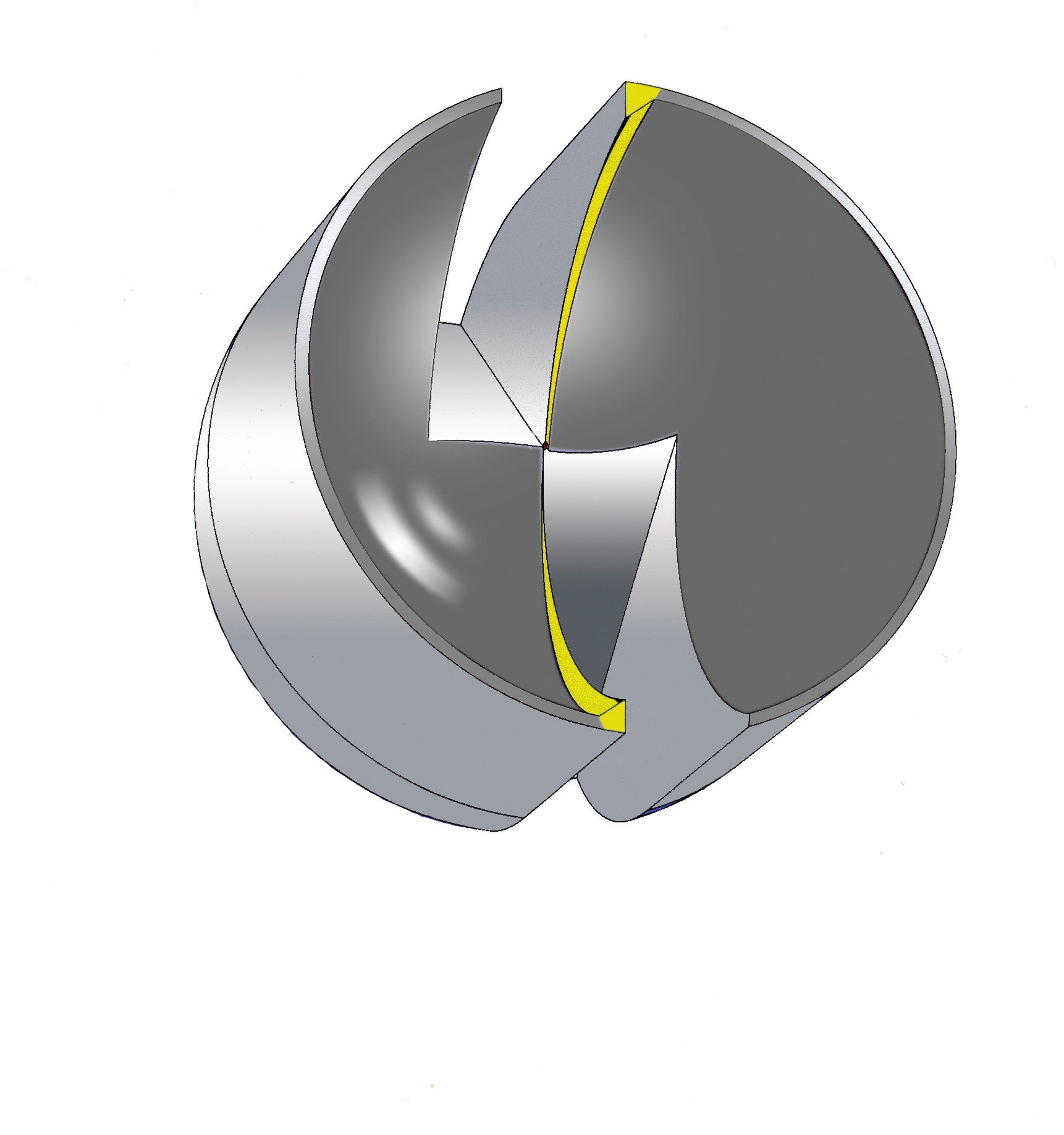

The concave cutter from BUSCH with outstanding TWINCUT blade geometry for quick and precise working. The TOP tool for your chatons.

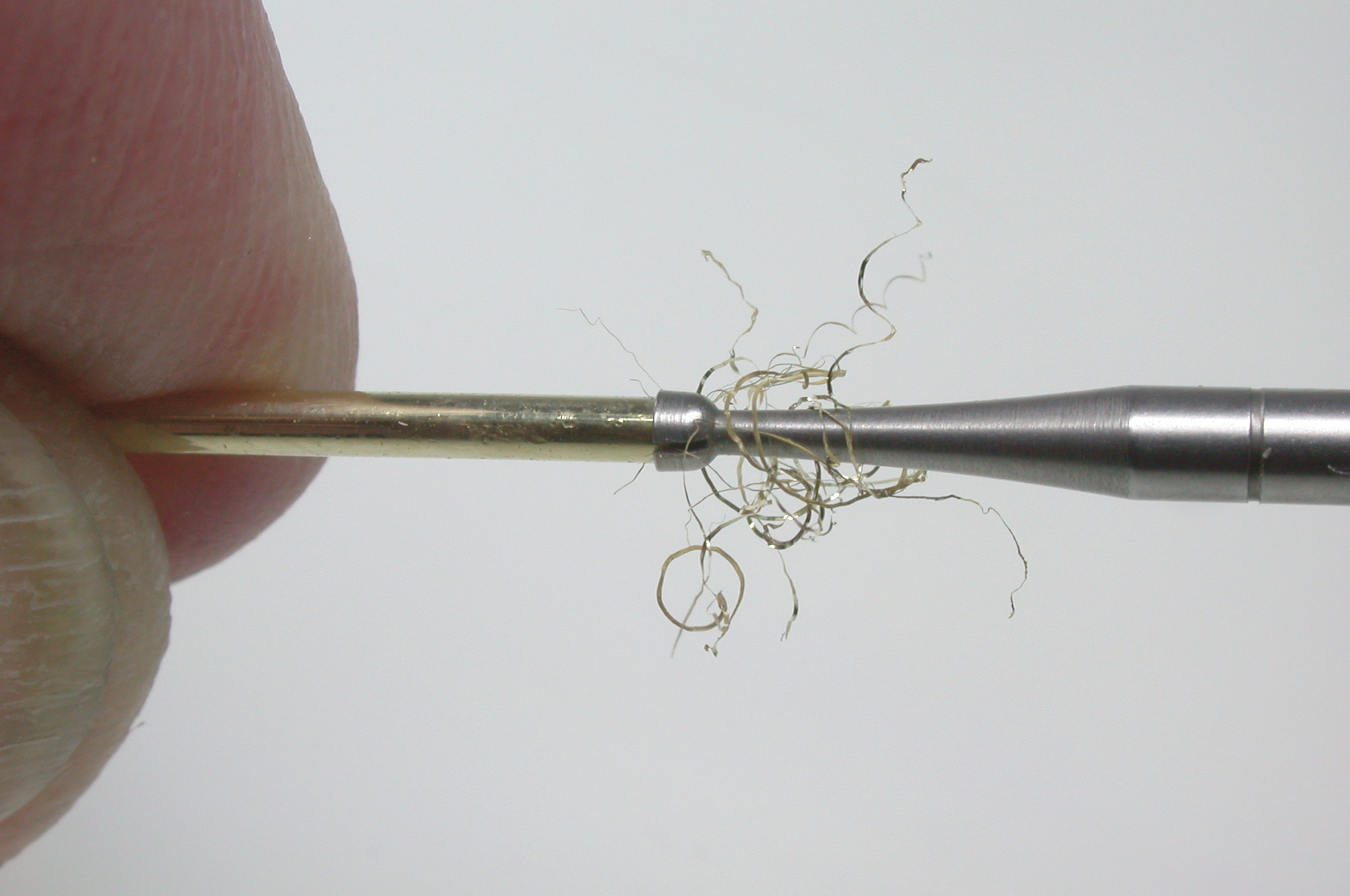

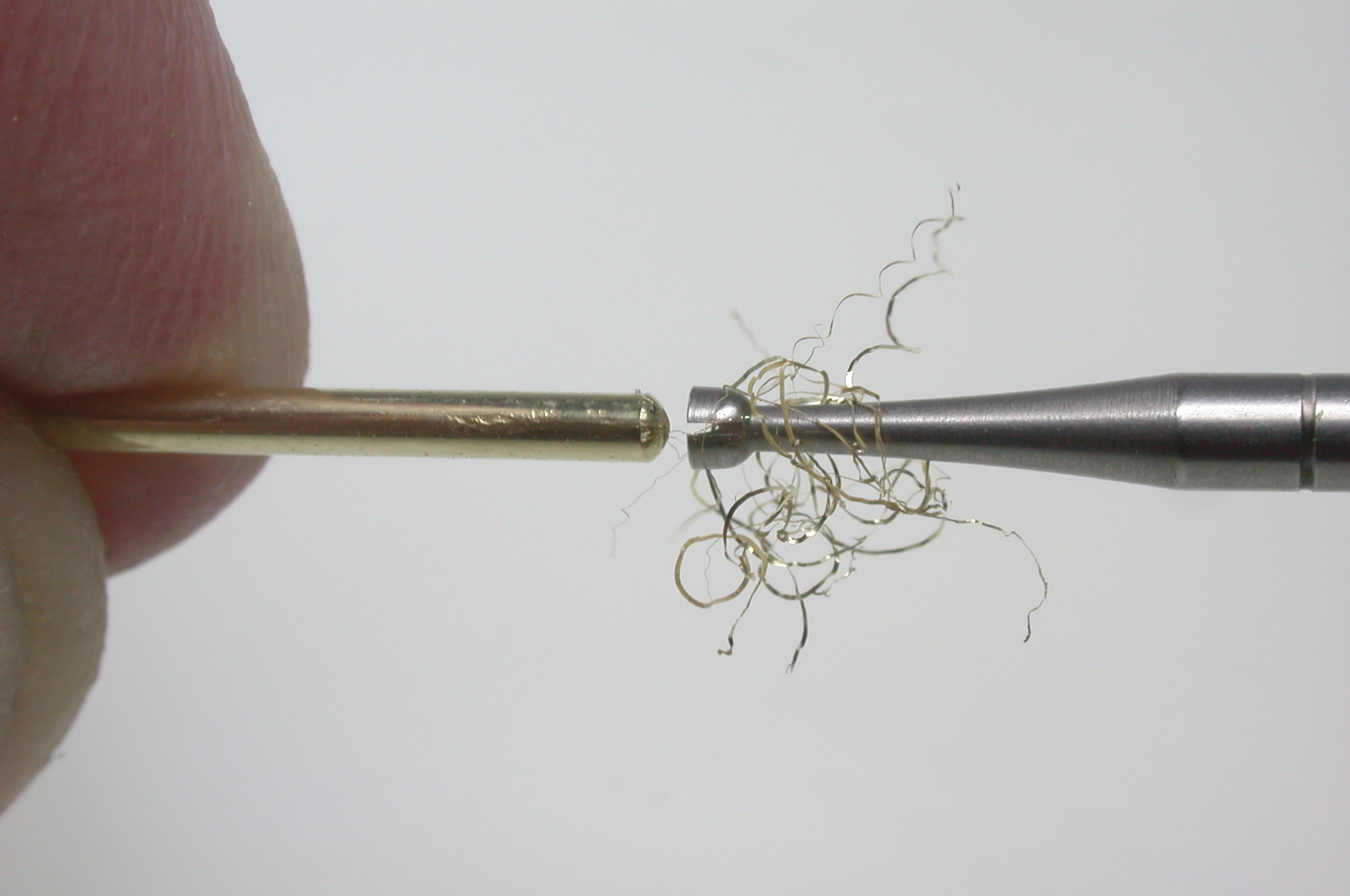

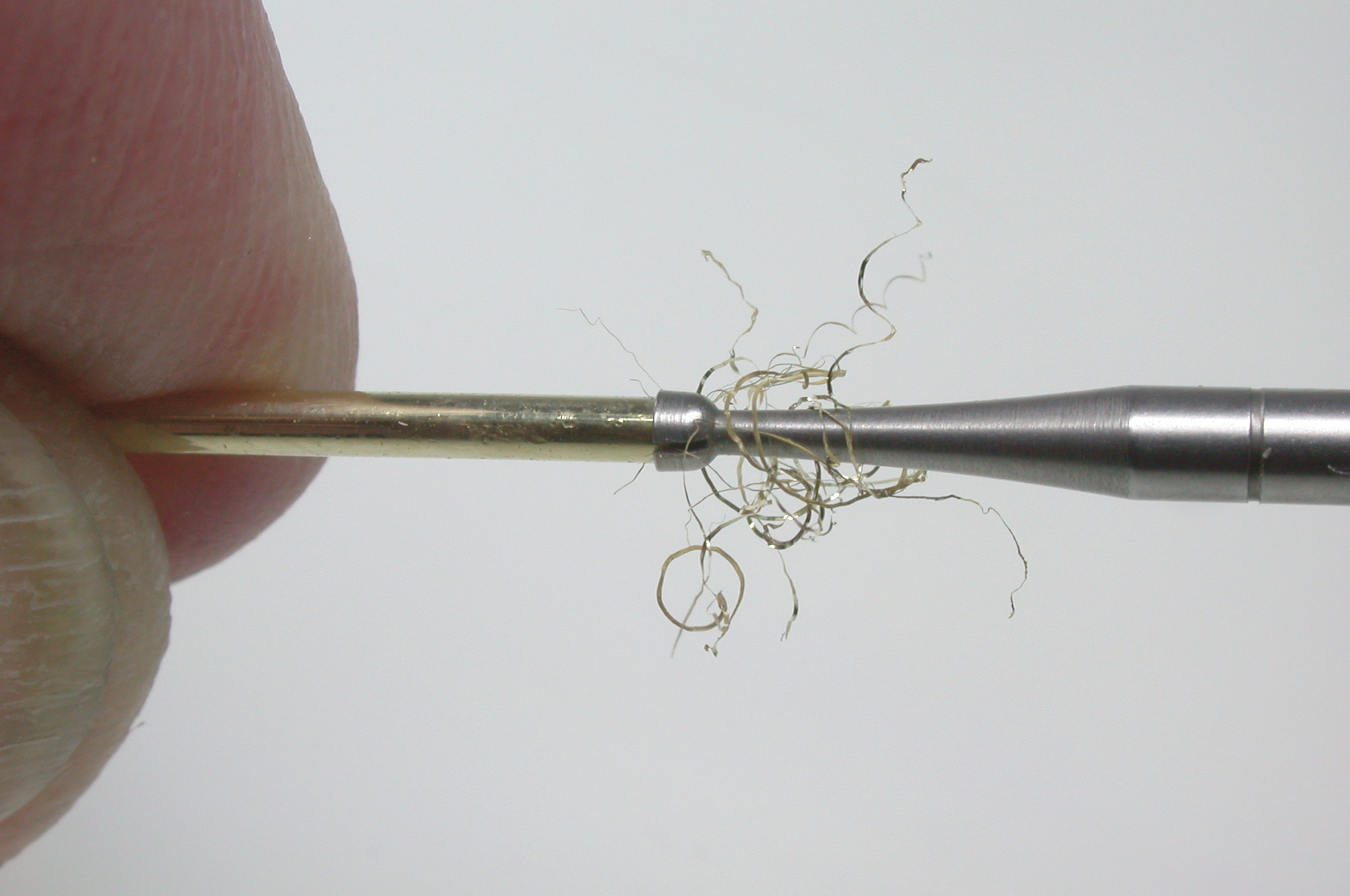

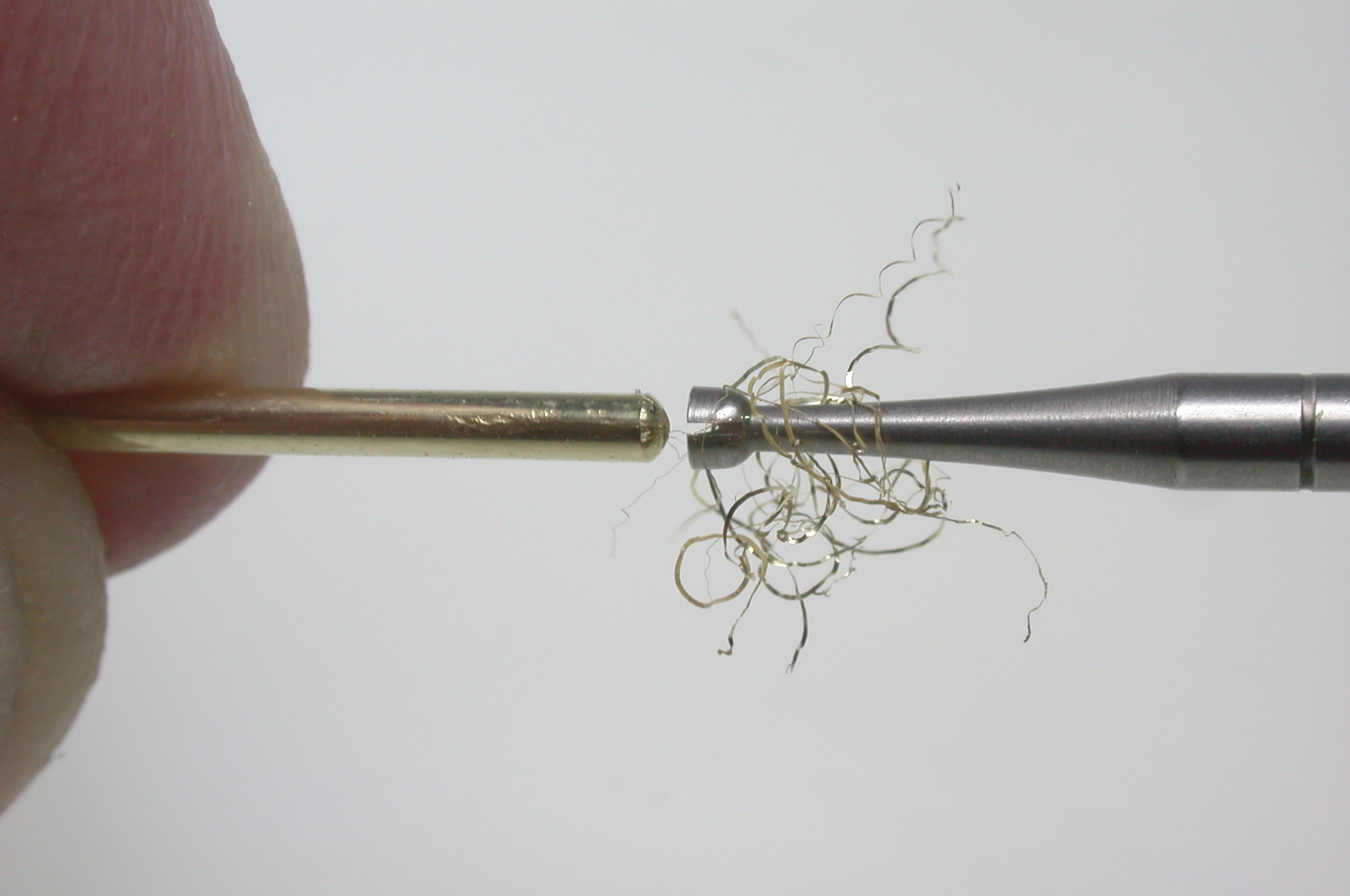

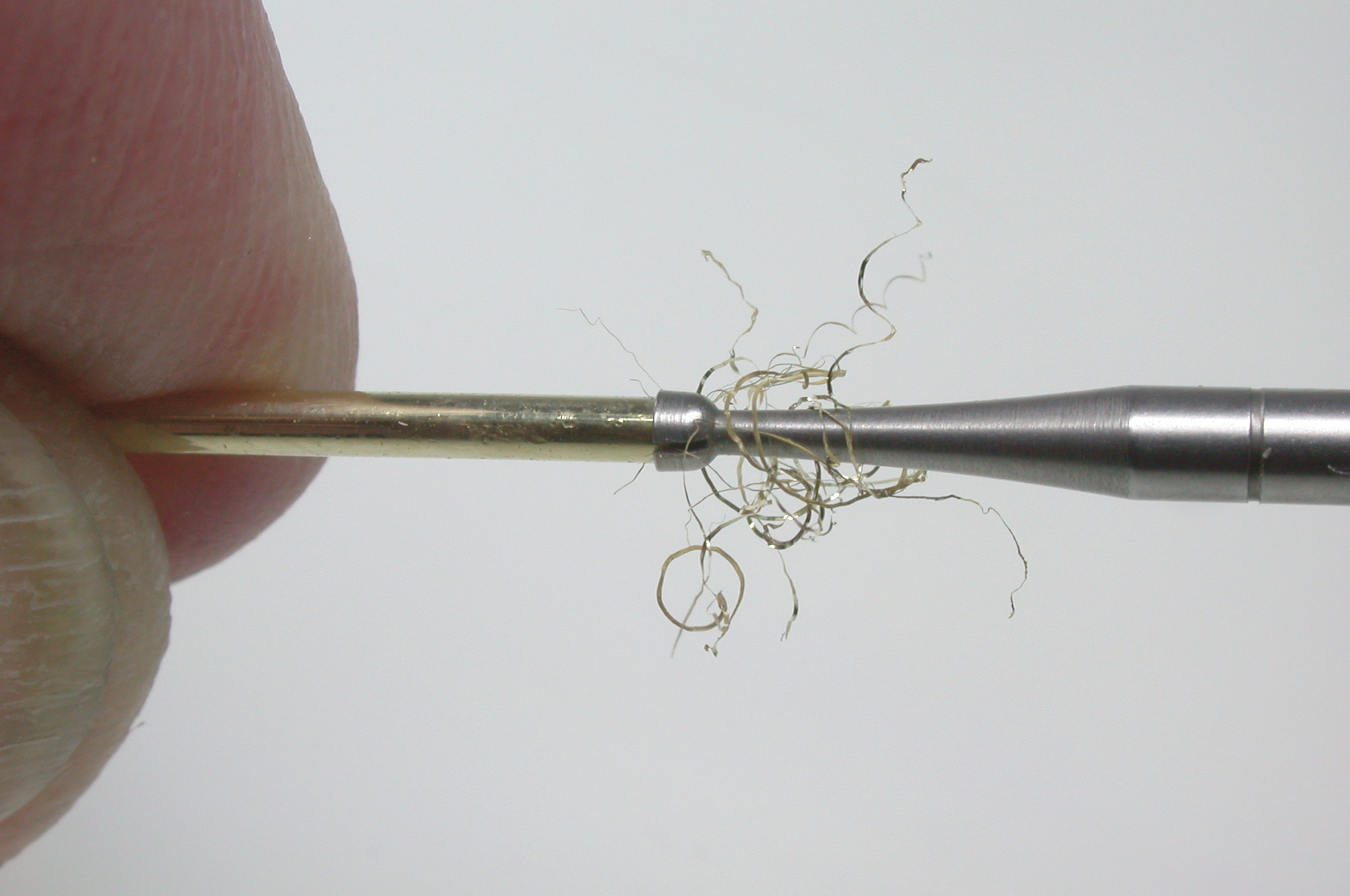

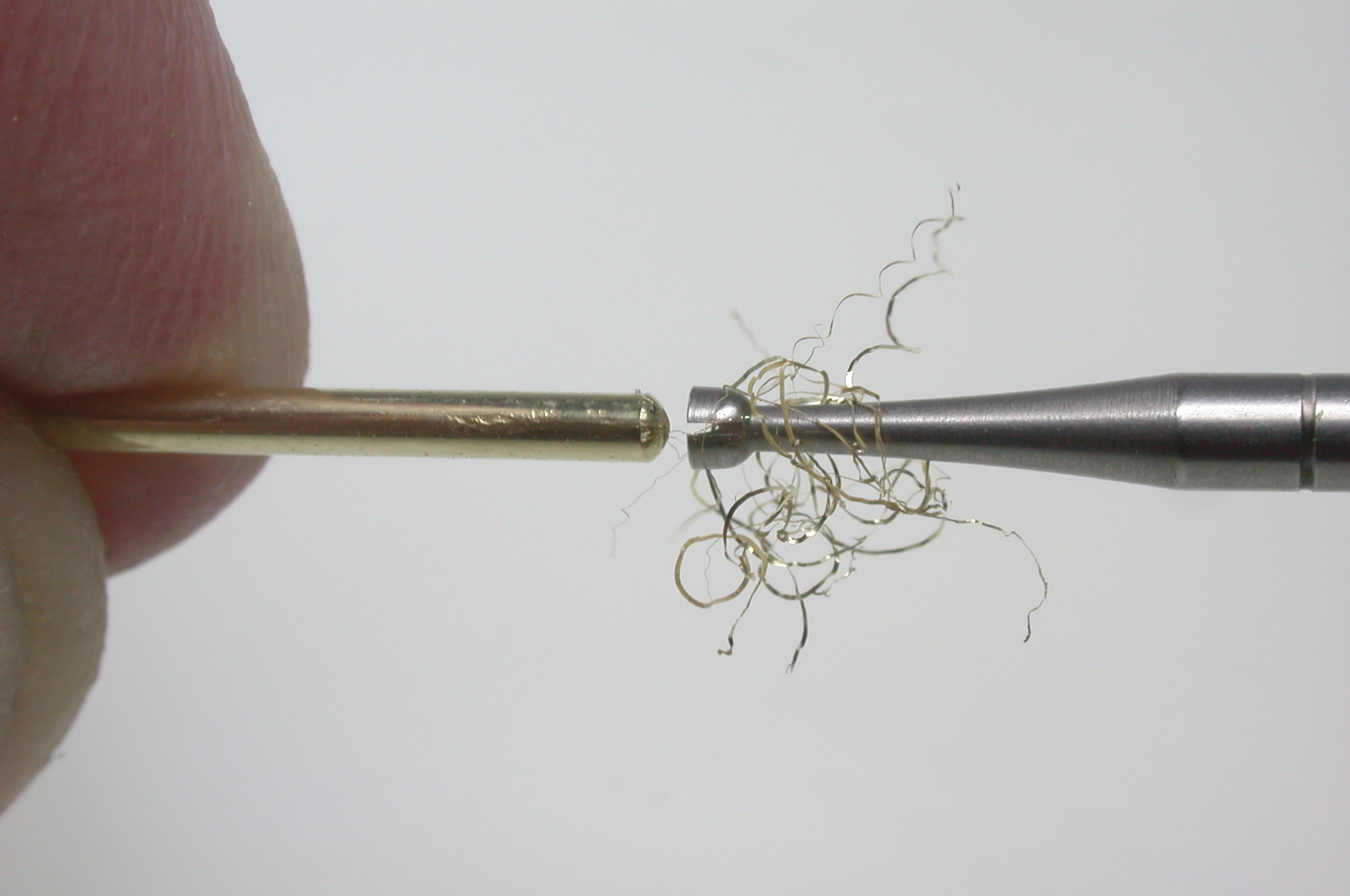

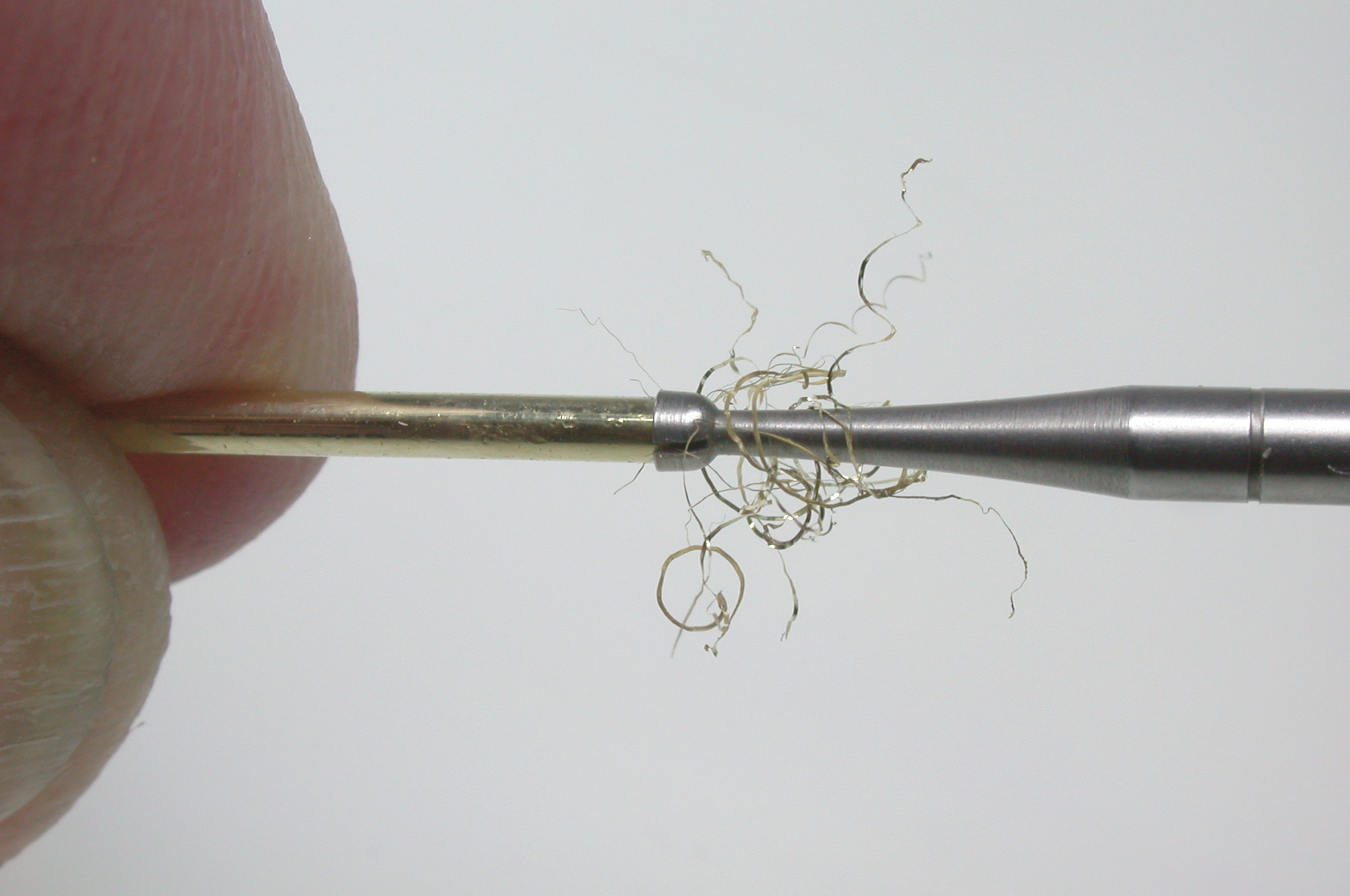

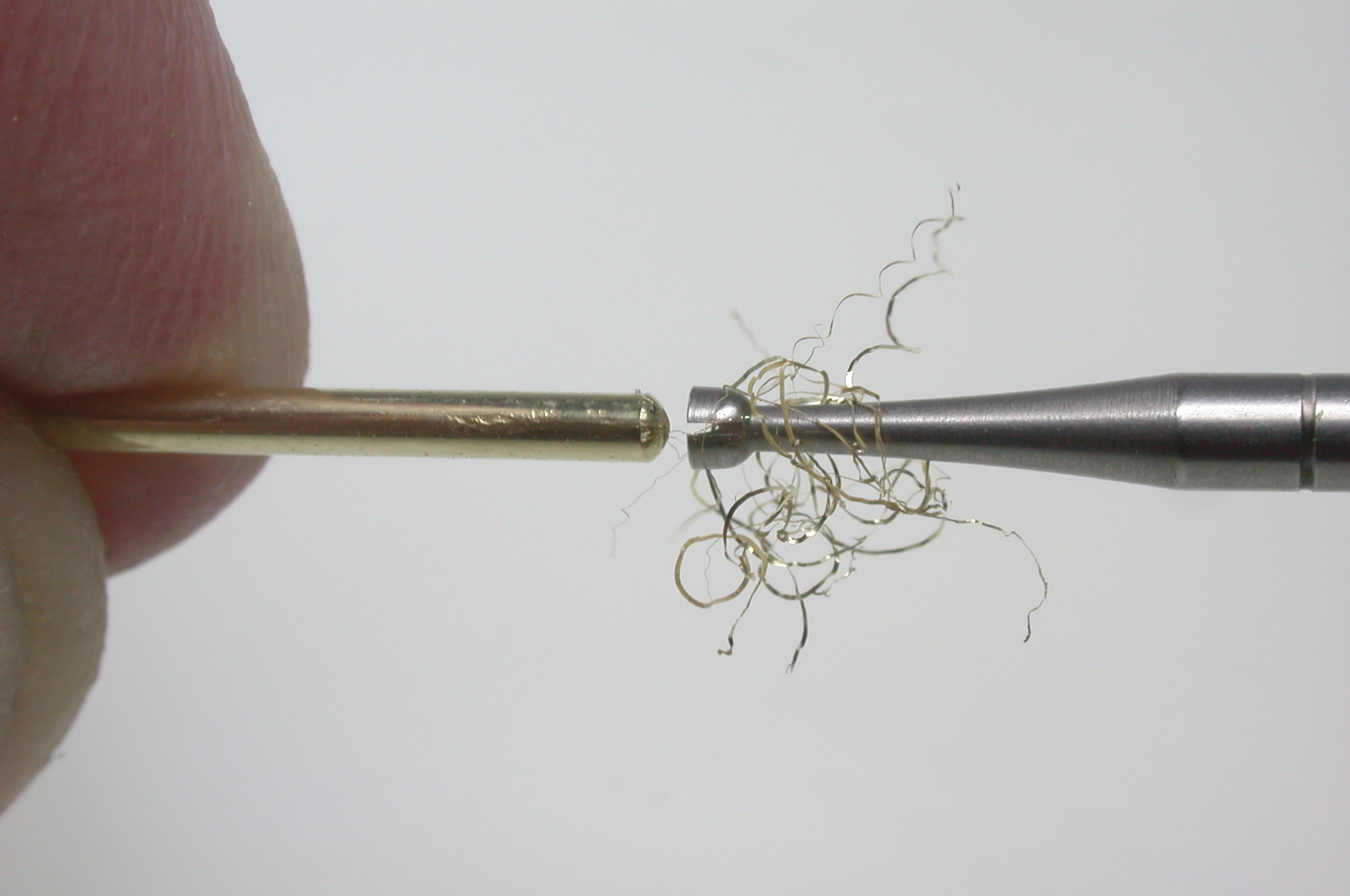

Chatons comprise several sharp-edged claws which have to be rounded-off, smoothened and shortened if necessary. With the TWINCUT concave cutters, the three steps can be undertaken quickly and safely in a single operation.

Special advantages of TWINCUT:

- Rapid removal of material due to the new TWINCUT blade geometry

- Rapid discharge of material through two chip channels

- Easy handling: simply position the tool and start with low pressure

- Filigree cutter walls create additional room for closely spaced claws

- High cost-efficiency due to the robust TWINCUT blade geometry

Chatons comprise several sharp-edged claws which have to be rounded-off, smoothened and shortened if necessary. With the TWINCUT concave cutters, the three steps can be undertaken quickly and safely in a single operation.

Special advantages of TWINCUT:

- Rapid removal of material due to the new TWINCUT blade geometry

- Rapid discharge of material through two chip channels

- Easy handling: simply position the tool and start with low pressure

- Filigree cutter walls create additional room for closely spaced claws

- High cost-efficiency due to the robust TWINCUT blade geometry