- Tools/supplies

Sandblaster

Product number:

242082

Packaging Unit:

1

Extra order! Delivery time approx. 2 weeks, return is not possible.

| Article name: | Sandblaster |

|---|---|

| Brand: | Renfert |

| Content: | 1 |

| Dimensions height mm: | 270 |

| Dimensions width mm: | 470 |

| External dimension length: | 350 |

| Grain size: | 25-70 µ |

| Manufacturer name: | Basic classic |

| Special feature: | 0,8 |

| Unit content: | Tank |

| Volt/Hz: | 230 / 50 |

0 of 0 reviews

Login

No reviews found. Be the first to share your insights.

Accessoires (optional)

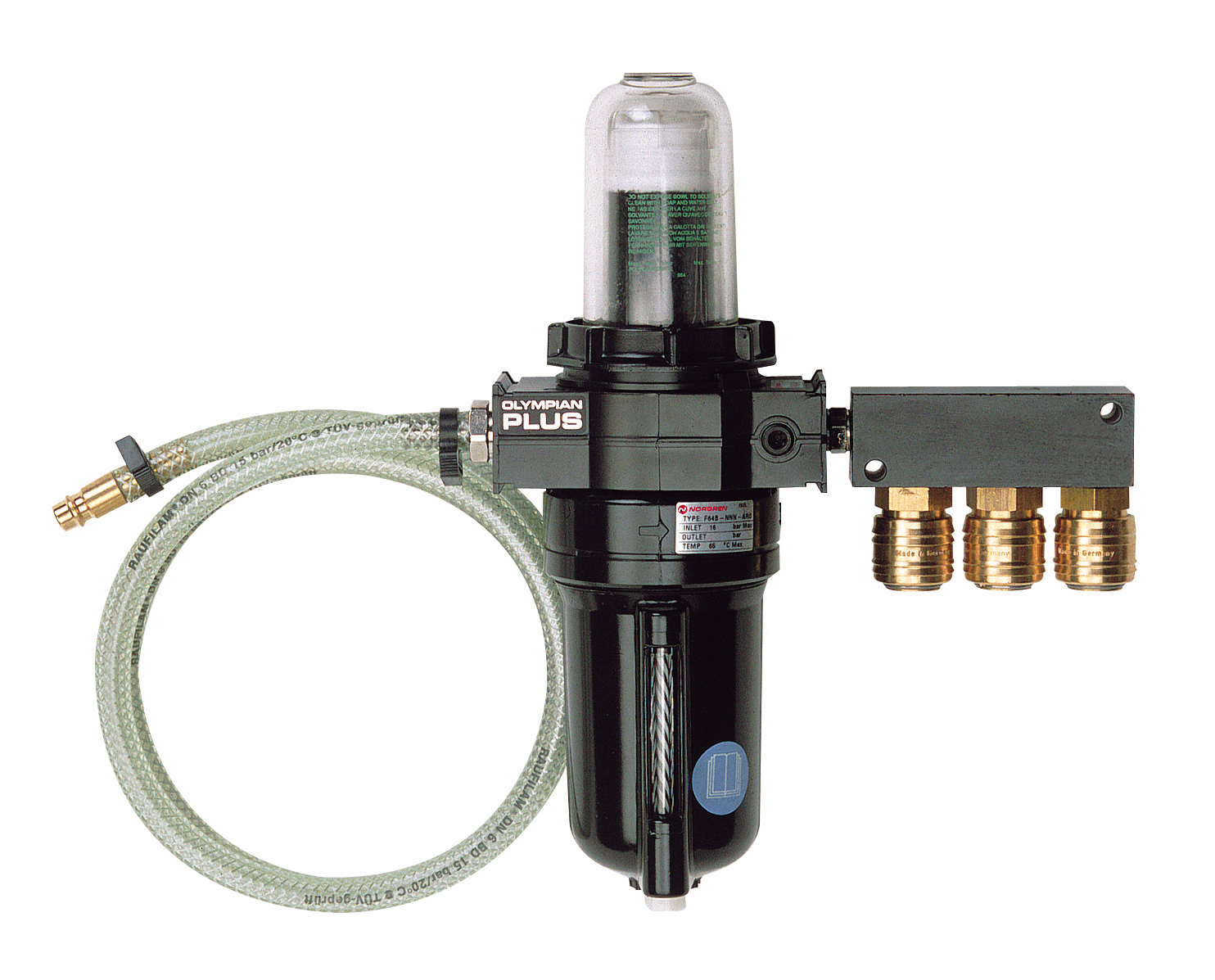

Measuring range:

16 bar

Oil-lubricated compressors, almost noise-free (whisper quiet), max. 48 dB (at 1 m distance), user-friendly, minimum maintenance, corrosion protection in the boiler, handy and easy to carry. The compressors are built as a complete air compressor unit and are equipped with heat switch-off, water separator, adjustable pressure regulator, quick coupling, safety valve, pressure gauge on the boiler and manually adjustable shut-off valve for condensate draining. br 230 V / 50 Hz, 680 Watt.

Three-stage filter system: - Prefilter: solid particles up to 40 ? - Fine filter: smallest solid particles and water droplets up to 0.01 ? - Activated carbon filter: oil up to a residual content of 0.003 ppm Perfectly reliable filtration of water, oil and dirt particles to avoid clumping of the blasting sand due to contamination of the compressed air.

Performance:

44 l/min

Oil-lubricated compressors, almost noise-free (whisper quiet), max. 40 to 55 dB (at 1 m distance), user-friendly, minimum maintenance, corrosion protection in the boiler, handy and easy to carry. Air suction capacity 50 L/min Air delivery capacity 32 l/min The compressors are built as a complete air compressor unit and are equipped with heat switch-off, water separator, adjustable pressure regulator, quick coupling, safety valve, pressure gauge on the boiler and manually adjustable shut-off valve for condensate draining. br 230 V / 50 Hz, 340 Watt.

Article name:

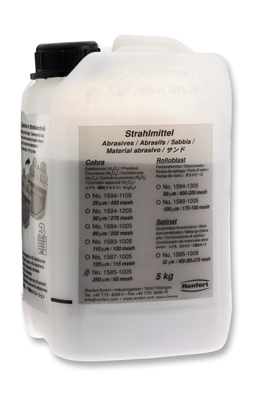

Blasting abrasive Cobra 50 ?

Colour: white. Slightly abrasive with low surface roughness. Gentle removal of oxides.

Article name:

Blasting abrasive Rolloblast 50 ?

For smoothing and polishing metals, achieves a satin sheen, removes dirt and moulding compound.

Article name:

Blasting abrasive Rolloblast 100 ?

For gentle blasting of moulding compounds as well as smoothing and polishing of metal surfaces.

Article name:

Blasting abrasive Cobra 125 ?

Colour: rose. Effective removal with medium roughness.

Article name:

Blasting abrasive Cobra 250 ?

Colour white. Very abrasive. For large-scale removal of investment materials and for the removal of hard oxide layers.

Replacements

Product information "Sandblaster"

Compact blasting devices for all common blasting work

Powder-coated metal case with large, hinged visor. LED lights 4800 Lux for optimum illumination of the blasting chamber. Hose connection for standard quick coupling for connecting the external compressor with connection pressure 6 - 10 bar; intake nozzle for external extraction (internal dia. 35 mm, OD 40 mm).

Features

(a) 1 pressure regulator for individual adjustment of the jet pressure (pressure 1- 6 bar) as well as one tank selector switch each within the blasting chamber

(b) 1 pressure gauge, indicating the jet pressure

(c) integrated water separator to prevent residual moisture in the compressed air

(d) highly resistant IT blasting nozzles made of tungsten carbide

(e) easily accessible, flat footswitch, operable from all directions (360° technology)

(f) colour coding system on the tank cap, tank, and blasting handles facilitates assignment

(g) cuffs washable and replaceable

(h) easy retrofitting of tank from 1-tank devices to 2-tank device

The blasting unit requires an external compressor.

Compressor specification: 100 litres/min minimum. Suction, 6 bar pressure, micro filter 0.01?.

If the (spent) blasting material is to be sucked out automatically, a suction device is also required (see under suction for blasting agents). The sandblasting devices "basic classic" can be retrofitted without tools to include a second tank for blasting agents. Optional: Viewing window also available with special coating. Removable floor grating for disposal of coarse blasting residues.

Lighting connection: 230 V / 50 Hz

Powder-coated metal case with large, hinged visor. LED lights 4800 Lux for optimum illumination of the blasting chamber. Hose connection for standard quick coupling for connecting the external compressor with connection pressure 6 - 10 bar; intake nozzle for external extraction (internal dia. 35 mm, OD 40 mm).

Features

(a) 1 pressure regulator for individual adjustment of the jet pressure (pressure 1- 6 bar) as well as one tank selector switch each within the blasting chamber

(b) 1 pressure gauge, indicating the jet pressure

(c) integrated water separator to prevent residual moisture in the compressed air

(d) highly resistant IT blasting nozzles made of tungsten carbide

(e) easily accessible, flat footswitch, operable from all directions (360° technology)

(f) colour coding system on the tank cap, tank, and blasting handles facilitates assignment

(g) cuffs washable and replaceable

(h) easy retrofitting of tank from 1-tank devices to 2-tank device

The blasting unit requires an external compressor.

Compressor specification: 100 litres/min minimum. Suction, 6 bar pressure, micro filter 0.01?.

If the (spent) blasting material is to be sucked out automatically, a suction device is also required (see under suction for blasting agents). The sandblasting devices "basic classic" can be retrofitted without tools to include a second tank for blasting agents. Optional: Viewing window also available with special coating. Removable floor grating for disposal of coarse blasting residues.

Lighting connection: 230 V / 50 Hz